8. If fitting a new tap, remove the hexagonal nut at the mounting bracket end of the

old tap and fit to the replacement tap. Refit in the reverse order. When refitting, make

sure that the tap spindle is in the correct relationship relative to the control pivot

bracket. Rotate the pivot bracket fully clockwise. The tap spindle should “bottom out”

(i.e. the tap should be fully open) after the pivot bracket has actuated the ignition

microswitch but before it has pushed the microswitch leaf against the microswitch

body.

When refitting the thermocouple and interrupter block, make sure that the microswitch

wires are properly secured to give a good electrical contact.

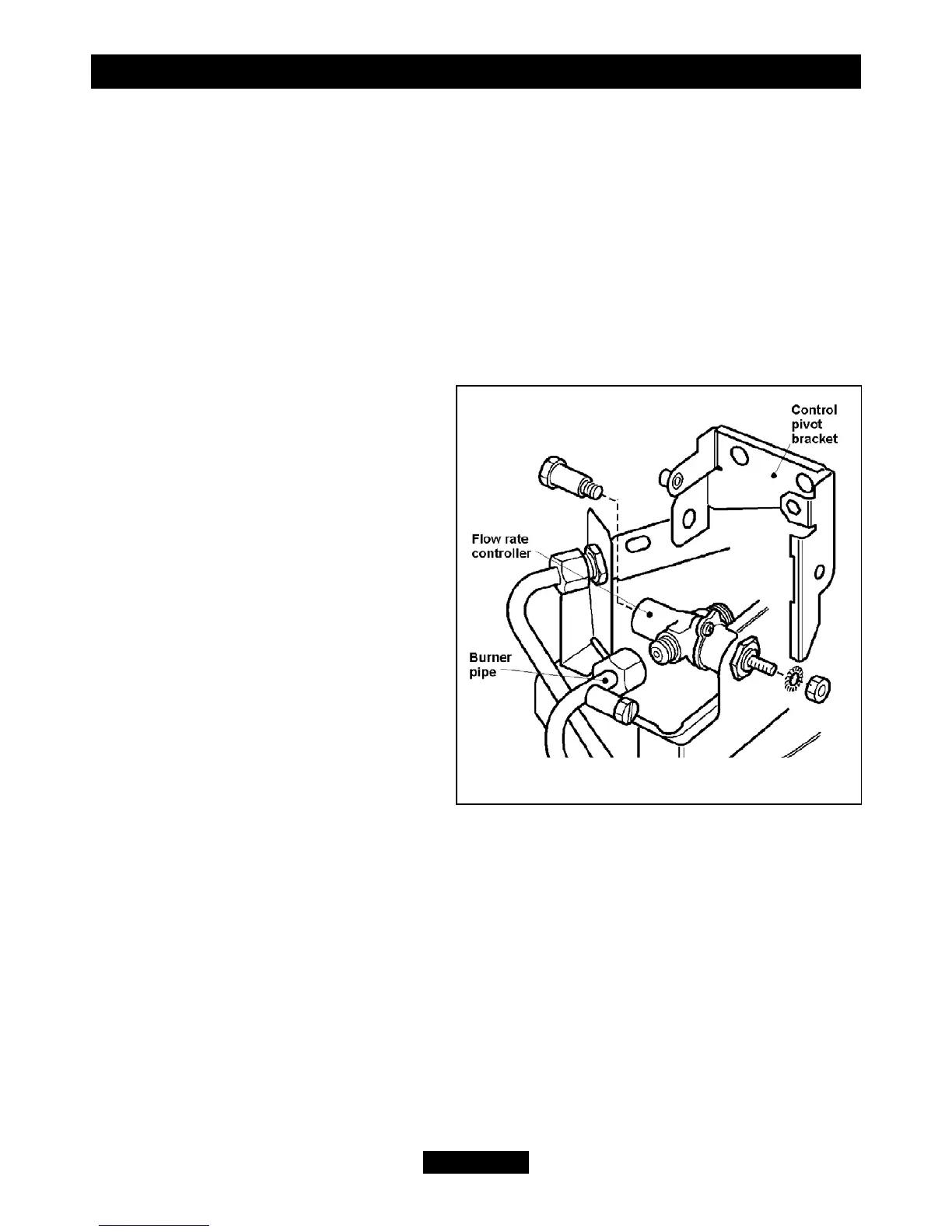

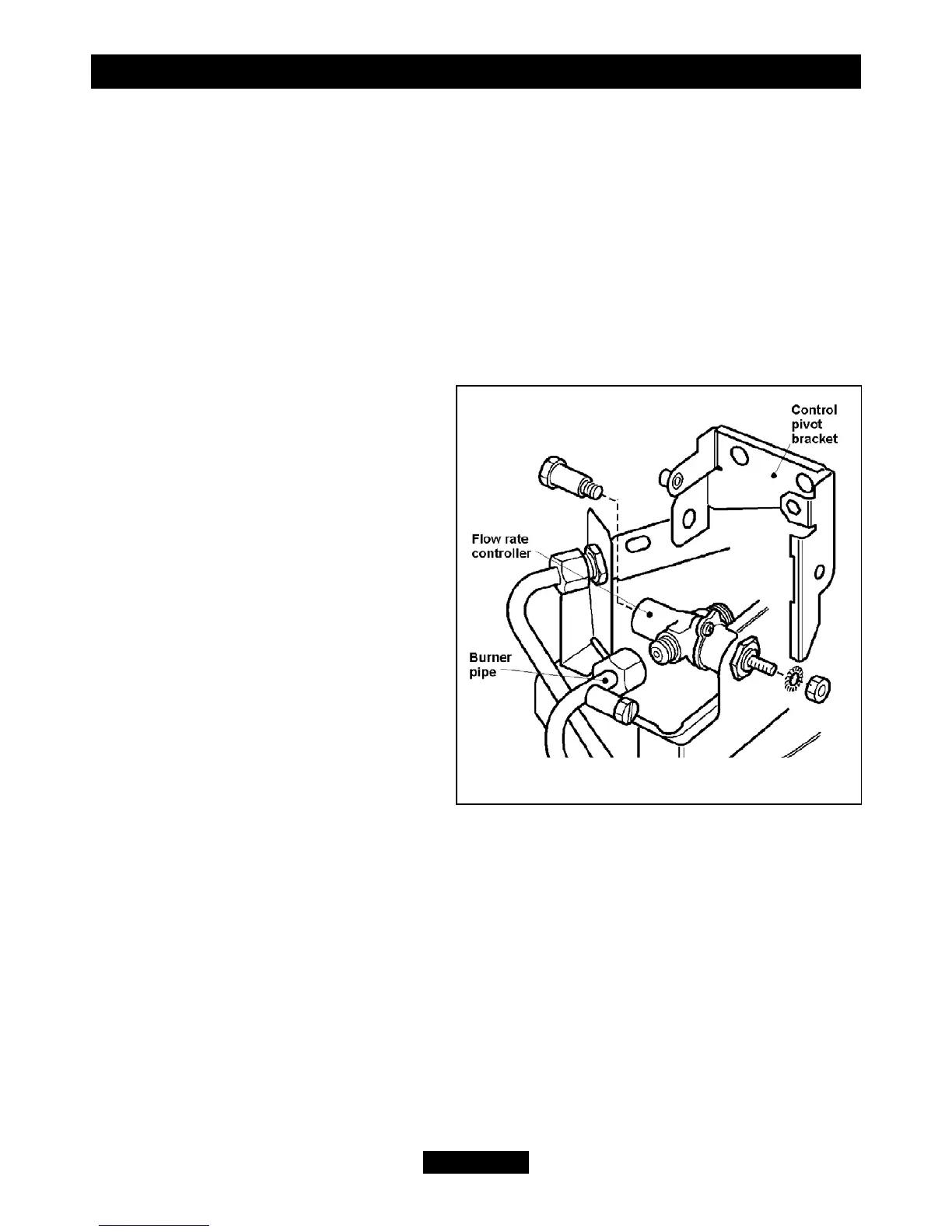

17.12 To remove the gas flow rate controller.

(See figure 58).

1. Remove the burner unit (See section

17.7).

2. If lying the burner on its back, ensure

that the work surface is suitably

protected. This will avoid damage to the

work surface.

3. Detach the microswitch cover (See

section 17.2 paragraph 2).

4. Detach the shut-off tap as detailed in

section 17.11 paragraphs 2-6.

5. Detach the burner pipe from the

controller. Support the controller while

detaching to prevent excessive strain.

6. Remove the nut and washer securing

the control pivot bracket to the controller

at the front. Support the pivot bracket

while removing the nut to prevent

possible damage to the microswitch.

7. Remove the hexagonal bolt securing the control pivot bracket to the controller at

the rear.

8. Detach the control pivot bracket.

9. Remove the hexagonal nut securing the controller to the front mounting bracket

and remove the flow rate controller.

10. Refit in the reverse order.

© GDC Group Ltd. 2011

Page 46

INSTALLER GUIDE

Figure 58. Flow rate controller

Loading...

Loading...