33

6.4 Loading and Unloading the Device

6.4.1 Safety

Protective equipment, clothes and other safety instructions should

be implemented

in accordance with local and national regulations

and/or rules!

For proper sterilization - Do not overload the chamber. Only

autoclavable products shall be used; please refer to the material or

instrument manufacturer's instructions for sterilization of unknown

materials or instruments.

6.4.2 Loading

Correct loading of the autoclave is essential to successful

sterilizing for

several reasons. Efficient air removal from the

chamber and the load will permit steam penetration and saturation,

and allow proper drainage of condensate. Additionally, correct

loading will reduce damage to packs and their contents and

maximize efficient use of the sterilizer.

For detailed loading instructions, see sec. 7 (Preparation before

sterilization).

6.4.3 Unloading

On completion of the cycle, the load shall be immediately

removed from the sterilizer and a visual inspection made to

ascertain that the load is dry, and that sterilizing indicators have

made the required color change.

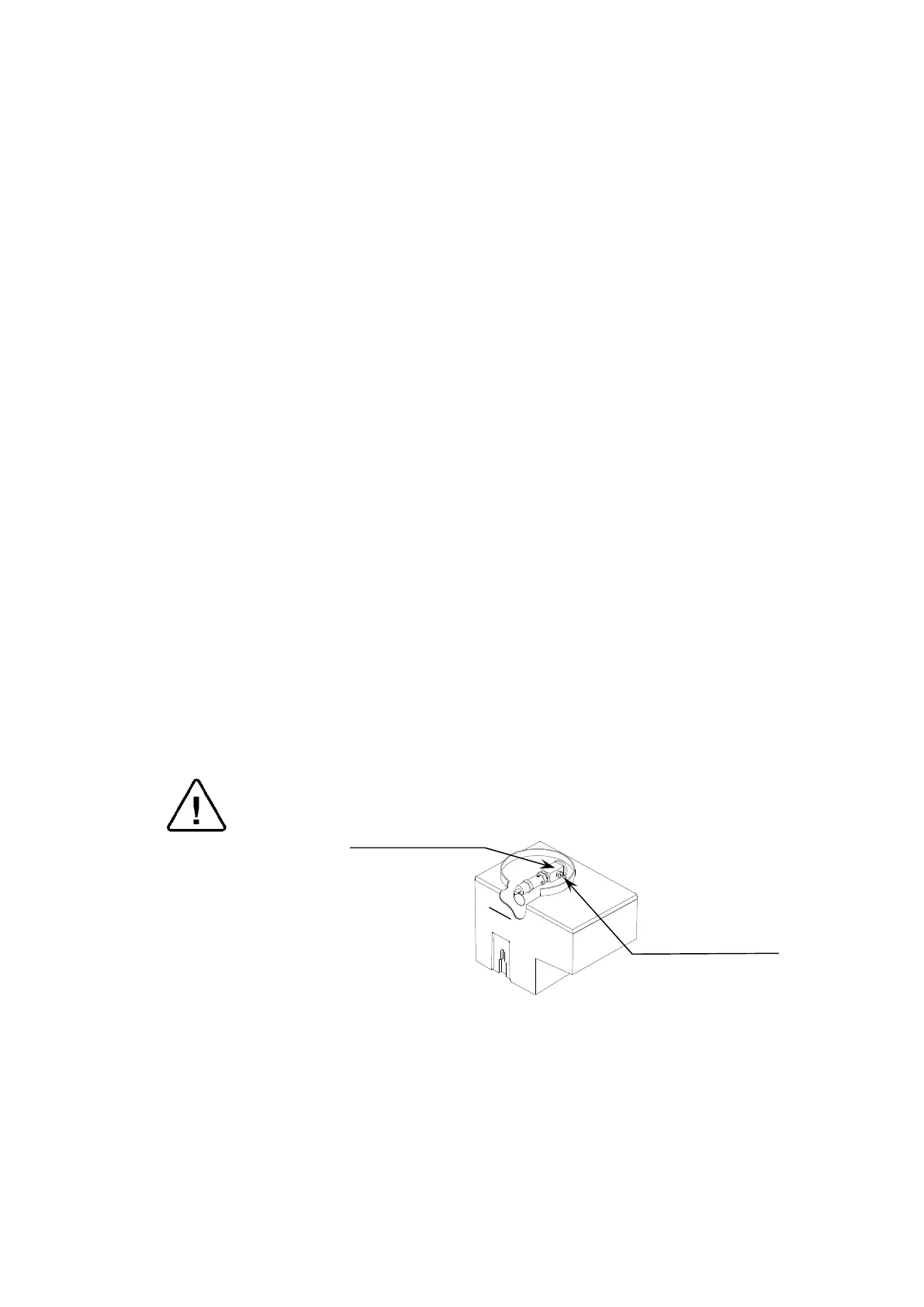

