44

Clogged nozzle

If there is no material flowing from the nozzle for at least 10 minutes it could suggest that there is some burnt material in

the nozzle, leading to a nozzle clog. In this case, the nozzle should be cleaned by performing the below described method.

Preparing

1. Remove the material from your Ultimaker by navigating to Material g Change. Select Cancel after you have removed

the material.

2. Place the print head in the front right corner to avoid bending of the XY axles when applying pressure to the material.

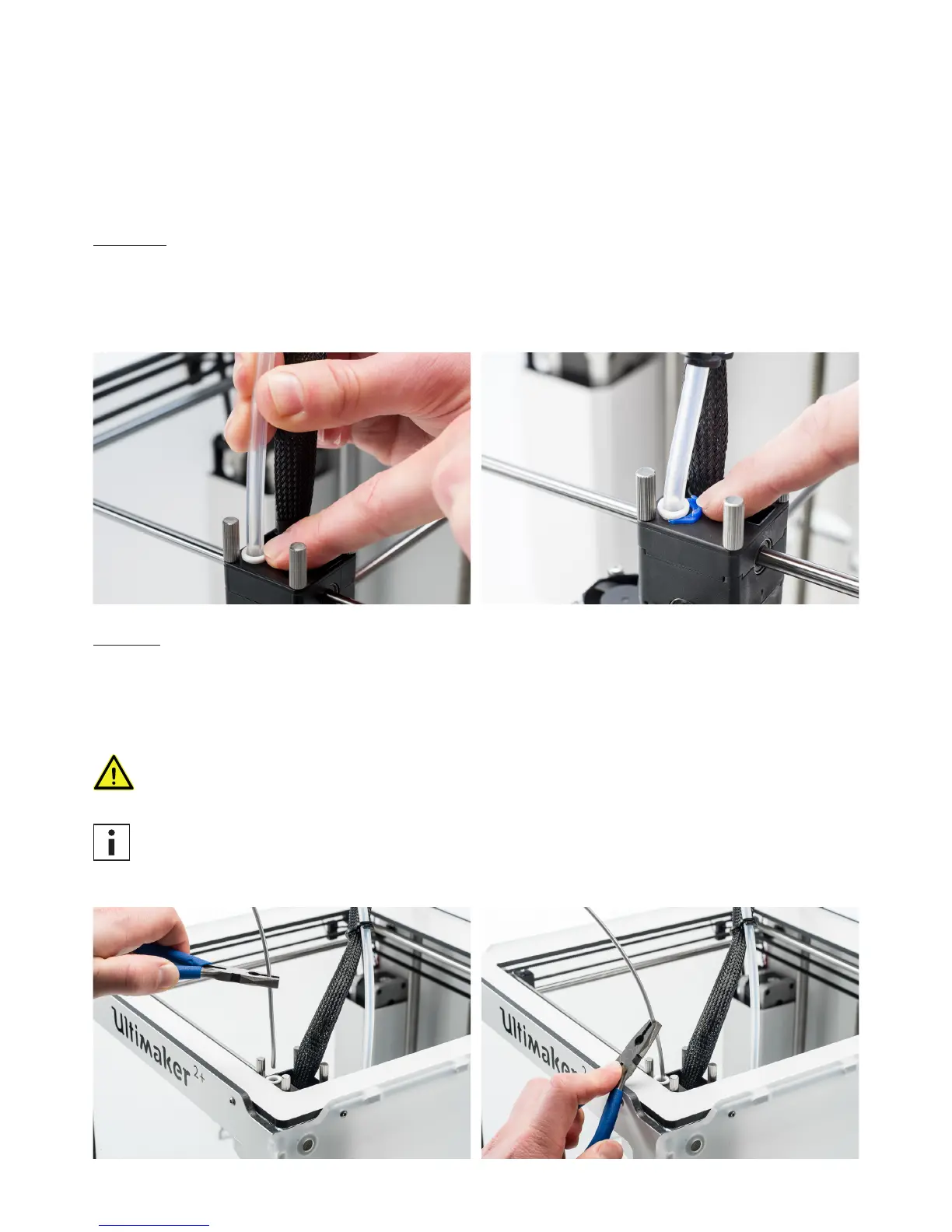

3. Remove the clamp clip from the top of the print head.

4. Remove the Bowden tube by pushing down on the tube coupling collet while pulling the Bowden tube upwards, out of

the print head.

