Hydrostatic Pump Inspection (continued)

A - Washers

B - Piston Spring (7 used)

C - Snap Ring

D - Cylinder Block

E - Washer

F - Spring

G - Piston (7 used)

H - Thick Thrust Plate

I - Thrust Bearing

J - Thin Thrust Plate

IMPORTANT: Avoid damage! Keep pistons matched

with bore of cylinder block. Do not interchange motor

pistons and valve plate with pump pistons and valve

plate. Pistons and cylinder blocks are a matched set.

1. Spring is compressed. Apply an external force to

com-press spring farther before removing snap

ring. Then slowly remove external force.

2. Remove parts from transaxle as necessary.

NOTE: Pump rotating components must be replaced

as a set. Thin thrust plate must be replaced as a set

with the pump swash plate and bushing.

3. Check cylinder block for grooves, scoring,

discoloration or pitting.

NOTE: Scoring is fine scratches or grooves cut into the highly

machined surface. When the scratches can be detected by feel

using a lead pencil or fingernail, the part must be replaced.

4. Check for free movement of pistons in cylinder bores.

5. Check pistons for flat areas, scoring or

discoloration. Thrust bearing must rotate freely.

For inspection of pump valve plate, refer to “Center

Valve Block Disassembly and Assembly:” on page 33.

Transaxle Disassembly

1. Remove control arm damper. (See “Control Arm

and Damper Removal and Installation” on page 1.)

2. Remove hydrostatic transmission and pump. (See “Hy-

drostatic Transmission 2WD and 4WD” on page 35.)

3. Remove axle housings. (See “Rear Axle Assembly Re-

moval and Installation” on page 41, and See “Rear Axle

Assembly - Disassembly and Assembly” on page 42.)

4. Remove brakes. (See “Brakes Removal and

Installation” page 43.)

