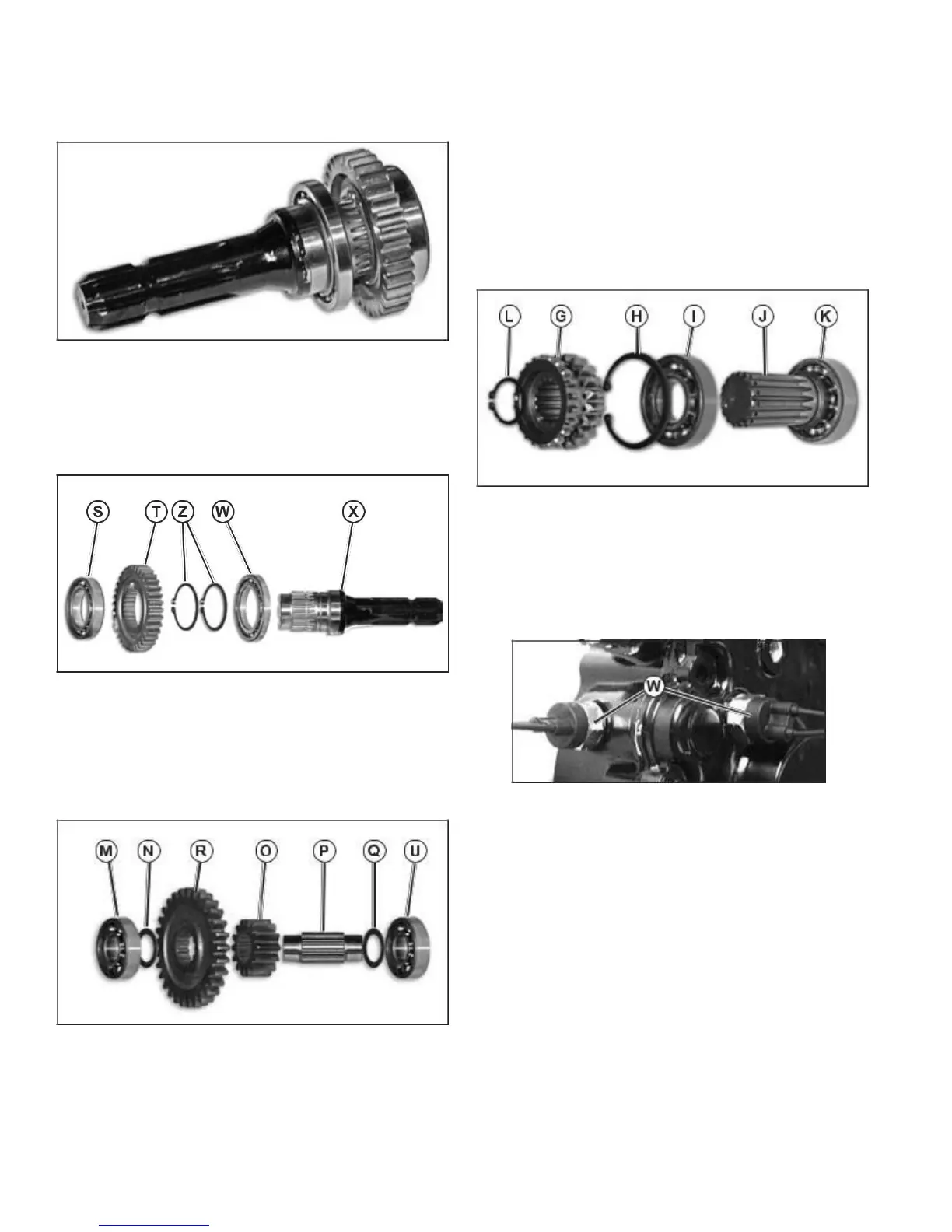

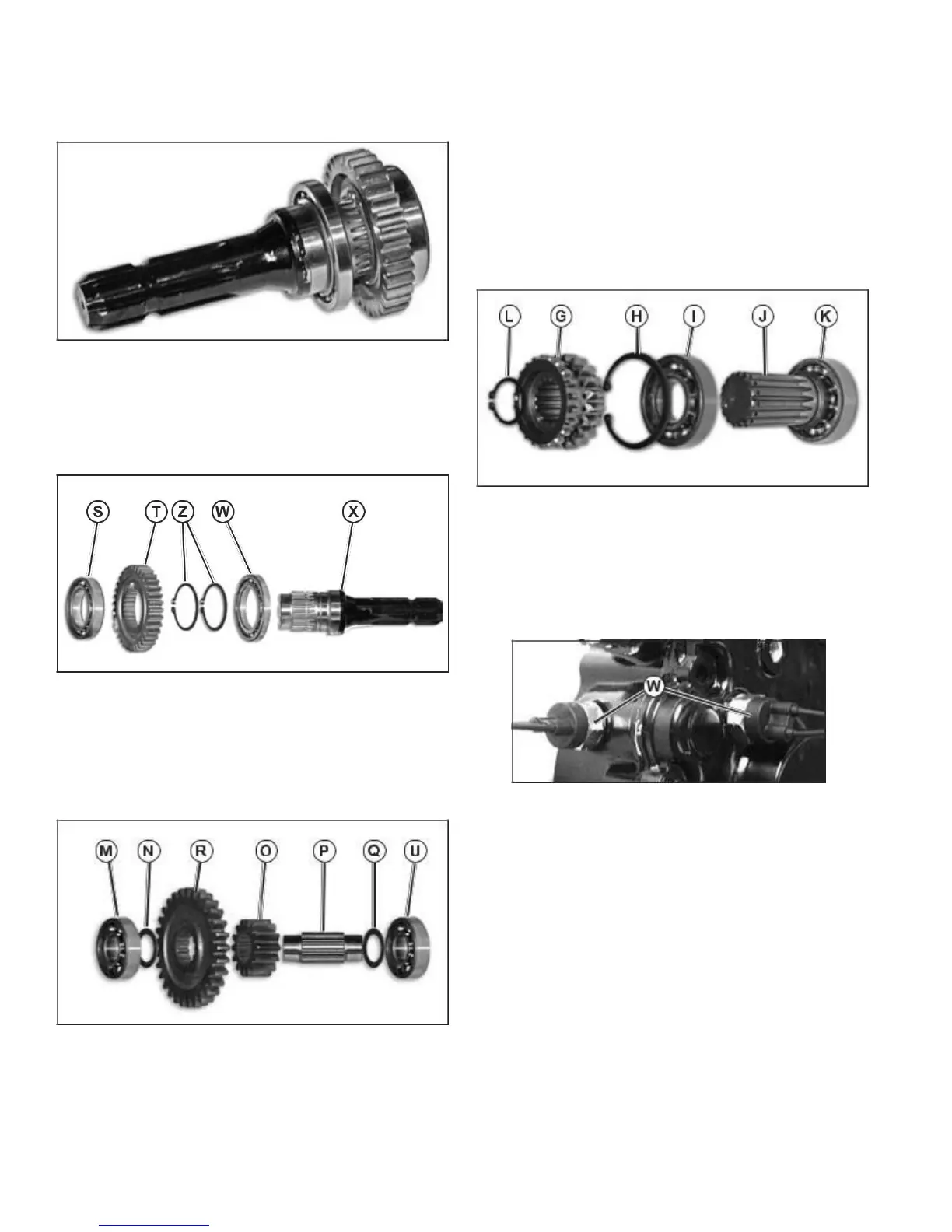

Rear PTO Removal and Installation (continued)

Fig. 32, Rear PTO Shaft Assembly

11. Remove press bearing (S) from the PTO shaft (X); then,

remove PTO gear (T), snap rings (Z), and press bearing

(W) from PTO shaft. Inspect all components for

wear or damage, replace as necessary. (Fig. 33)

Fig. 33, Rear PTO Shaft Disassembly

12. Remove press bearing (M) from idler shaft (P). Remove

washer (N), PTO input gear (R), and idler pinion gear (O).

Remove press bearing (U) and remove washer (Q) from

idler shaft (P). Inspect all components for wear or dam-age,

replace as necessary. (Fig. 34)

Fig. 34, Rear PTO Pinion/Input Gear Disassembly

NOTE: If rear PTO input gear (R), see fig. 34, replacement is

necessary, the shift collar (F), see fig. 36, and rear PTO idler

gear (G), see fig. 35, must be replaced also. The three gears are

available as a set. Rear PTO gear (T), see fig. 33, and rear PTO

idler pinion (O), see fig. 34, must be replaced as a set.

13. Remove snap ring (L), idler gear (G), snap ring (H),

press bearing (I), and press bearing (K) from shaft

(J). Inspect all components for wear or damage,

replace as neces-sary. (Fig. 35)

NOTE: Recall writing/numbers on all outer bearing

races, and install bearings in reverse order as removal.

Fig. 35, Rear PTO Idler Gear Disassembly

14. If necessary, remove ball switch (W) and O-ring.

(Fig. 36)

• If removed, install O-rings and ball switches (W). DO

NOT overtighten. Tighten to 34 N•m (25 lb-ft).

Fig. 36, Ball Switches

15. Inspect all parts and replace as necessary.

Assembly is reverse order of disassembly.

16

Loading...

Loading...