PERIODIC INSPECTION

4-36

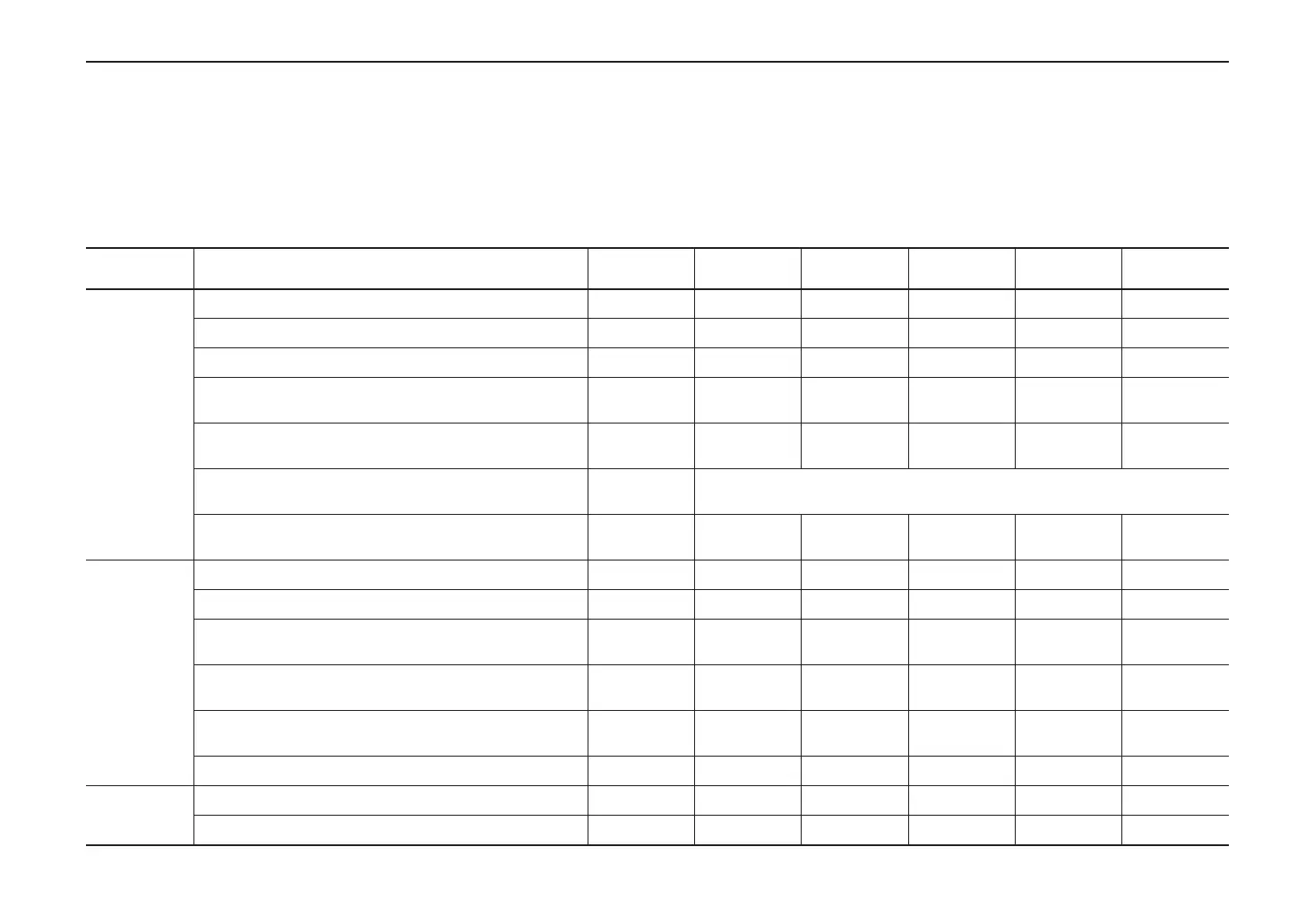

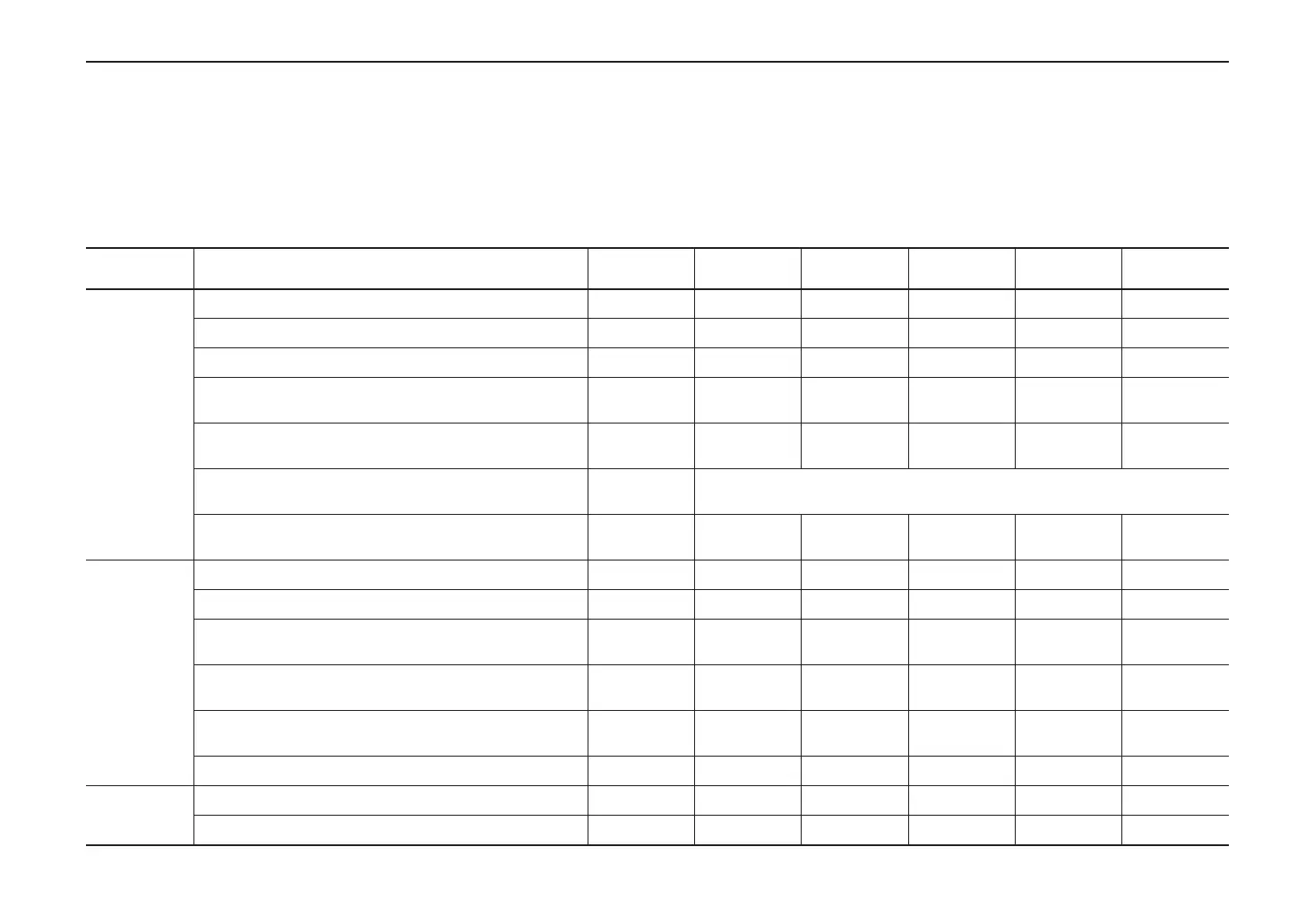

PREVENTIVE MAINTENANCE SCHEDULE

This maintenance schedule is worked out on the assumption that the lift truck will be used under typical working conditions. If the lift truck

is used under severer working conditions, earlier preventive maintenance is required. (The black dots in the table means “Change or

addition”.)

ENGINE

Checking

item

Service Required Tools Daily

Monthly

(200 hrs)

Trimonthly

(600 hrs)

Semiannually

(1200 hrs)

Annually

(2400 hrs)

Engine

Visually check for proper rotation. Visual

○ ○ ○ ○ ○

Check working noise. Auditory

○ ○ ○ ○ ○

Check exhaust gas (color). Visual

○ ○ ○ ○ ○

Check air cleaner element for contamination and clean, if

needed.

Visual

○ ○ ● ●

Check valve clearance.

Thickness

gauge

○

Retighten cylinder head bolts (No need to retighten except

when disassembling and reassembling cylinder).

Torque

wrench

Measure bolt torque and retighten if needed

(when disassembling and reassembling cylinder).

Check cylinder compression pressure.

Compression

gauge

○

Lubrication

system

Check for engine oil leaks. Visual

○ ○ ○ ○ ○

Check engine oil for level and contamination. Visual

○ ○ ○ ○ ○

Change engine oil. Operate

● (at initial 50

hrs)

● ● ●

Change engine oil lter element. Operate

● (at initial 50

hrs)

● ● ●

Drain oil through engine oil lter drain plug. Operate

○ (at initial 50

hrs)

○ ○ ○

Change water pump grease. Operate

●

Fuel system

Check fuel system for leaks (piping, pump and tank). Visual

○ ○ ○ ○ ○

Drain water from fuel lter. Operate

○ ○ ○ ○

Loading...

Loading...