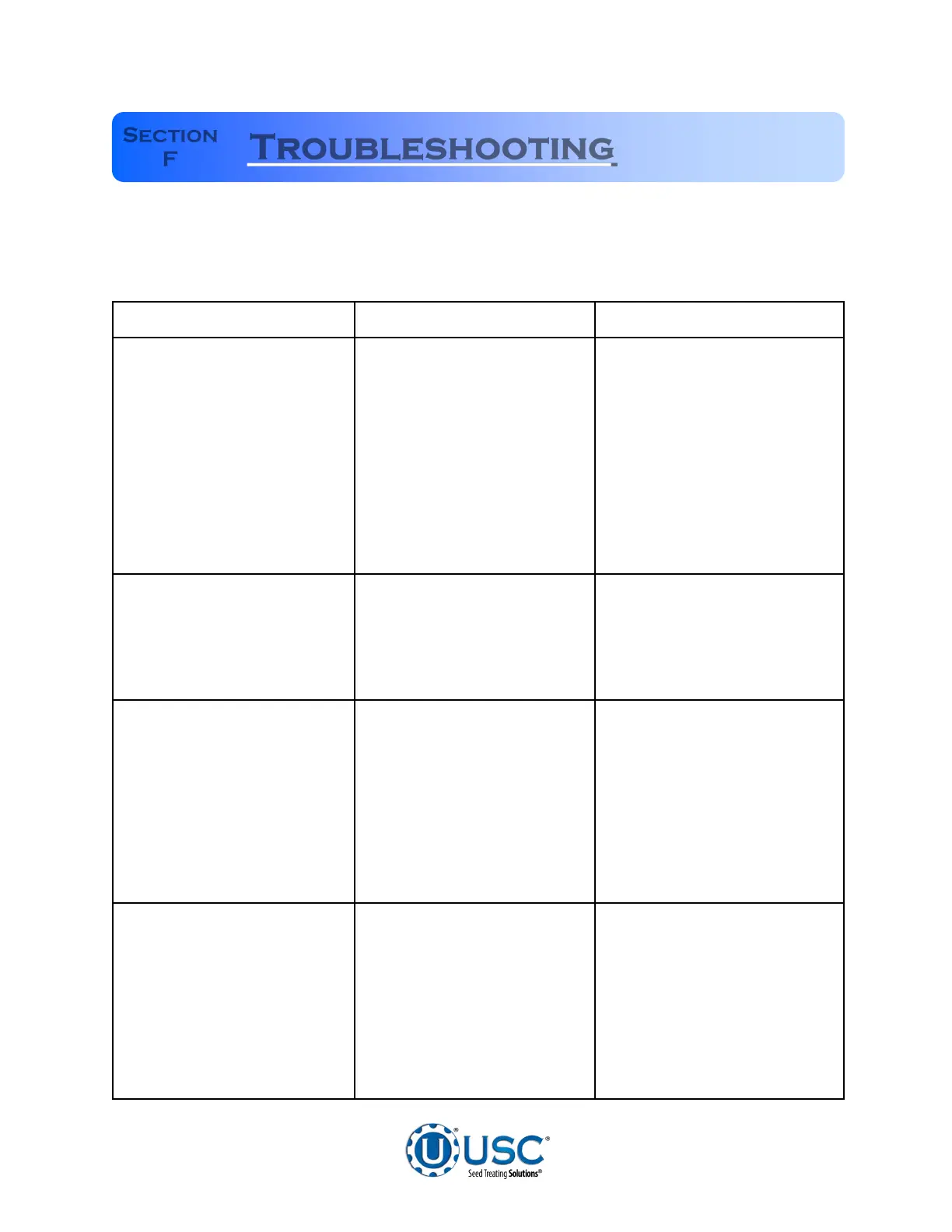

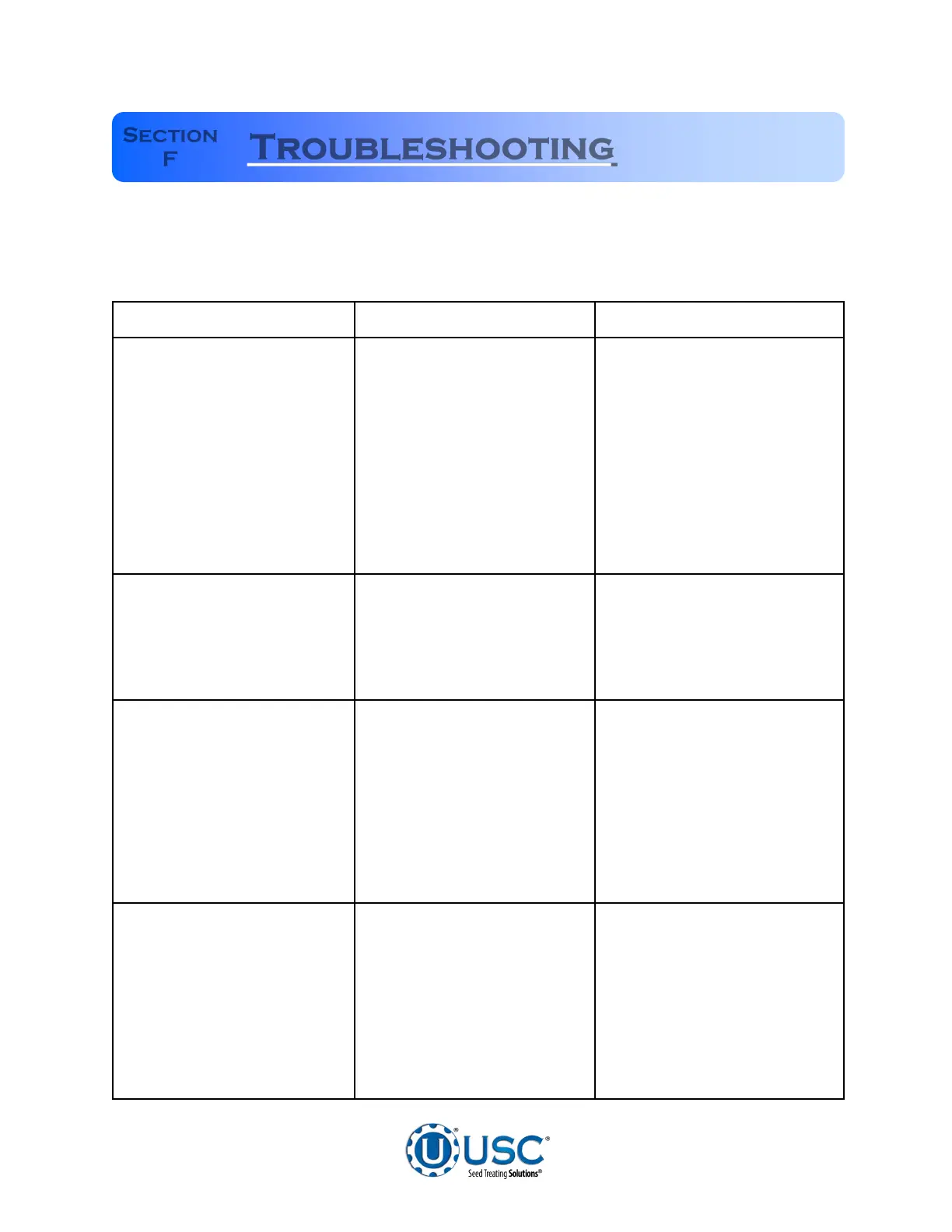

Page 40

LPH800 TREATER

Problem Possible Cause Solution

Inlet Conveyor will not turn on. 1. Inlet Conveyor proximity

switch is activated.

2. Inlet Conveyor proximity

switch is too sensitive.

3. Overload is tripped.

4. Conveyor is plugged into

wrong outlet on seed treater

panel.

1. Clean proximity switch

2. Adjust the inlet conveyor

proximity switch sensitivity by

turning the adjustment screw

counter-clockwise (page 42).

3. Reset Inlet Conveyor

Overload.

4. Check to make sure the inlet

conveyor is plugged into the

inlet conveyor receptacle.

Pump will not turn off in AUTO

when seed runs out.

1. Proximity switch is dirty.

2. Proximity switch is set too

sensitive.

1. Clean proximity switch.

2. Adjust the pump proximity

switch sensitivity by turning

adjustment screw counter-

clockwise (page 42).

Pump will not turn on in AUTO 1. Proximity switch is not

staying covered.

2. Atomizer is not on.

3. Proximity switch is not sen-

sitive enough.

1. Make sure Proximity Switch is

staying covered with seed

2. Turn on Atomizer. Atomizer

must be on to run pump #1

and #2 in Auto.

3. Adjust pump proximity switch

sensitivity by turning the

adjustment screw clockwise

(page 42).

Inlet conveyor won’t shut off

when hopper is full.

1. Seed is not hitting proximity

switch.

2. Proximity switch is not set

sensitive enough.

3. Inlet Conveyor is plugged

into wrong receptacle.

1. Make sure seed is hitting

proximity switch.

2. Adjust the inlet conveyor

proximity switch by turning the

adjustment screw clockwise

(page 42).

3. Make sure Inlet Conveyor is

plugged inlet conveyor

receptacle.

Troubleshooting

Section

F

Below is a table describing the most frequent problems and solutions with the LPH800

Seed Treater. For further assistance, contact USC at (785) 431-7900.

Loading...

Loading...