*****INTERNAL*****30 R_D proof- 26.10.2022 / 09:15:46- VaillantGroup\DOC-agt\Brand\VIH_QW_190_6\ENG\OI-II_GB_0020291525

60 Installation and maintenance instructions 0020291525_04

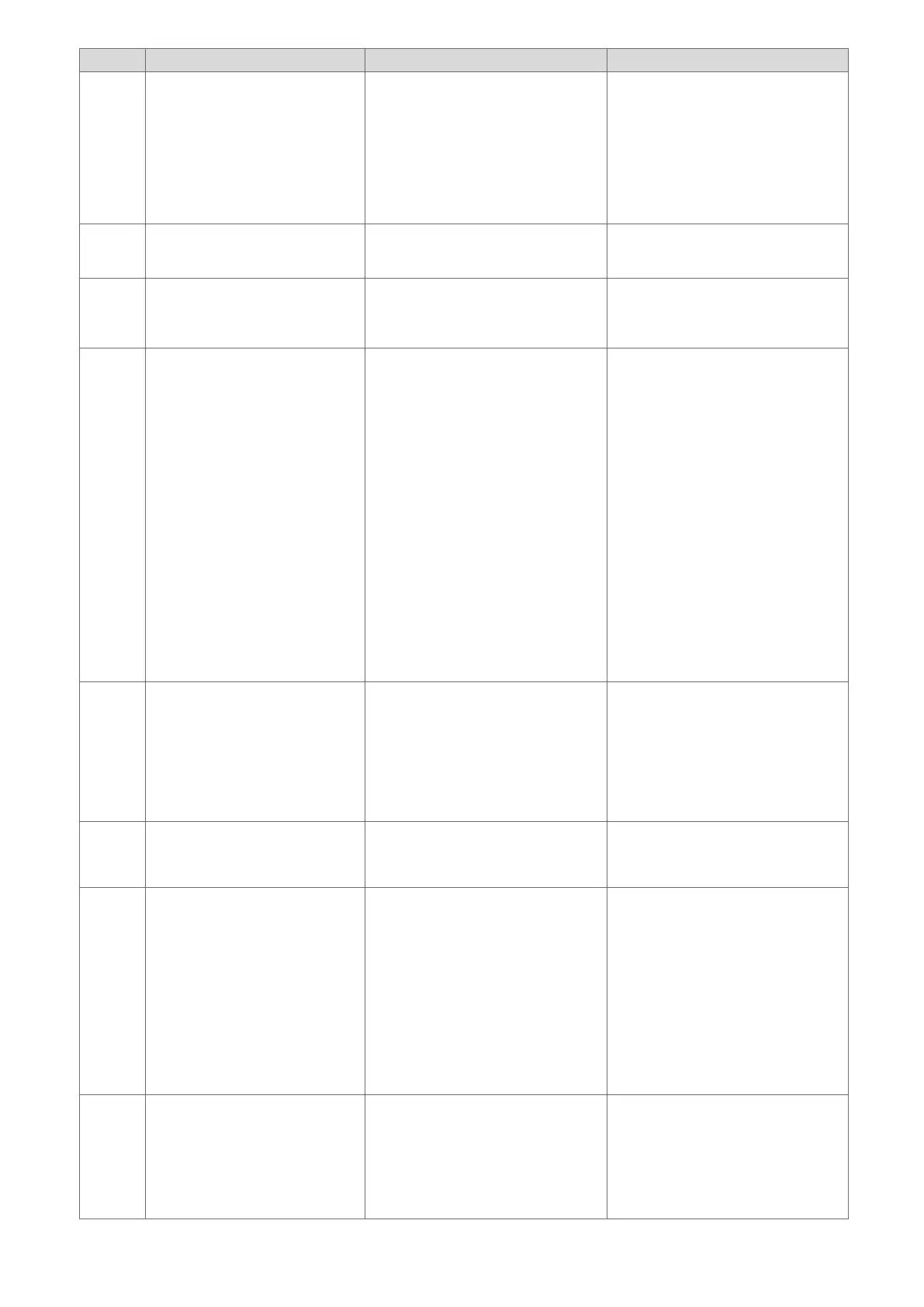

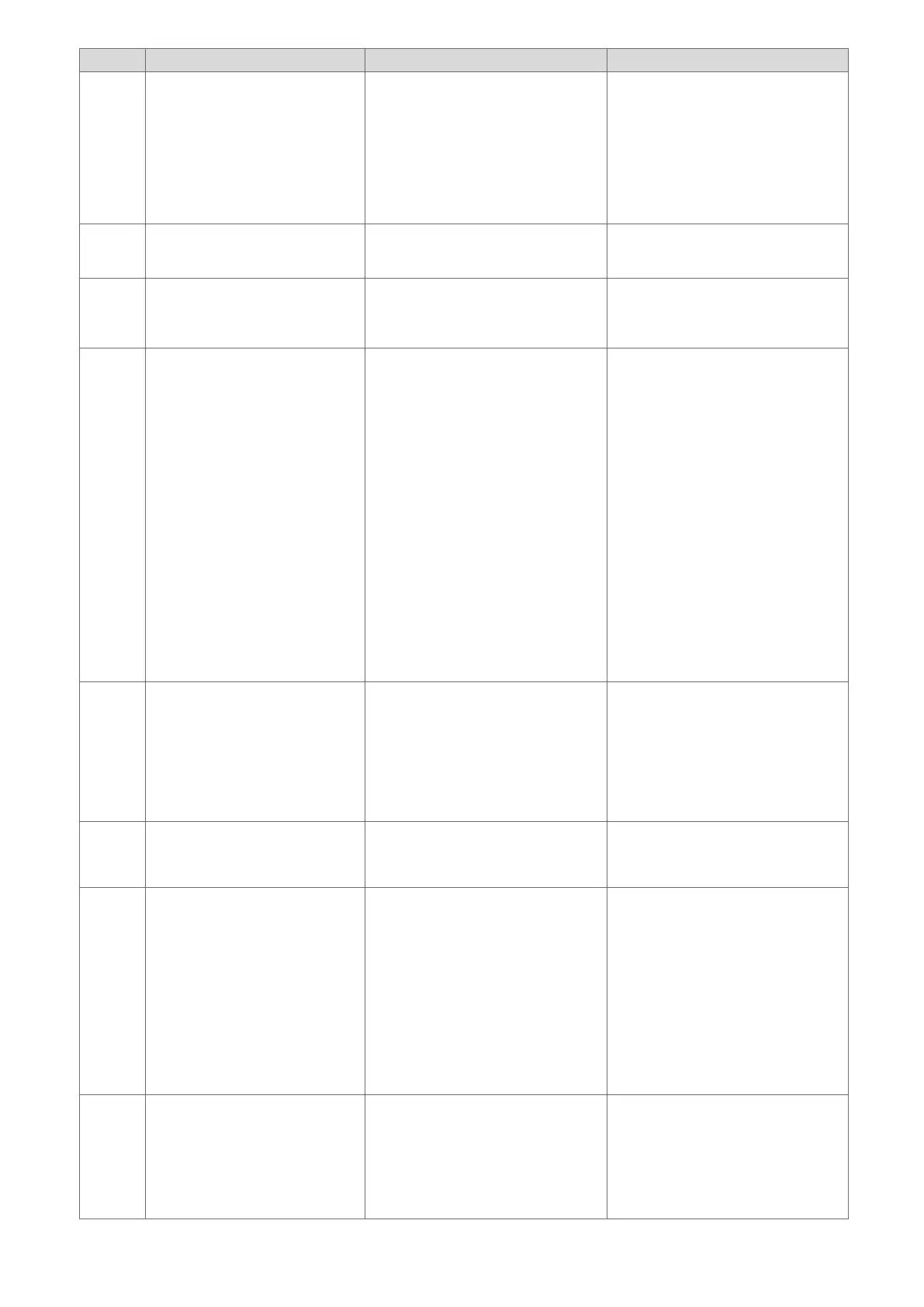

Code Meaning Cause

Remedy

F.819 Freq. converter fault: Overheating – Internal overheating of the frequency

converter

– Allow the frequency converter to cool

and restart the product

– Check the frequency converter's air

route

– Check that the fan is working cor-

rectly

– The maximum environmental tem-

perature of the outdoor unit (46 °C)

has been exceeded.

F.820 Connection fault: Building circuit

pump

– Pump does not report any signal

back to the heat pump

– Check the cable to the pump for

defects and, if required, replace it

– Replace the pump

F.821 Sensor fault: Immers. heater flow

temp.

– The sensor is not connected or the

sensor input has short-circuited

– Both of the flow temperature sensors

in the heat pump are defective

– Check and, if required, replace the

sensor

– Replace the wiring harness

F.823 Hot gas temperature switch open – The hot gas thermostat shuts down

the heat pump if the temperature

in the refrigerant circuit is too high.

Following a waiting period, the heat

pump attempts to start once more.

After three failed start attempts

in succession, a fault message is

displayed.

– Max. refrigerant circuit temperature:

110 °C

– Waiting period: 5 mins (after it first

occurs)

– Waiting period: 30 mins (after it

occurs a second time and any other

time after that)

– The fault counter is reset if both of

the following conditions are met:

– Heat requirement without switch-

ing off prematurely

– 60 mins uninterrupted operation

– Check the EEV

– Replace the dirt filter in the refrigera-

tion circuit, if required

F.824 Building circuit : Brinepressure

