*****INTERNAL*****30 R_D proof- 26.10.2022 / 09:15:46- VaillantGroup\DOC-agt\Brand\VIH_QW_190_6\ENG\OI-II_GB_0020291525

0020291525_04 Installation and maintenance instructions 61

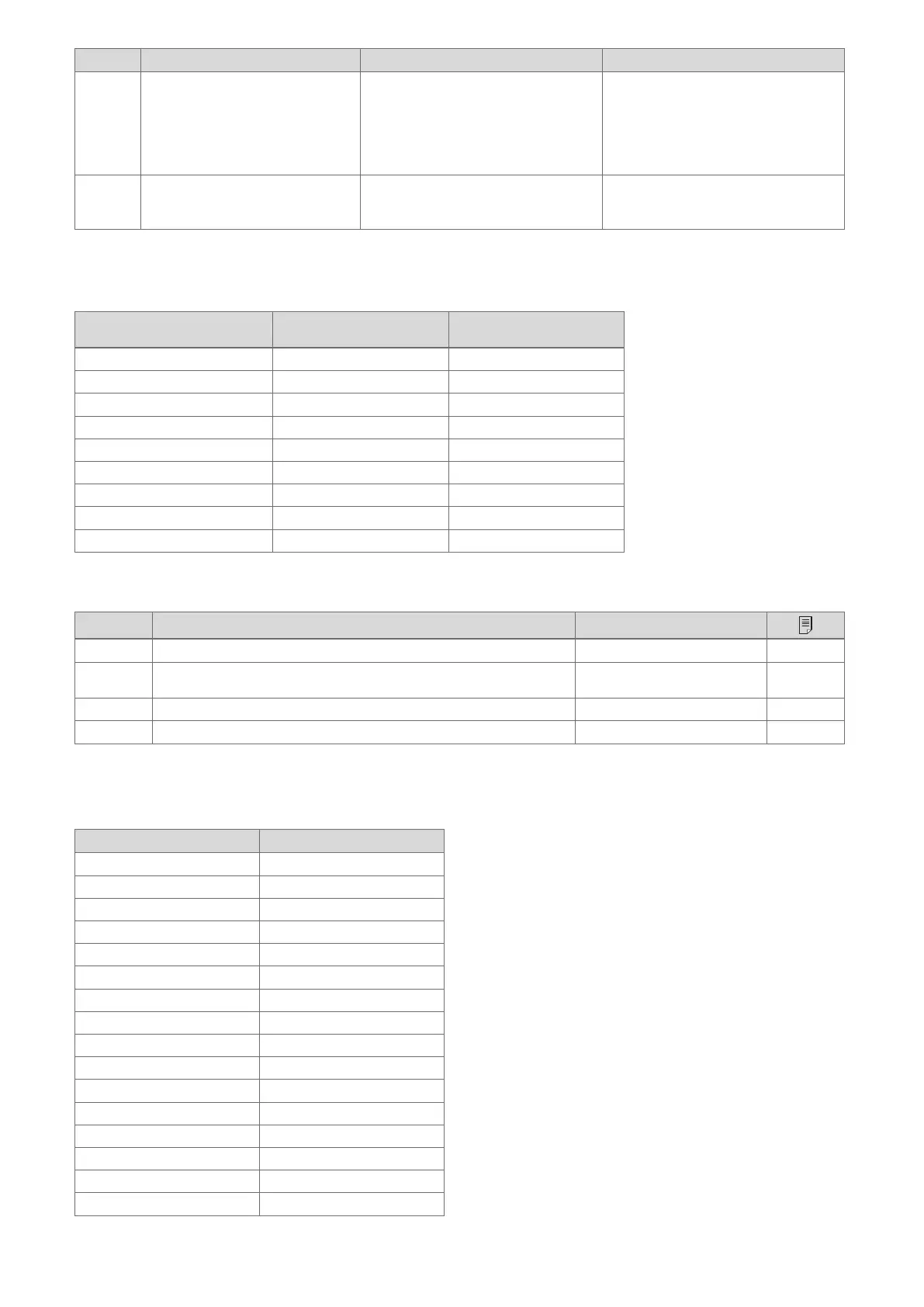

Code Meaning Cause

Remedy

F.1120 Immersion heater: Phase failure – Electric back-up heater defective

– Poorly tightened electrical connec-

tions

– Mains voltage too low

– Check the electric back-up heater

and its power supply

– Check the electrical connections

– Measure the voltage at the electrical

connection for the electric back-up

heater

F.9998 Connection fault: Heat pump –

eBUS cable not connected or con-

nected incorrectly

– Outdoor unit without supply voltage

–

Check the connection pipes between

the power supply PCB and control

PCB on the indoor and outdoor unit

K 5.4 kW back-up heater at 230 V and at 400 V

Internal control of the output