Cold pull

1. Go to Maintenance g Advanced g Heatup nozzle and set the temperature to 260 °C.

2. Cut off approximately 20 cm of filament with a straight cut and try to straighten the material as much as possible.

3. When the nozzle reaches the target temperature of 260 °C insert the piece of filament into the print head until you feel

some resistance.

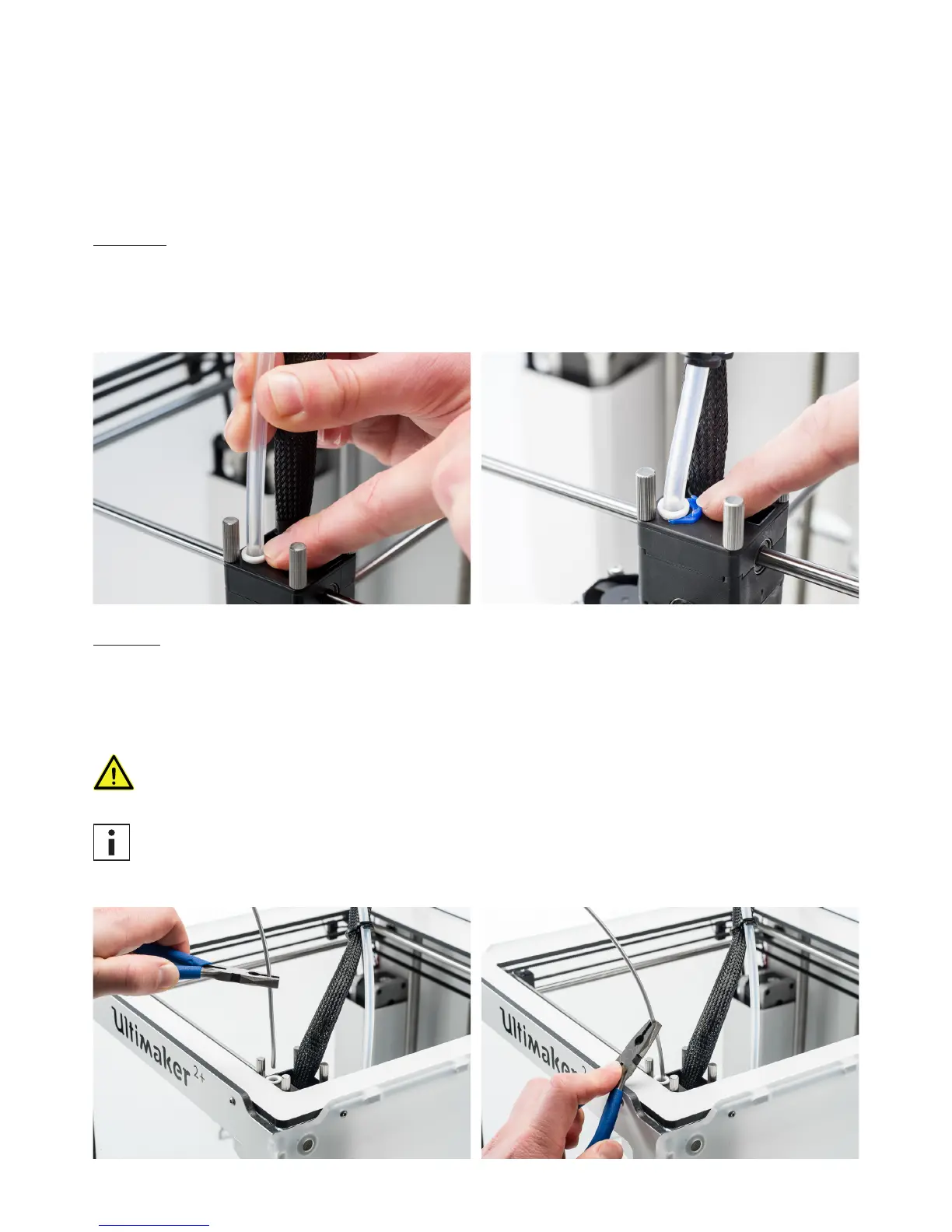

4. Hold the filament with pliers and gently apply pressure to extrude some material or until the filament cannot be

pushed any further.

The use of pliers is required to prevent injuries on your hands in case the material breaks.

5. Lower the temperature to 90 °C and maintain pressure on the filament until the nozzle reaches 150 °C.

The slight pressure on the material while cooling down is required to prevent air from entering the nozzle.

6. Release the filament and wait until the target temperature of 90 °C is reached.

7. Grab the filament with pliers and pull it out with a quick, firm pull.

Loading...

Loading...