too low

Note

Can only occur in conjunction with

an installed and activated intermedi-

ate heat exchanger set.

Fault refers to the outdoor unit's

brine pressure sensor.

– Pressure loss in the building circuit

due to leakages or air pockets

– Building circuit pressure sensor

defective

– Check the building circuit for leaks

– Top up with water, purge

– Check the quality of the plug contact

on the PCB and on the wiring har-

ness

– Check that the pressure sensor is

working correctly

– Replace the pressure sensor

F.825 Sensor fault: Capac. inlet temp. – Refrigerant circuit temperature

sensor (vapour-forming) not con-

nected or the sensor input has short-

circuited

– Check and, if required, replace the

sensor and cable

F.1100 Immersion heater: Safety cut-out

open

The safety cut-out on the electric back-

up heater is open due to:

– Insufficient volume flow or air in the

building circuit

– The immersion heater is operated

when the building circuit is not filled

– Immersion heater operation at flow

temperatures above 89 °C trips the

safety fuse of the safety cut-out and

requires that the fuse be replaced

– Feed-in of external heat into the

building circuit

– Check the circulation in the building

circuit pump

–

If required, open the stopcocks

– Replace the safety cut-out

– Reduce or stop the external heat

that is entering

– Check that the dirt filter that is in

place is permeable

F.1117 Compressor: Phase failure – Defective fuse

– Incorrect electrical connections

– Mains voltage too low

– Compressor/low tariff power supply

not connected

– Energy supply company lockout for

over three hours

– Check the fuse

– Checking the electrical connections

– Check the voltage at the heat pump

electrical connection

– Set the max. duration of the ESCO

anti-cycling time to at least three or

more hours

Loading...

Loading...