nextec™ — Predicts. Protects. Performs.

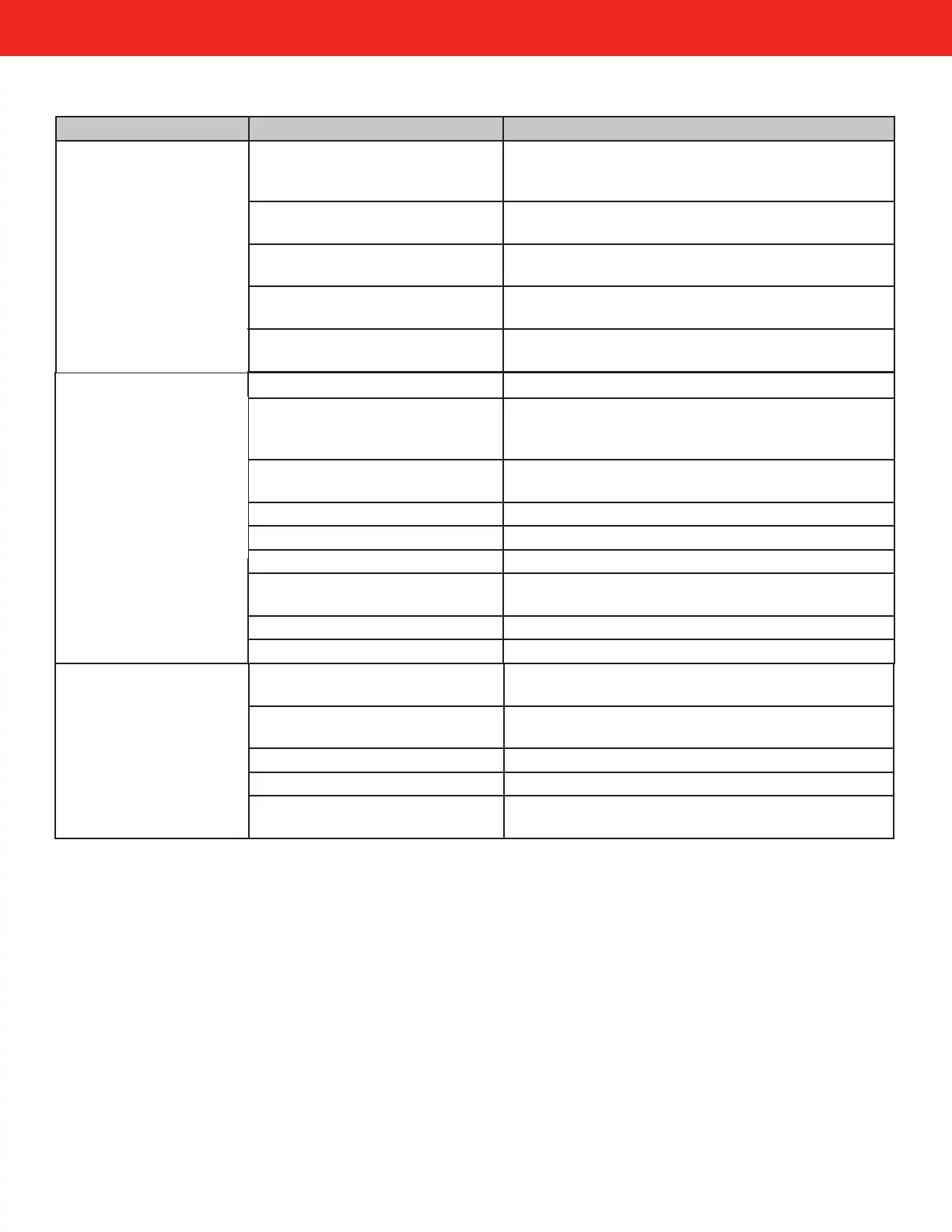

Troubleshooting (cont’d)

Motor stalls / fuse blows. Short in wiring. Inspect electrical cable for shorts and replace as

necessary.

Excess rotor or vane wear. Check vanes for nicks, damage, obstructions, or

excess wear. Replace as necessary.

Pump rotor lock-up. Clean and inspect rotor and vanes.

Debris in pump cavity. Clean debris from pump cavity.

Components rusting from pumping

water.

Let pump dry completely.

Low capacity. Excessive dirt in screen. Remove and clean screen.

Suction line problem. Check suction line for leaks or restrictions; it may be

too small in diameter, too long, not air tight, or too low

vertically.

Excessive rotor, vane, rotor cover,

or housing wear.

Inspect rotor, vanes, rotor cover, and housing for

excess wear; replace as necessary.

Hose or nozzle damage. Replace hose or nozzle.

Low uid level. Rell tank.

Pump runs slowly. Incorrect voltage. Check incoming line voltage while pump is running.

