*****INTERNAL*****30 R_D proof- 26.10.2022 / 09:15:46- VaillantGroup\DOC-agt\Brand\VIH_QW_190_6\ENG\OI-II_GB_0020291525

0020291525_04 Installation and maintenance instructions 59

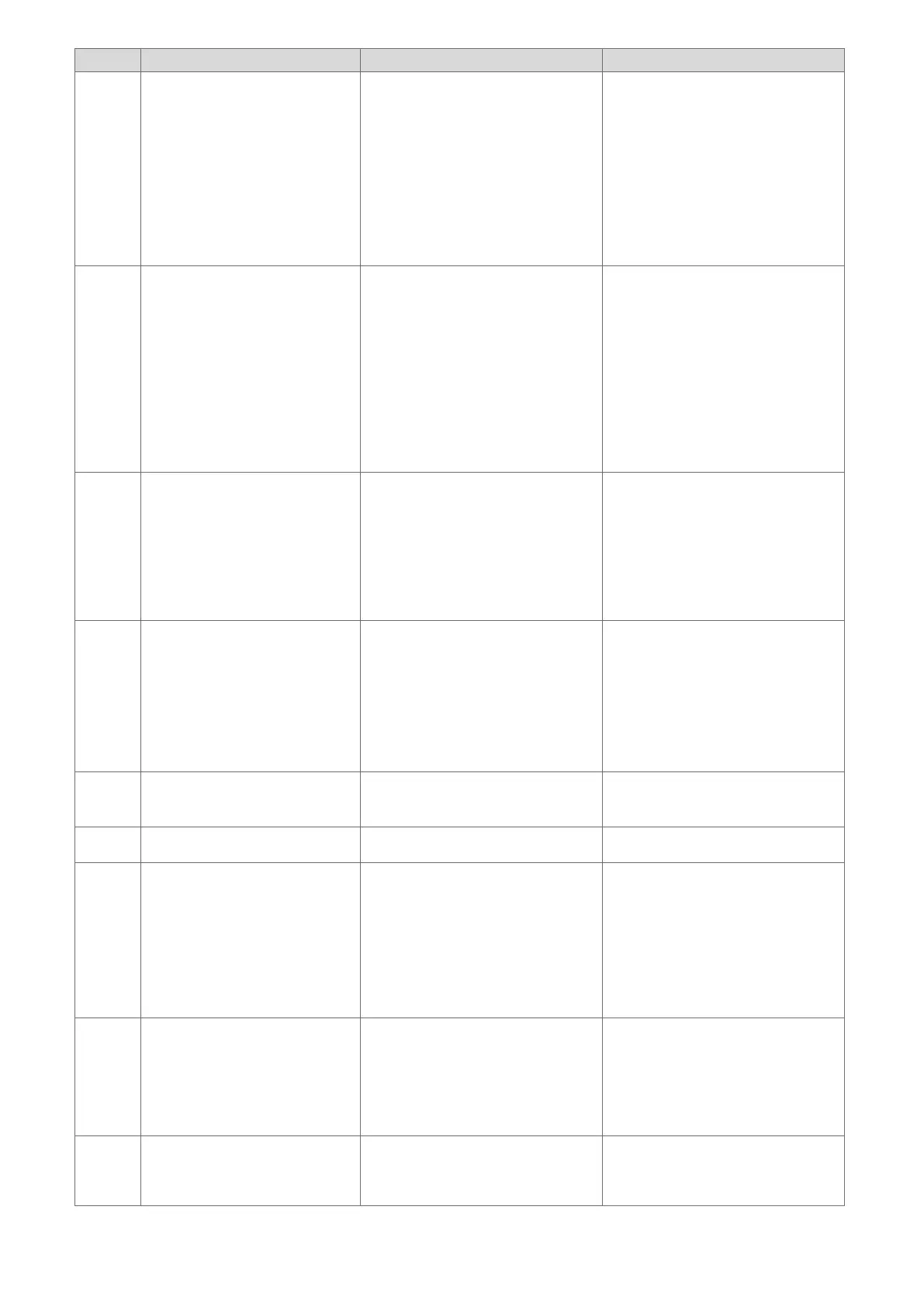

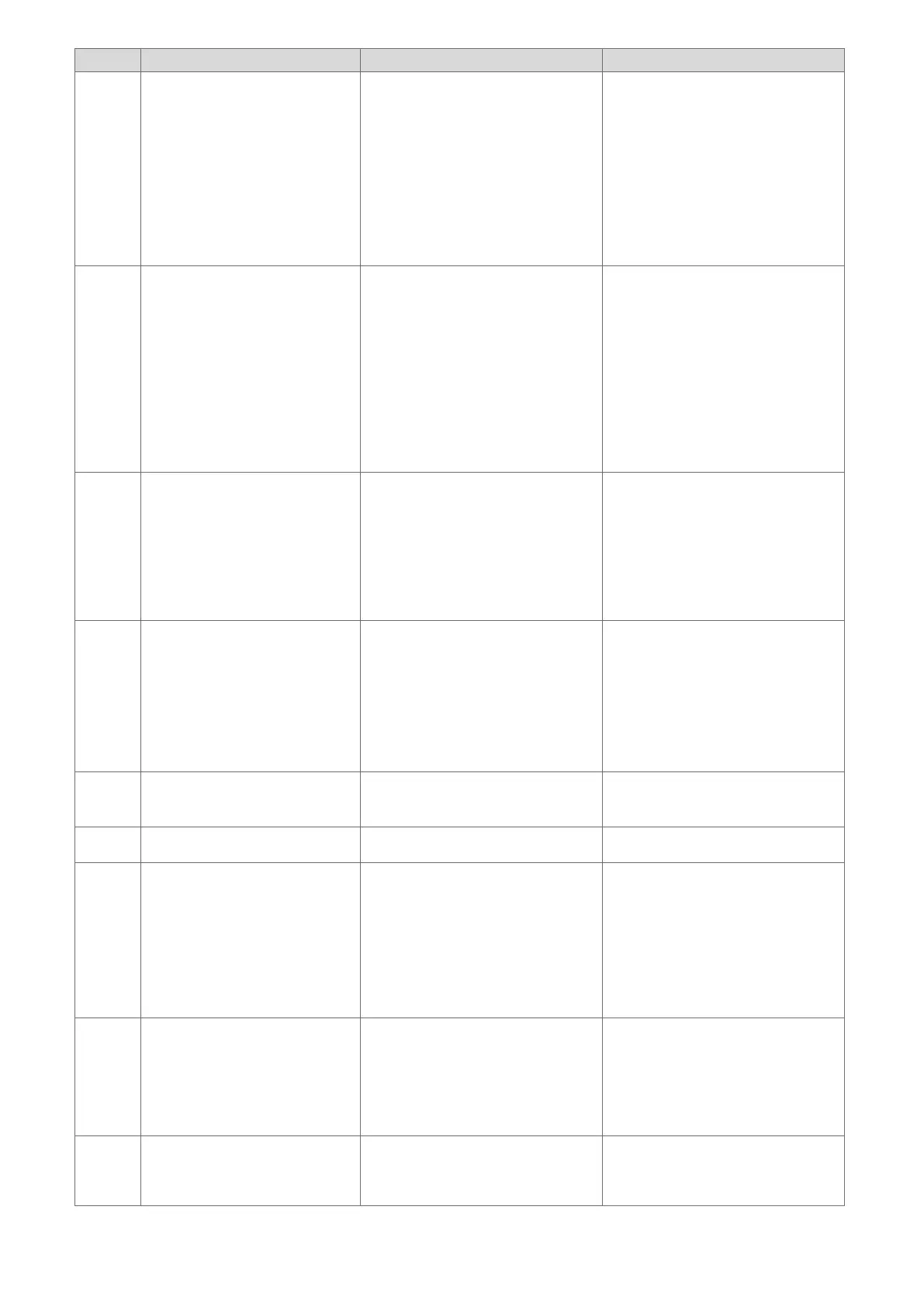

Code Meaning Cause

Remedy

F.741 Building circuit: Return temp. too

low

– During the de-icing, the return tem-

perature falls below 13 °C

– Ensure the minimum installation

volume is maintained; if required,

install a series return cylinder

– The fault message is displayed until

the return temperature increases to

above 20 °C.

– Activate the electric back-up heater

in the product's control panel and

in the system control in order to

increase the return temperature. The

compressor is blocked while the fault

message is present.

F.752 Fault: Frequency converter –

Internal electronics fault on the in-

verter PCB

– Mains voltage outside of 70 V–282 V

–

Check the integrity of the power sup-

ply cables and compressor connec-

tion cables

The plugs must audibly click into

place.

– Check the cable

– Check the mains voltage

The mains voltage must be between

195 V and 253 V.

– Check the phases

– Replace the frequency converter, if

required

F.753 Connection fault: Freq. conv.

n.recogn.

– Missing communication between the

frequency converter and the outdoor

unit's control PCB

– Check the integrity of the wiring

harness and plug connection and,

if required, replace them

– Check the frequency converter by

actuating the compressor safety

relay

– Read the assigned parameters for

the frequency converter and check

whether values are displayed

F.755 Fault: 4-port valve position not

correct

– Incorrect position of the 4-port di-

verter valve. If, in heating mode, the

flow temperature is lower than the

return temperature in the building cir-

cuit.

