CONNECT GAS SERCONNECT GAS SER

CONNECT GAS SERCONNECT GAS SER

CONNECT GAS SER

VICEVICE

VICEVICE

VICE

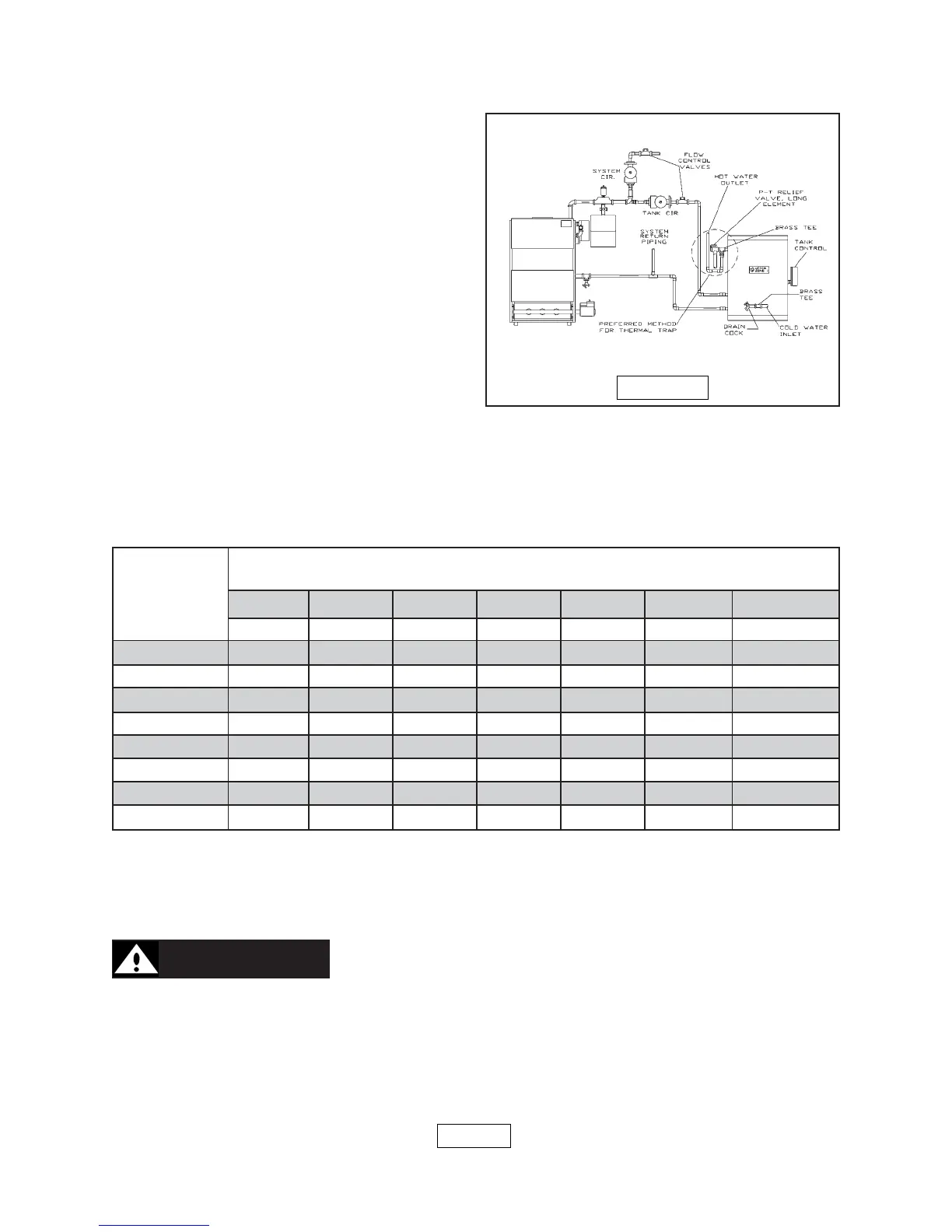

Connect gas service meter to control

assembly in accordance with the latest

revision of ANSI Z223.1 and local codes or

utility. A ground joint union should be installed

for easy removal of gas control for servicing.

A drip or trap must be installed at the bottom

of a vertical section of piping at the inlet to the

boiler. A pipe compound resistant to the

action of liquefied petroleum gases must be

used on all threaded pipe connections. Check

with the local utility for location of manual

shutoff valve if required. (See figure 8 at

right.)

