Page 20

LPH800 TREATER

ROTATING DRUM

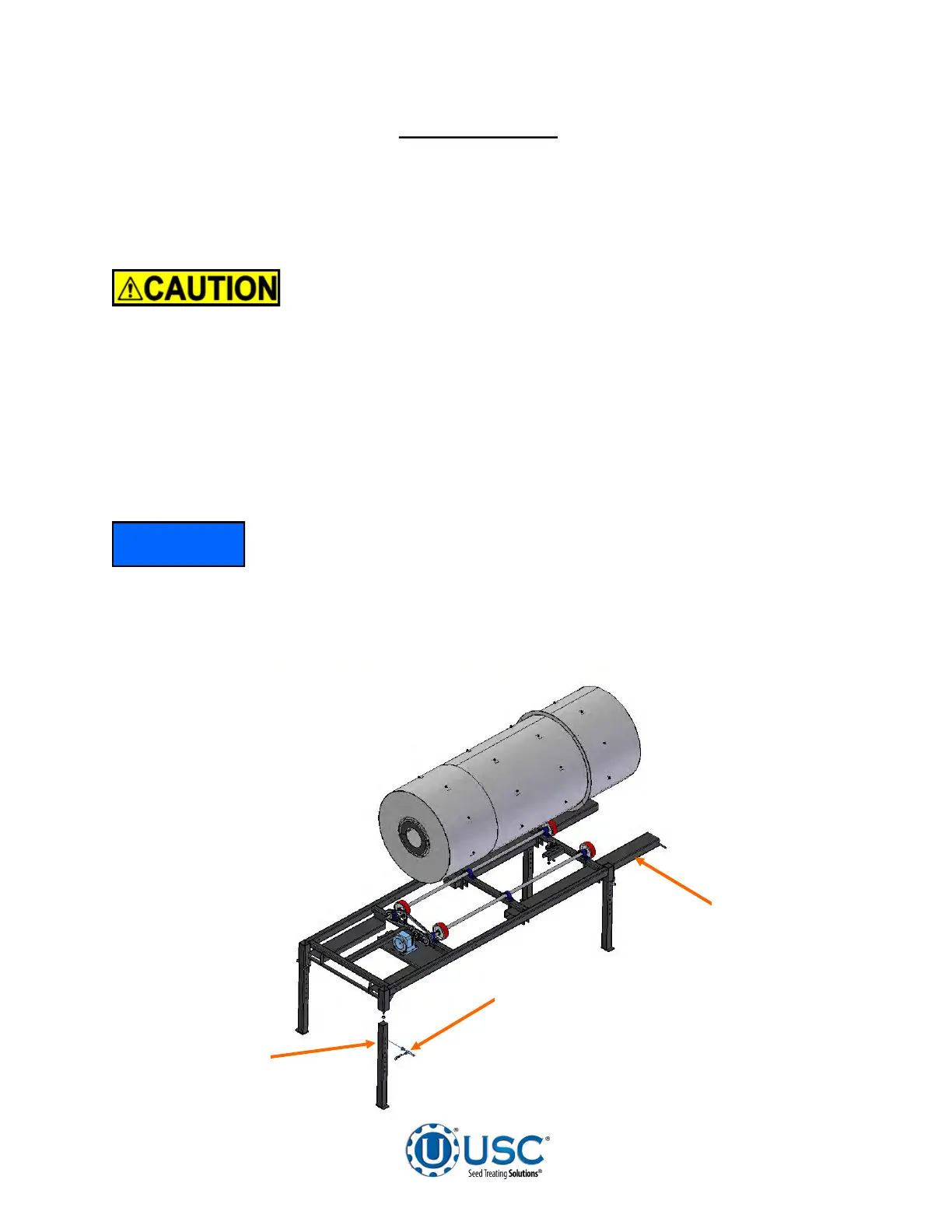

The rotating drum comes is six feet long and accepts treated seed through the opening

on the hopper end. As seed passes through the length of the drum it is tumbled,

producing accurate and uniform seed coating. The seed then exits the seed treater

out the discharge end of the machine.

Never allow exposure of persons or clothing to the drive shaft,

idler wheels, or the drum during operation. Always have the

safety shields in place during operation.

The time it takes for seed to move through the drum both during and at the end of the

run can be changed by lowering or raising the pins on the legs of the discharge end of

the treater. When the pins are in the same hole on all of the treater legs, the treater

has a natural downward tilt towards the discharge end of the treater. Lowering the pins

on the discharge end’s legs will give the treater more tilt during operation which will

allow seed to travel through the drum at a faster rate. Vice verse, raising those pins

will cause seed to stay in the drum longer.

It is not recommended to lower the discharge end’s pins more than

one hole setting different from the inlet end’s pins. If this is done,

a loss in seed coverage and chemical coating may occur.

The LPH800 Treater also comes standard with telescoping fork lift pockets. These

pockets can be slid out from underneath the treater to allow a fork lift to pick up the

treater from it’s discharge end.

Pin

Adjustable

Leg

Telescoping

Fork Pockets

NOTICE

Loading...

Loading...