RUNNING ADJUSTMENTS

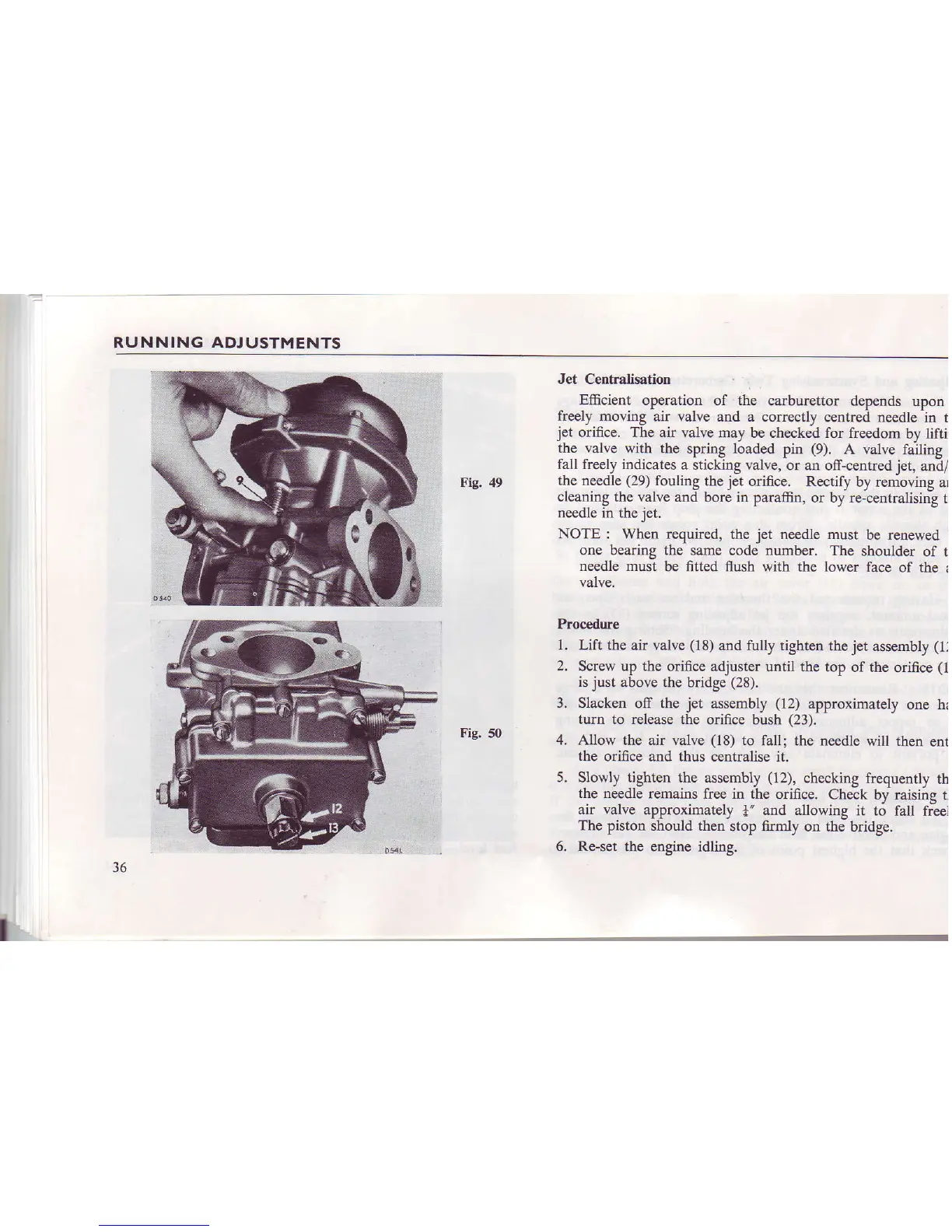

Eie. 49

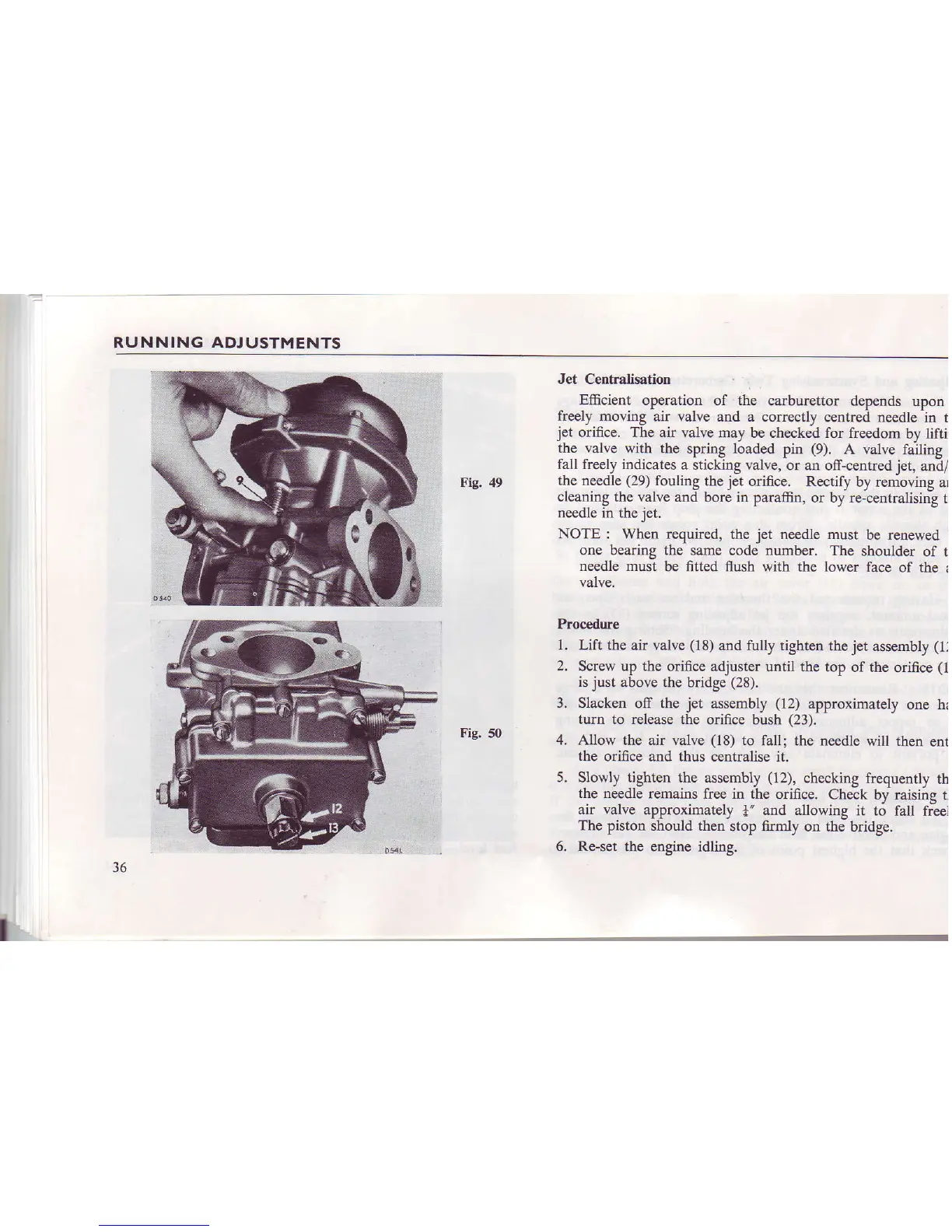

Fig.

50

Jet Centralisation

Efrcient

operation of the

carburettor depends

upon

freely moving

air valve and a correctly

cenhed needle

in t

jet

orifice. The air valve may

be checked for freedom

by

liftir

the

valve

\ ith

the spring loaded

pin

{9t.

A

valve

lailing

fall freely indicates

a srick-ing valre. or

an off-cenrred

jet.

an;/

the needie

(29)

fouling rhe

jit

orifice. Recrify

by renioving

ar

cleaning

the

valve

and bore in

paramn, or by re-centralising

tl

needle in the

jet,

NOTE : When required,

the

jet

needle must

be renewed I

one bearing the same

code number. The

shoulder of t

needle musi

be fitted flush with the lower

face

of the z

valve.

Procedure

l. Lift the

air

valve

(18)

and fully tighten

thejet assembly

(1:

2.

Screw up the

orifice adjuster until the

top of the

orifice

(1

is

just

above the bddge

(28).

3. Slacken

off the

jet

assembly

(12)

approximately

one hi

turn to release the

orifice bush

(23).

4. Allow the air valve

(18)

to fallt the needle

will then

ent

the

orifice and thus centralise

it,

5. Slowly lighlen the

assembly

(12).

checking

frequently

rh

rhe niedle remains

free in the

orifice. Cheik

biraisiie rl

air valve approximately

+"

and allowing

it t6

fal fiee]

The piston should then

stop furr y on the

bridge.

6. Re-set the

engine idling.

l6

Loading...

Loading...