levels at 230 V and at 400 V

Power consumption Set value

0 0.0 kW

1 0.7 kW 1 kW

2 1.2 kW

3 1.8 kW 2 kW

4 2.2 kW 3 kW

5 3.2 kW

6 3.8 kW 4 kW

7 4.7 kW 5 kW

8 5.4 kW 6 kW

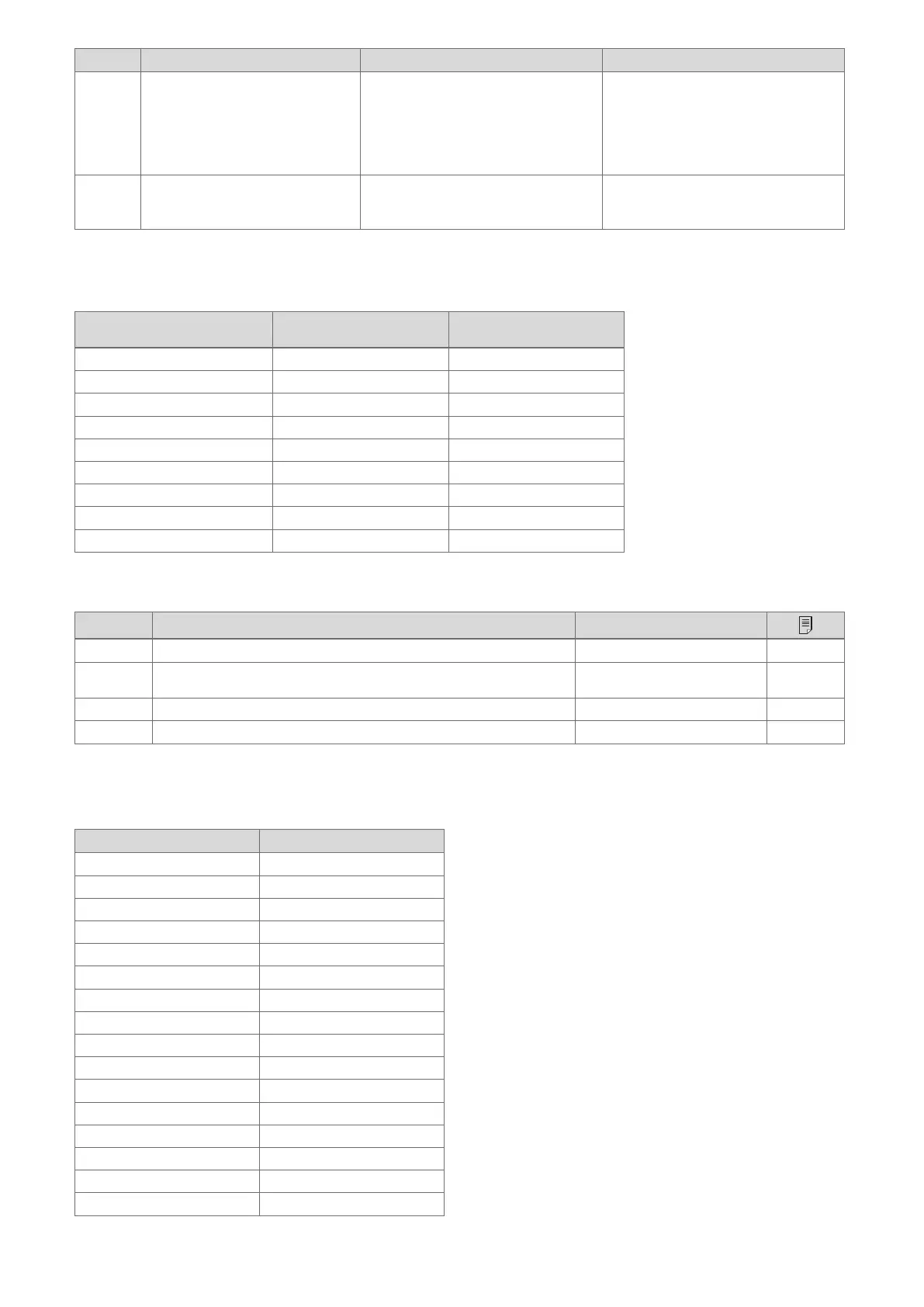

L Inspection and maintenance work

# Maintenance work Interval

1 Checking the pre-charge pressure of the expansion vessel Annually

43

2 Cleaning the domestic hot water cylinder If required, at least every

2 years

3 Check that the prioritising diverter valve can move easily (visually/audibly) Annually

4 Checking the electronics boxes, removing dust from the ventilation slits Annually

M Characteristic values for the internal temperature sensors, hydraulic circuit

Sensors: TT620 TT650

Temperature (°C) Resistance (ohms)

0 33400

5 25902

10 20247

15 15950

20 12657

25 10115

30 8138

35 6589

40 5367

45 4398

50 3624

55 3002

60 2500

65 2092

70 1759

75 1486

Loading...

Loading...