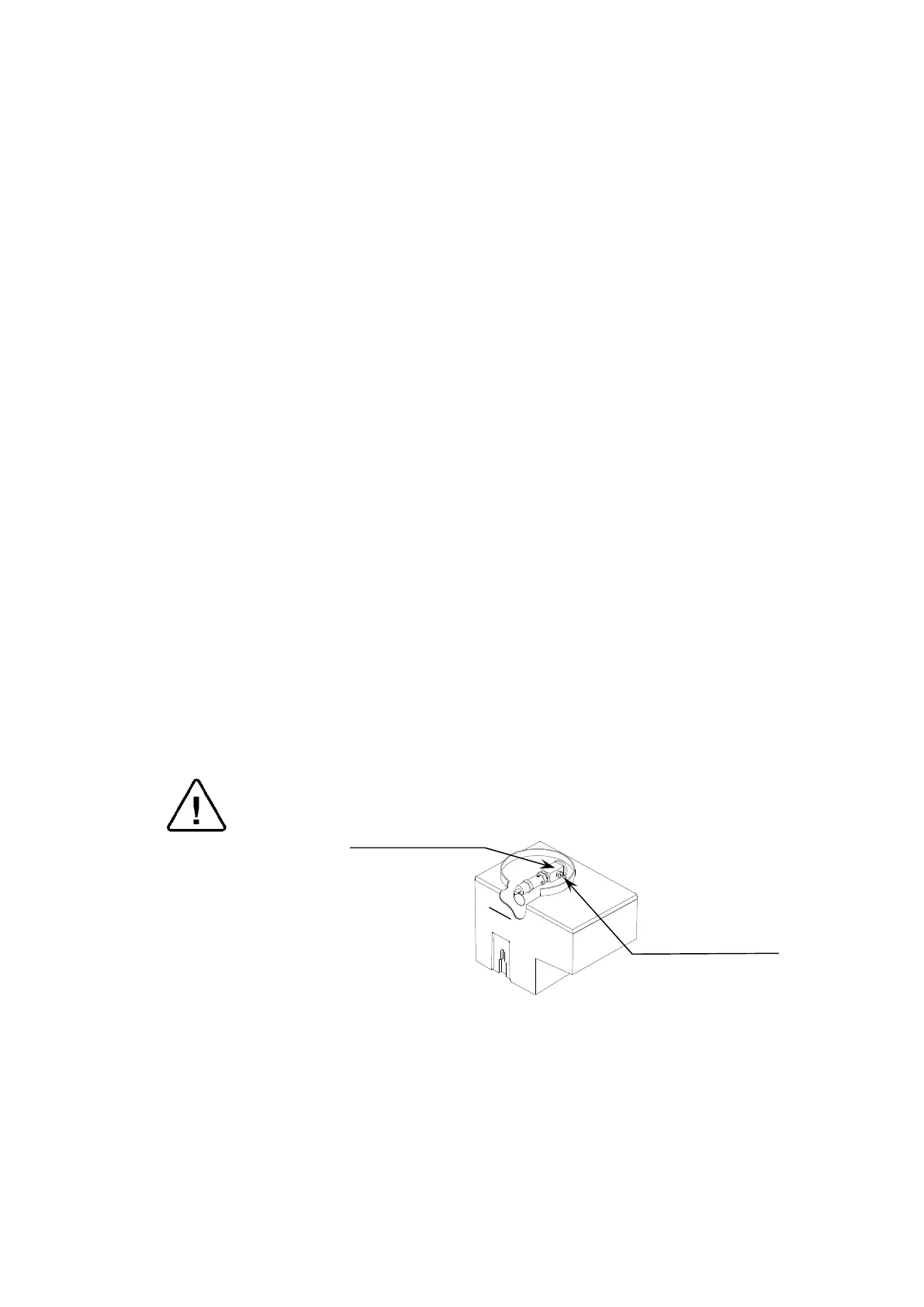

6.5 Filling the Water Reservoir

Remove the water reservoir cover. Pour distilled water into the reservoir

through the opening on top of the autoclave until it reaches the base of the

safety valve holder, approximately 0.7 gallons (3 liters).

Use water-having characteristics as per table in sec 2.11.

Caution:

Under no circumstance should water be filled above the safety valve

holder.

USE DISTILLED WATER ONLY. The impurities in tap water will

create the need for more frequent cleaning and maintenance, in addition,

they will accumulate and block the hole of the Air Jet. This will prevent

the temperature in the chamber from rising properly. This will cause the

unit to abort its cycle, spore tests to fail and indicator strips not to

change color. It is essential from time to time during heating and

sterilization phases that a spray of steam should escape, from the Air Jet,

causing a hissing sound. If no escaping steam is evident or no hissing sound

heard, follow the instructions in sec 9.4 for cleaning the Air Jet.

SAFETY VALVE HOLDER

EXIT FOR STEAM SPRAY

Loading...

Loading...