22

Manual 4804 Rev C p/n 004804 0000

08

REASSEMBLY

GENERAL

All pans must be clean. Clean off old sealant ¿ lm

at housing interfaces and remove with an effective

solvent. All joint and impeller faces must be free of

any nicks.

OTE: N

• Standard cast-iron construction

FA and BA pump housing joints

are sealed with Loctite Corp./

Permatex Aviation Form - A - gasket

liquid sealant 3H, thinning solvent

Denatured Alcohol.

• Stainless steel pumps CD3 are

assembled with PTFE glass-¿ lled

gaskets in lieu of sealant. Note: Iron

pumps designated for hot operation

(220°F [104°C] limit) are assembled

with paper shims and gasket liquid

sealant 3H.

• Sealant (when used) must be applied

lightly on one surface of joint with

a small stiff brush. The sealant can

must be capped when not in use to

avoid solvent evaporation. If needed,

use listed thinner to maintain original

À uid consistency.

• Assembly should proceed without

interruption until tie-rods for the

pump are half-tightened to prevent

early setting of sealant.

• The following torque values (ft-lbs)

apply for fasteners. Always replace

the end plate screws. Use new

stainless steel cap screws with nylon

locking inserts. DO NOT REUSE THE

OLD SCREWS.

• For installation with multiple pumps

and in-house repair, it is helpful to

have cast-iron dummy bearings

with outside diameter 0.001" smaller

than, inside diameter 0.001" larger

than, and width equal to the NDE ball

bearing.

• Ball bearings for pump models -HT

(as shown on the nameplate) prior

to August 1998 are lubricated with

special high-temperature grease and

are etched on the outside diameter

“Spec. lube.” They should not be

replaced with standard bearings.

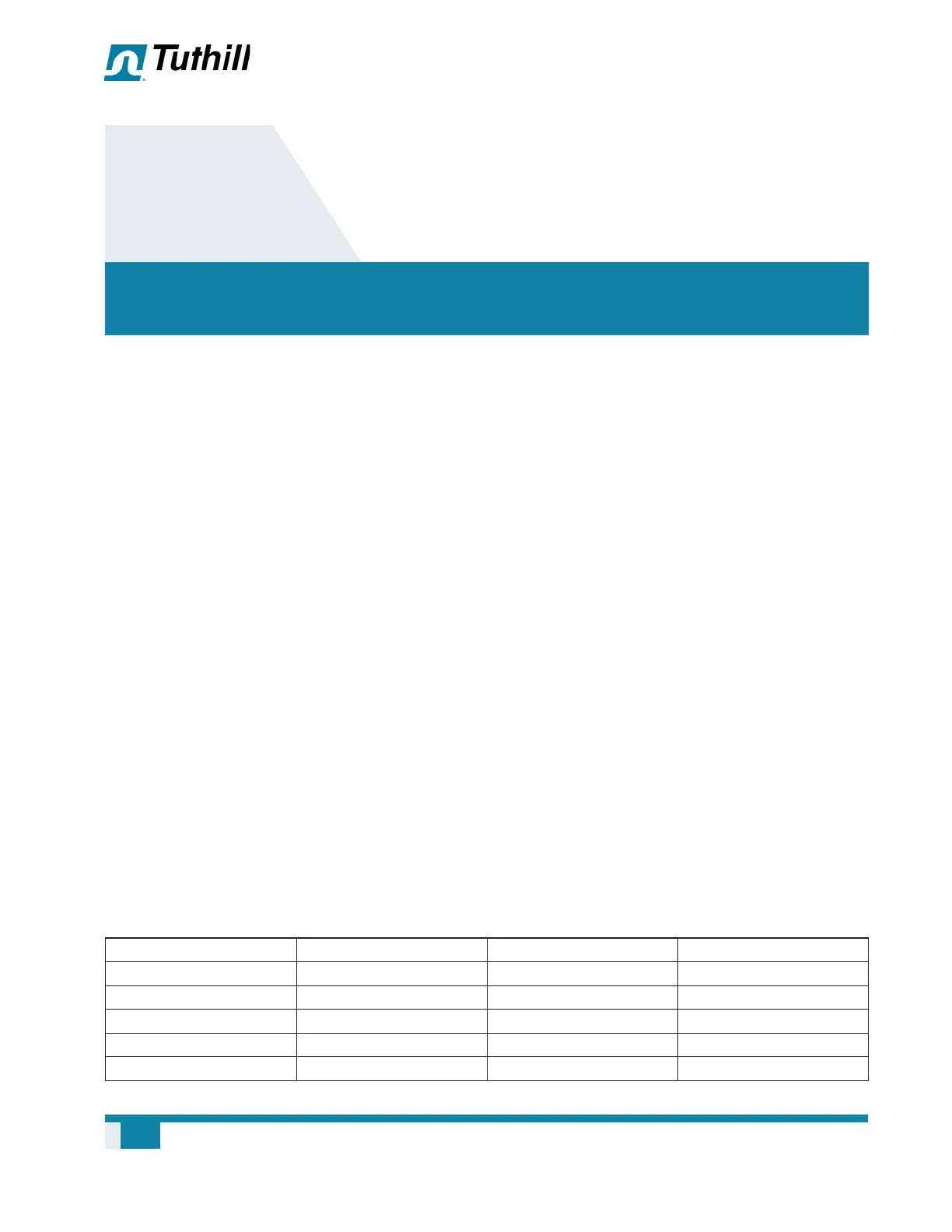

Table 8-1

Pump Model End Plate Screws Tie-Rod Nuts BRG HSG Screws

40/75 20-25 40-45 25-30

125 15-20 40-45 25-30

200/300 20-25 40-45 30-35

525 25-30 60-65 40-45

950 25-30 70-75 40-45

Loading...

Loading...