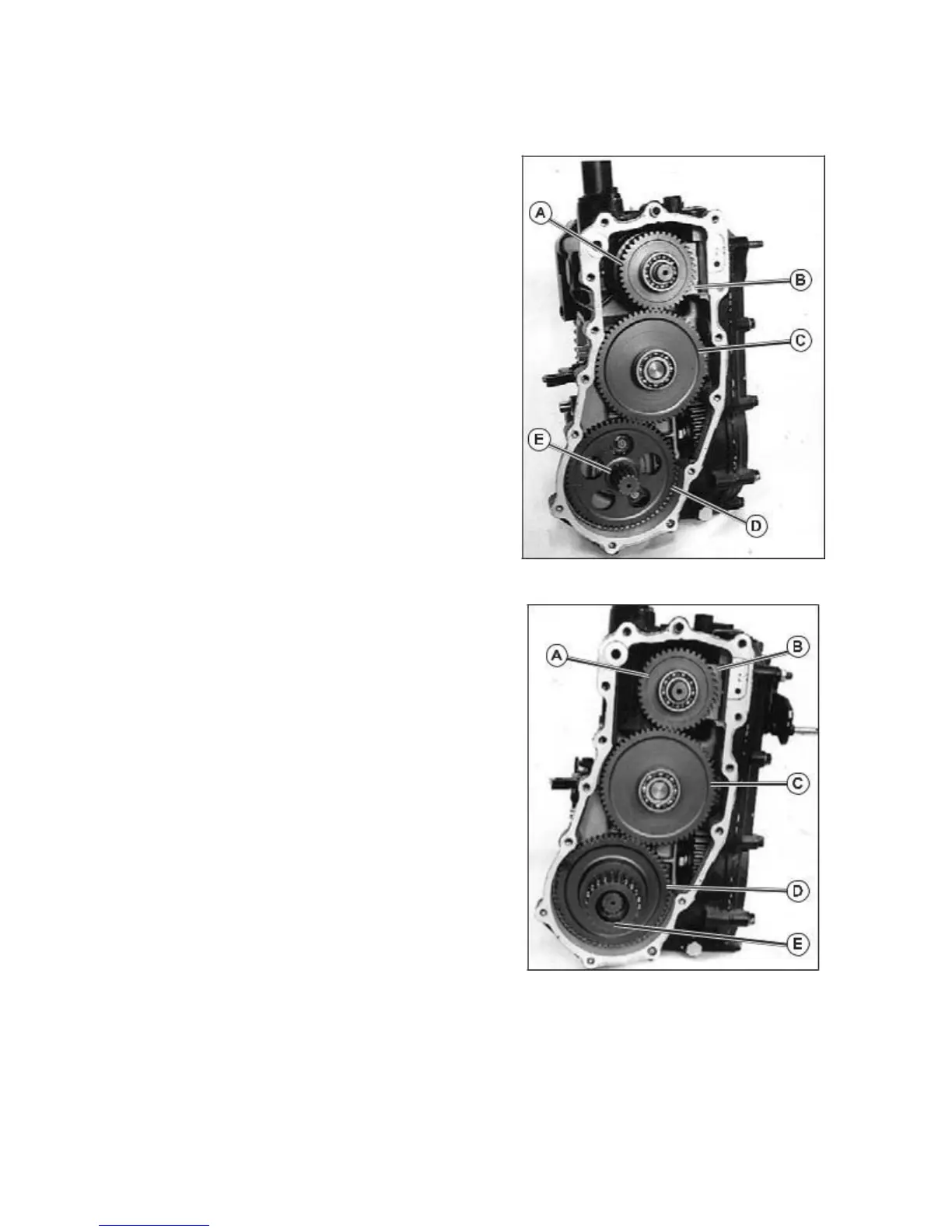

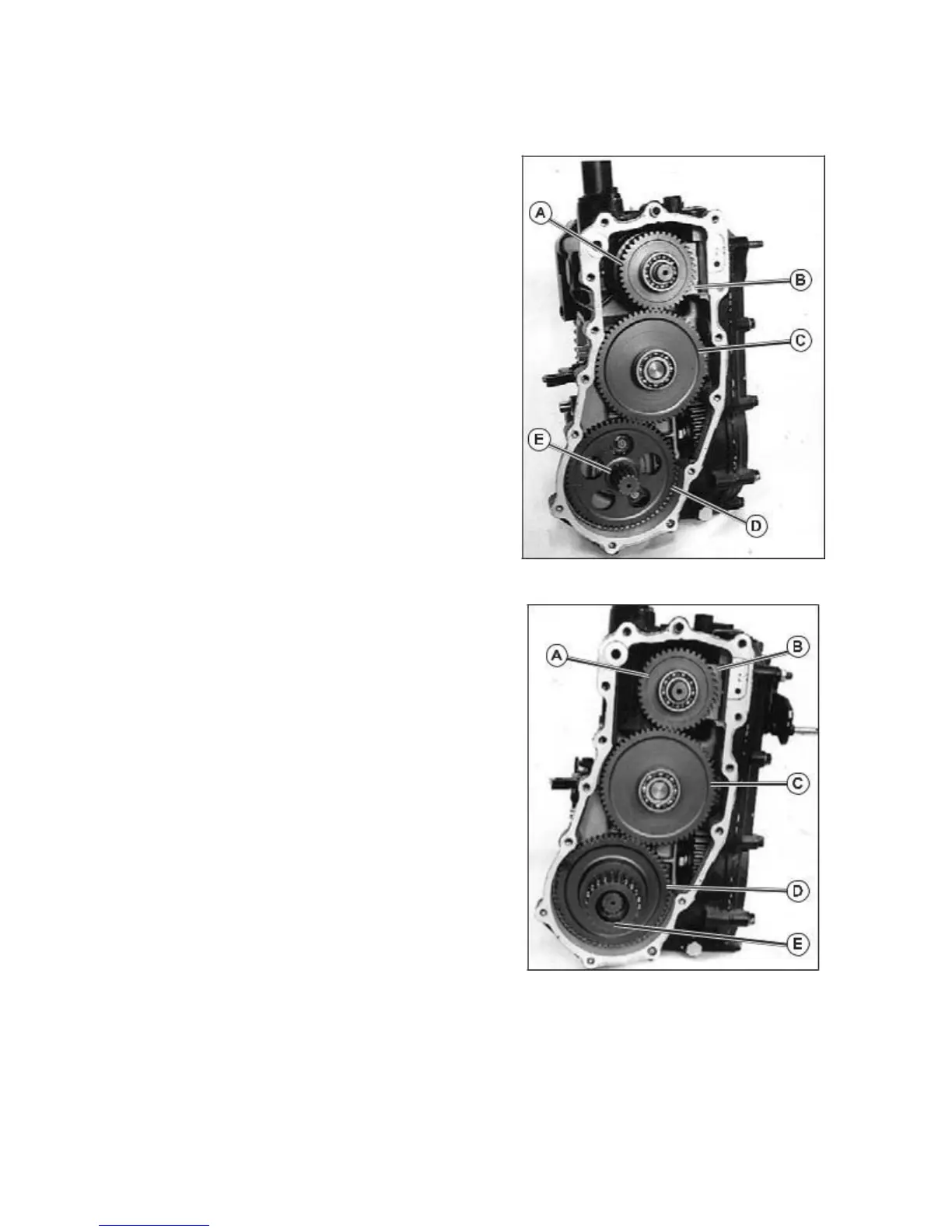

5. Remove PTO idler shaft assembly (C), snap ring

(E), PTO gear (D) (or rear drive gear set).

Fig. 61, Without Rear PTO Option

Fig. 62, With Rear PTO Option

6. Remove PTO brake shoe (B) and clutch (A). (See

“PTO Brake Removal and Installation” on page 6.)

7. Remove large snap ring (H) and input shaft assembly.

8. Remove large snap ring (L), small snap rings (G and K)

washers (M and J), and ball bearing (I) from input shaft

(F). (Fig. 63)

36

Loading...

Loading...