Vanes sticking. Check vanes for nicks, damage, obstructions, or

excess wear. Replace as necessary.

Wiring problem. Check for loose connections.

Motor problem. Return to place of purchase.

Bold text indicates repairs that are not serviceable by the owner; pump must be returned to the place of purchase for repairs.

*This condition will shut the motor off.

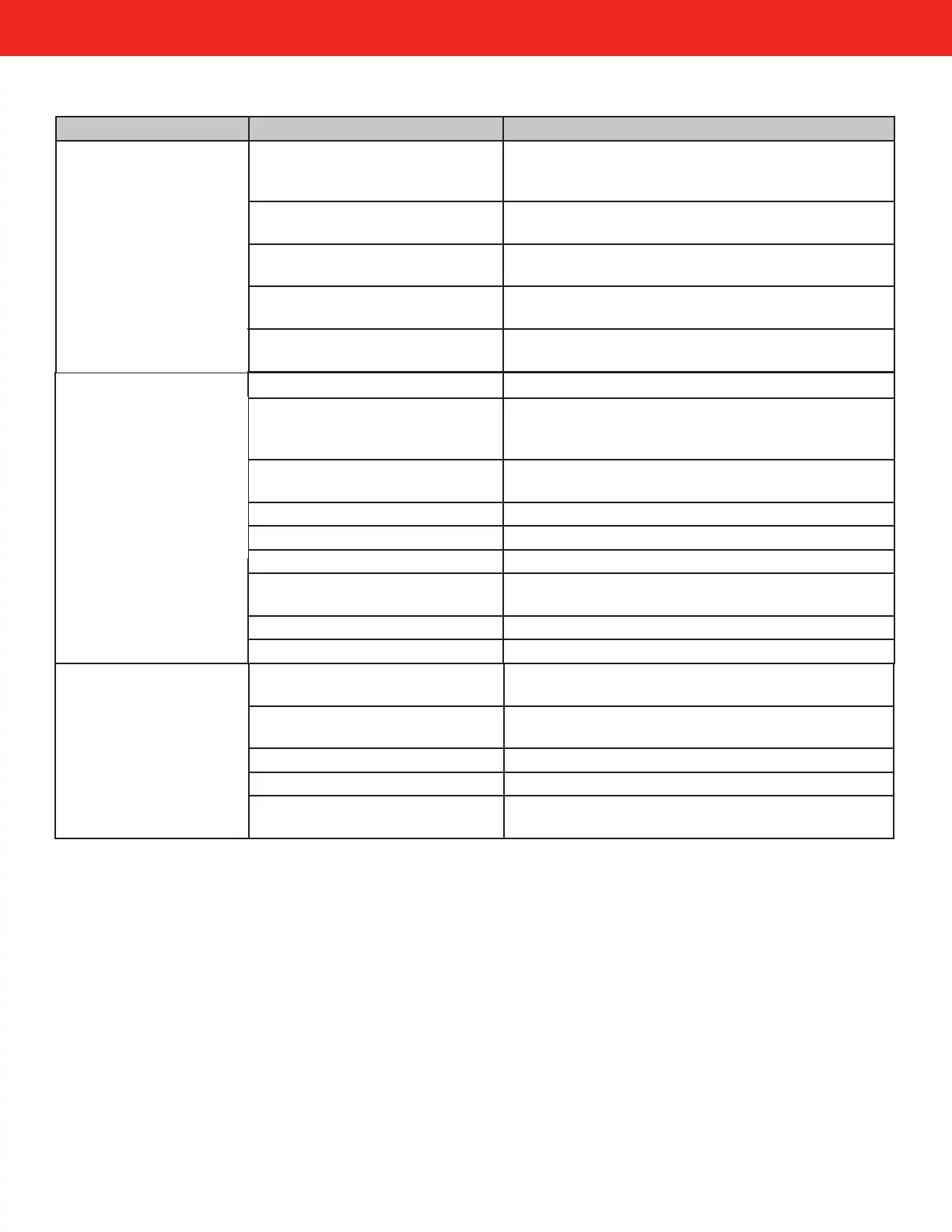

Symptom Cause Cure

Pump won’t prime. Suction line problem. Check suction line for leaks or restrictions; it may be

too small in diameter, too long, not air tight, or too low

vertically.

Vanes sticking. Check vanes for nicks, damage, obstructions, or

excess wear. Replace as necessary.

Excessive rotor, vane, rotor cover,

or housing wear.

Inspect rotor, vanes, rotor cover, and housing for

excess wear; replace as necessary.

Inlet / Outlet blocked. Check pump, hose, nozzle, and lter / strainer for

blockage.

Excessive vertical or horizontal

inlet plumbing

Reduce vertical or horizontal distance from pump to

liquid.

Loading...

Loading...