BDR-720D Adela PRO

2.5.3 MACHINE LUBRICATION

When working with lubricants, observe the basic hygiene regulations and observe the environmental protection

regulations and laws.

For trouble-free and easy movement of all mechanical parts, pay sufficient attention to lubrication.

2.5.3.1 ENGINE OIL CHANGE

If you are not manually skilled enough, entrust this work to a specialist workshop.

• Follow the engine operating instructions for the type, quantity, and method of engine oil changing.

• Standard interval of oil change, specified by the engine manufacturer, reduce it by half. When mowing grasslands, a large amount

of dust and pollen particles is always produced.

2.5.3.2 TRANSMISSION OIL LEVEL CHECK

• The oil filling – see

Table

17

on page

26

- does not need to be changed throughout the service life of the transmission.

For any potential replenishment or change

53

f the oil filling only use the specified specification, using oil of another specification

reduces the service life of the transmission and exposes you to potential issues with its functionality.

• To measure the level, use the engine oil dipstick - 19 on

Fig.

1

. The machine must stand on a horizontal surface - garage or

workshop is ideal.

1) Wipe the dipstick thoroughly from the engine oil.

2)

Fig. 17

A Pull out the rubber plug of the inspection and filling hole - left of the shift lever foot.

3)

Fig. 17

B Insert the dipstick into the hole at the angle of about 30° to the chassis wall and parallel to the longitudinal axis of

the machine. Slide it all the way in, do not press hard on the dipstick. When measuring the oil level, the dipstick must rest on the

front and rear edges of the hole.

4)

Fig. 17

C The correct oil level is reached, when the oil mark on the dipstick is visible just at the collar, the distance is about 20

mm from the end of the dipstick.

5) Before returning the dipstick to the engine, wipe it thoroughly of any residual transmission oil and dirt.

2.5.3.3 LUBRICATION POINTS

A spray oil that repels water and dust particles or a liquid "white" vaseline spray is suitable for lubrication. Of the solid

lubricating greases, any lubricant intended for lubrication of water pumps is fully sufficient. However, its application usually

requires the dismantling of the corresponding slide assembly.