– The temperature sensor in the EEV

environment circuit displays an incor-

rect temperature.

– Check the 4-port diverter valve (is an

audible switching available? Use the

sensor/actuator test)

– Check that the coil is positioned

correctly on the 4-port valve

– Check the wiring harness and plug

connections

– Check the temperature sensor in the

EEV environment circuit

F.774 Sensor fault: Air inlet temp. – The sensor is not connected or the

sensor input has short-circuited

– Check and, if required, replace the

sensor

– Replace the wiring harness

F.785 Fan unit 2: Fan blocked – There is no confirmation signal stat-

ing that the fan is rotating

– Check the air route and, if required,

remove any blockages

F.788 Building circuit: Pump fault – The electronics system of the high-

efficiency pump has detected a

fault (e.g. dry running, blockage,

overvoltage, undervoltage) and has

switched off and locked the pump.

– Switch the heat pump off for at least

30 seconds (no current)

– Check the quality of the plug contact

on the PCB

– Check that the pump functions cor-

rectly

– Purging the building circuit

– Check that the dirt filter that is in

place is permeable

F.817 Freq. converter fault: Compressor – Defect in the compressor (e.g. short

circuit)

– Defect in the frequency converter

– Connection cable to the compressor

is defective or loose

– Measure the winding resistance in

the compressor

– Measure the frequency converter

output between the three phases, (it

must be > 1 kΩ)

– Check the wiring harness and plug

connections

F.818 Freq. converter fault: Mains

voltage

– Incorrect mains voltage for operating

the frequency converter

– Shutdown via the energy supply

company

– Measure and, if required, correct the

mains voltage

The mains voltage must be between

195 V and 253 V.

Loading...

Loading...