PAGE 7

FIGURE 8

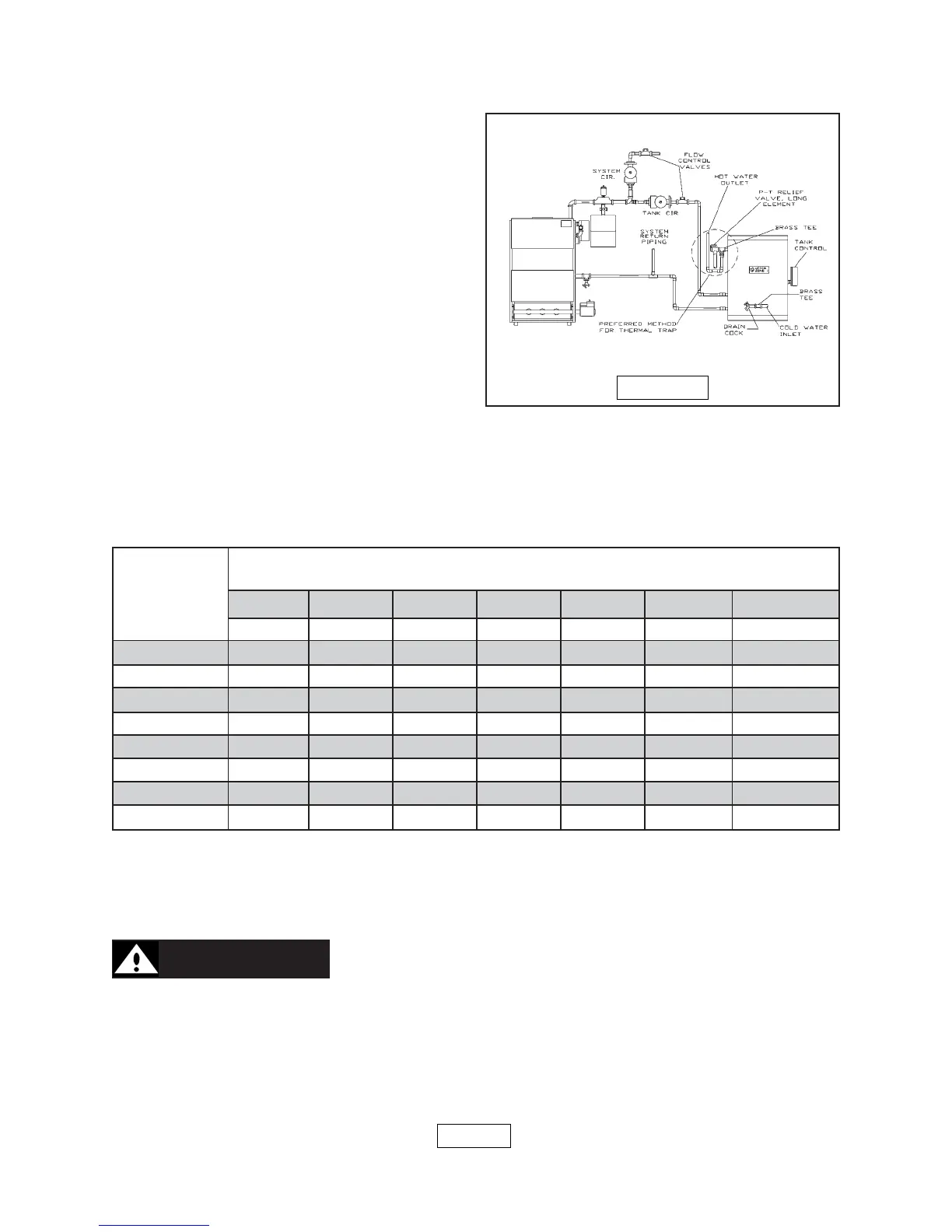

1. The gas line should be of adequate size to prevent undue pressure drop and never

smaller than the pipe size of the main gas control valve. See chart below.

Maximum Capacity of Pipe in Cubic Feet of Gas Per Hour (Cubic Meters per Hour)

(Gas pressure = 0.5 psig (3.45 kPa) or less pressure drop = .5 in.w/c(1.27 cm w/c))

Nominal

Length of Pipe

Iron Pipe

Size 10' 20' 30' 40' 60' 80' 100'

(3.05m) (6.10m) (9.14m) (12.19m) (18.29m) (24.38m) (30.48m)

1/2" 175 120 97 82 66 57 50

(1.27 cm) (4.96) (3.40) (2.75) (2.32) (1.87) (1.61) (1.42)

3/4" 360 250 200 170 138 118 103

(1.91 cm) (10.20) (7.08) (5.66) (4.81) (3.91) (3.34) (2.92)

1" 680 465 375 320 260 220 195

(2.54 cm) (19.26) (13.17) (10.62) (9.06) (7.36) (6.23) (5.52)

1.1/4" 1400 950 770 660 530 460 400

(3.18 cm) (39.65) (26.90) (21.81) (18.69) (15.01) (13.03) (11.33)

For additional information refer to Part 10, table 10-2 of the National Fuel Gas Code

Handbook, or in Canada, the CAN1-B149.1 and/or B149.2 Installation Codes for Gas-

Burning Equipment.

2. To check for leaks in gas piping, use a soap and water solution or other approved method.

WW

WW

W

ARNING:ARNING:

ARNING:ARNING:

ARNING: DO NOT USE AN OPEN FLAME.

3. The boiler and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of

1/2 psig (3.5 kPa).

4. The boiler must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

Loading...

Loading...