13

Swiveltheouterguide(3)upwards.

Load label roll on the roll retainer in such a way that the labels can be inserted into the printhead in the right

position. The printing side of the labels must be visible from above.

Ensureapproximately4cmofmediaprotrudesoutoftheprinthead.

Pushtherolluntilitmakescontactwiththeinnerguide(3).

Swiveltheouterguide(3)downwardsontothemediahub(4).Therollmustbebrakedslightlybythetheguides

when supplying media. If necessary re-adjust symmetrically the guides.

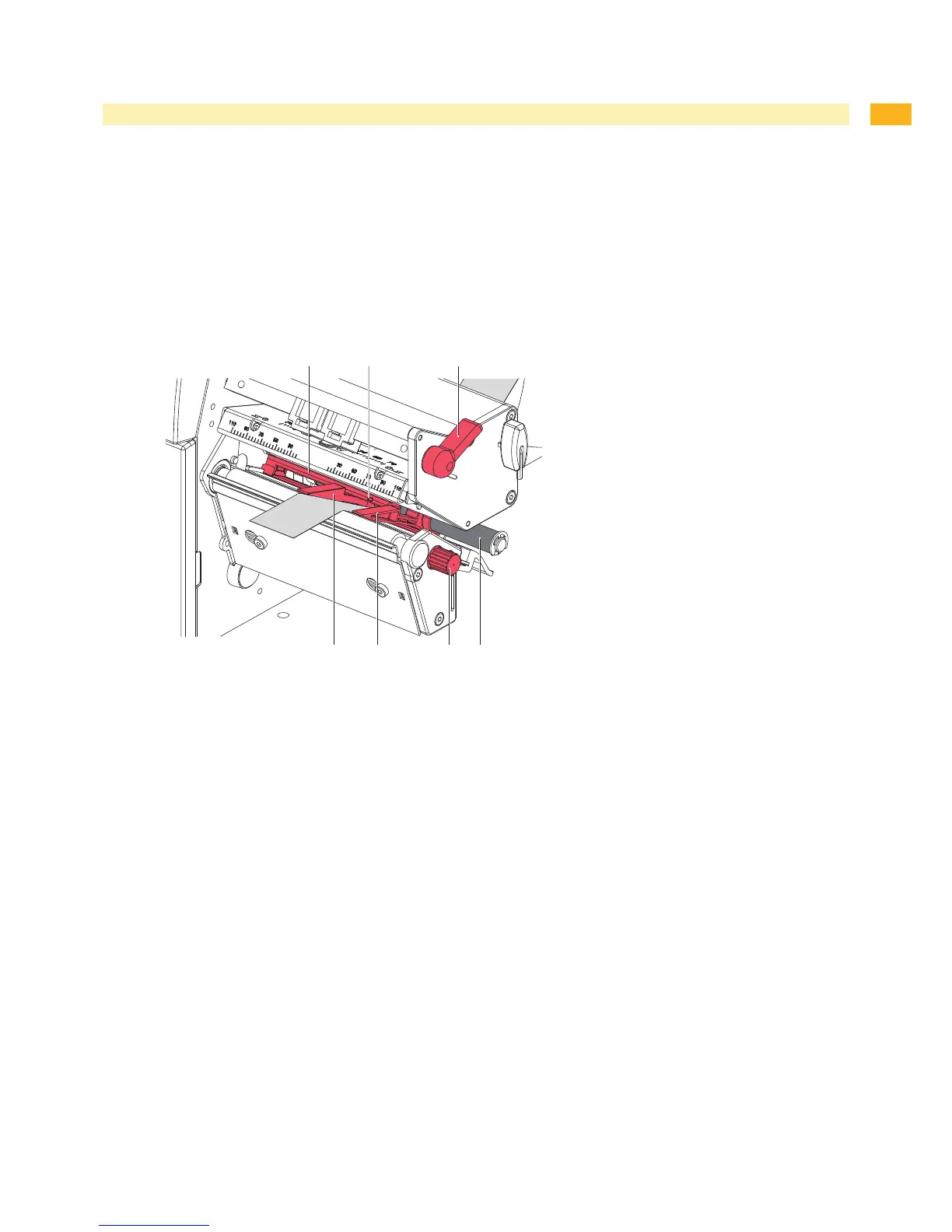

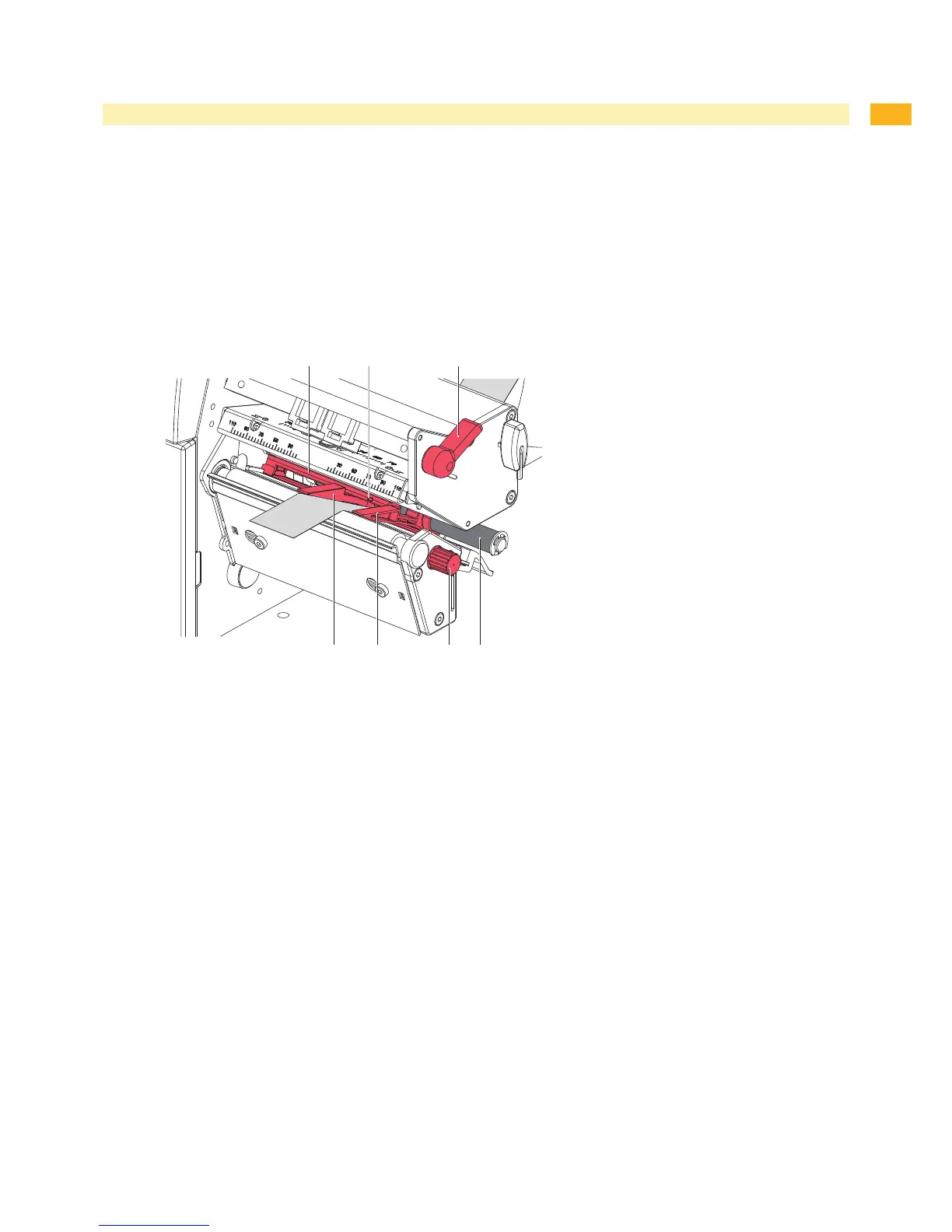

4.1.2 Inserting a Media Strip into the Printhead

Fig. 7 Inserting a Media Strip into the Printhead

Turnlever(10)counterclockwisetolifttheprinthead.

Moveguides(6)apartwiththeknob(9)untilthemediacanpassbetweenthem.

Pushmediastripbelowtheguideroller(5)betweentheguides(6).

Guidemediastripthroughthelabelsensor(7)insuchawaythatitleavestheprintmechanics(6)g2between

printhead(10)g2andtheprintroller.(11)g2

Moveguides(6)againsttheedgesofthematerialbyturningtheknob(9).

4.1.3 Setting the Label Sensor

Thelabelsensor(7)canbeshiftedperpendiculartothedirectionofpaperowforadaptationtothemedia.The

sensorunit(12)ofthelabelsensorisvisiblefromthefrontthroughtheprintunitandismarkedwithanindentationin

the label sensor retainer. When the printer is switched on, a yellow LED illuminates the sensor position.

Loosentheknurledknob(8)andpositionlabelsensorbymovingtheknurledknobinsuchawaythatthesensor

candetectthelabelgaporareexorcut-outmark.

- or, if the labels deviate from a rectangular shape, -

Alignlabelsensorwiththefrontedgeofthelabelinthedirectionofpaperow.

Turnlever(10)clockwisetolocktheprinthead.

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

4 Loading Material

Loading...

Loading...