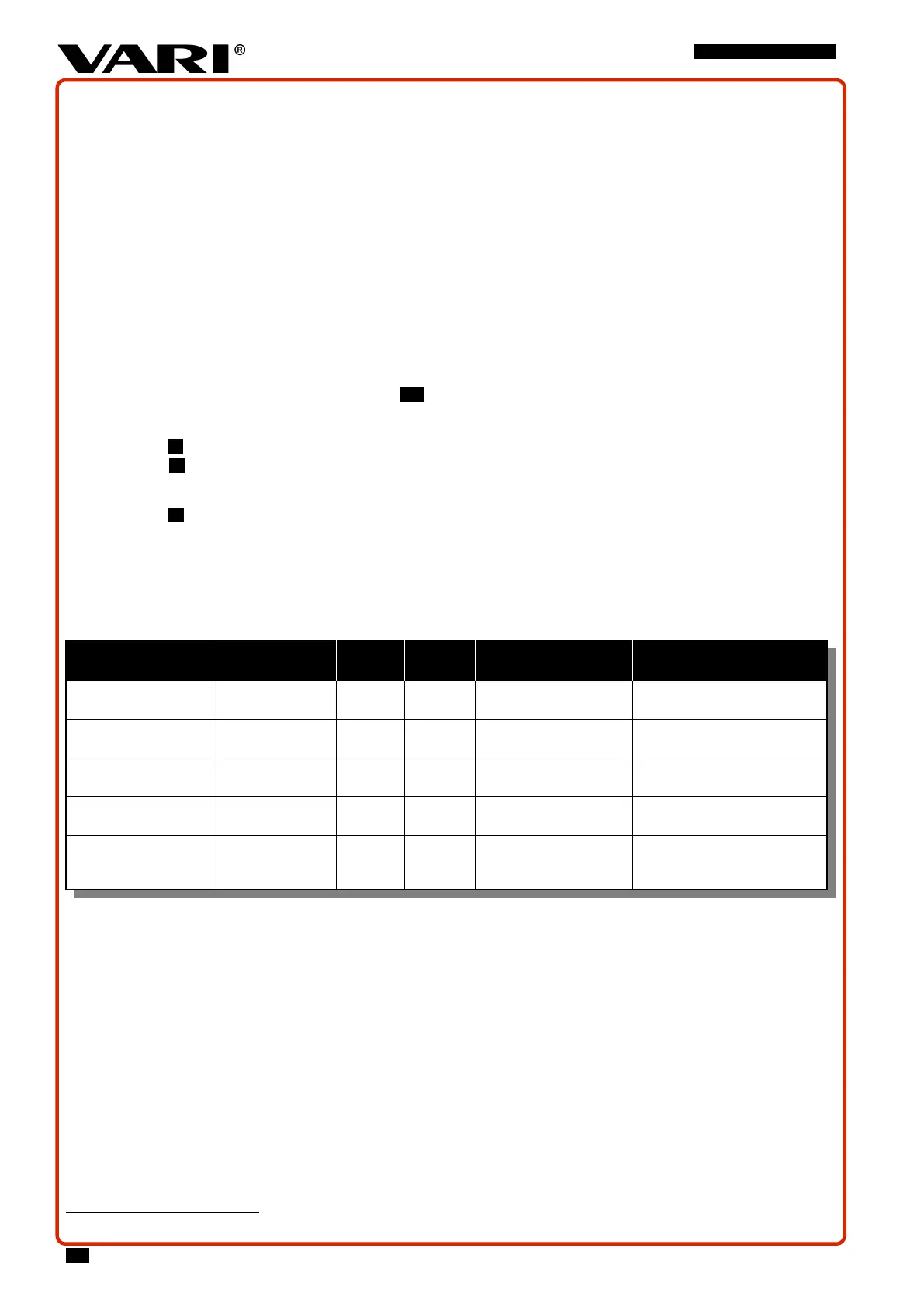

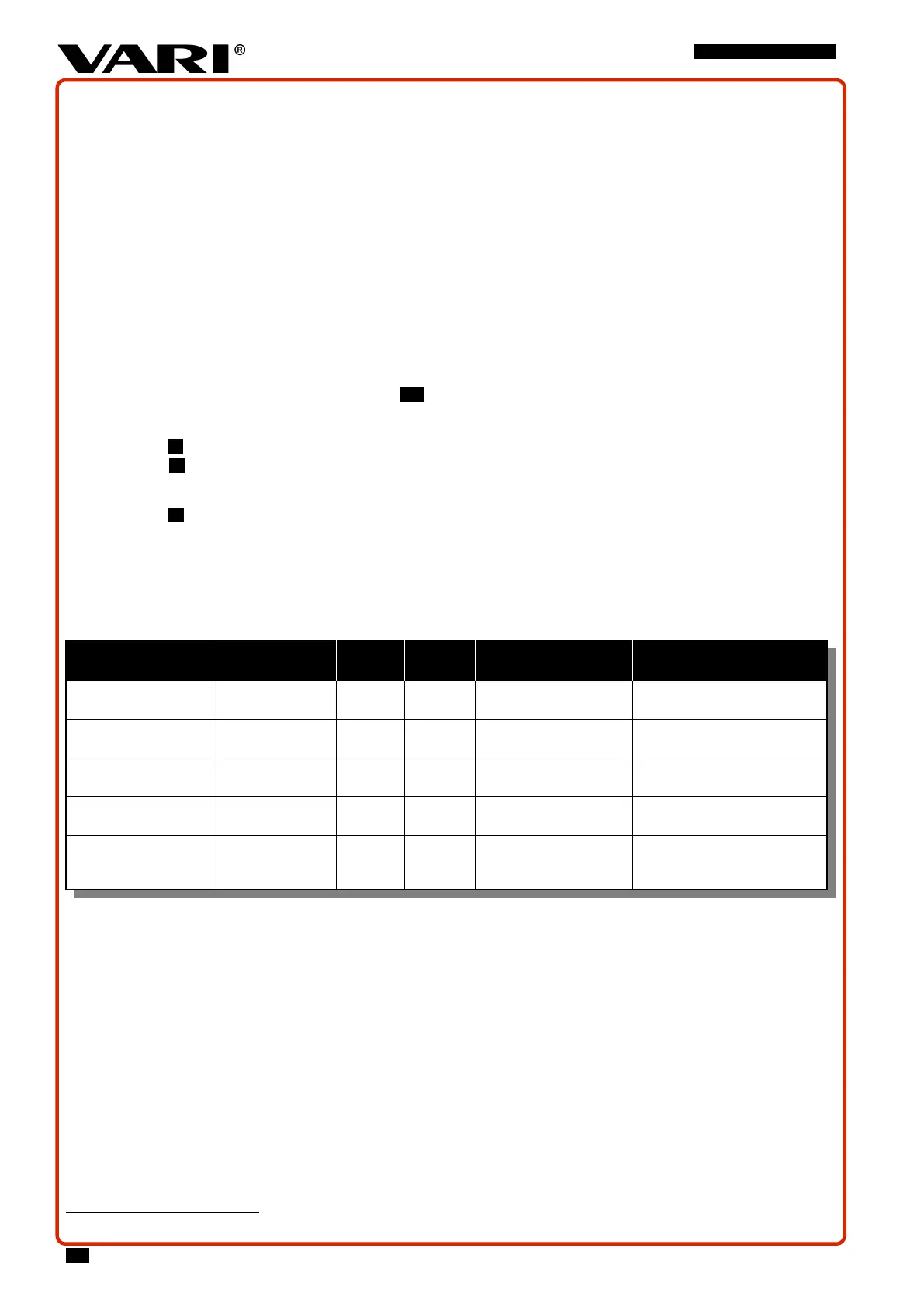

Lubrication point -

description

Interval within

season

After

season

Lubricant Figure Note

Bowden cables / levers at least 2x yes Oil

Fig. 13, Fig. 20, Fig. 21

Cable entry into the bowden

cable / pins

Cutting disc drive pulley

housing

every 10 hours yes Oil/grease

Fig. 14

Pulley pin - the cutting disc cover

must be removed

Travel clutch pulley - yes Oil/grease

Fig. 15

Pulley pin - shift lever and

handlebars must be removed.

Brake key - yes Oil

Fig. 14

Spanner pin - the cutting disc

cover must be removed

Bowden cable divider - yes Vaseline

Fig. 16

Bowden cable slider - it is

necessary to click the lid of the

switchboard.

Table 23: Lubrication intervals

2.5.3.4 TYRES

• Check the tyre pressure before working with the machine.

• If there is a permanent tyre pressure leakage, make sure that there is no defect on the tyre tube – repair it if necessary.

If you are not sufficiently manually skilled, have the operations done by an authorized service centre.

• Keep the same pressure in the left and right wheels – the machine better holds a straight track.

Do not exceed the maximum tyre pressure – there is a risk of the tyre explosion!

MAXimum tyre pressure: 20 PSI (138 kPa or 1.38 bar or 1.36 atm or 0.14 MPa)

Operating

54

tyre pressure: 18 PSI (124 kPa or 1.24 bar or 1.22 atm or 0.12 MPa)

• Before the machine is put away for a longer time, refill the pressure to MAX.

Whenreplacing a wheel or tyre due to tread wear or an irreparable defect, always replace the wheels or tyres on both sides

of the machine. The different diameter of the new and worn wheel will cause the machine to turn spontaneously and the

vegetation will not be cut evenly.

53

When changing the transmission oil, the transmission must be removed from the machine. Always entrust this activity to an authorised service centre.

54

If the tyre pressure is lower than indicated, the tyre structure will be damaged, and its service life will be significantly reduced.

32

Loading...

Loading...