29

30

2.1 Brief introduction

ARC 200G / ARC 200K welding machines adopts the latest pulse width modulation (PWM)

technology and insulated gate bipolar transistor (IGBT) power module, which can change work

frequency to medium frequency so as to replace the traditional hulking work frequency

transformer with the cabinet medium frequency transformer. Thus its characterized with

portable, small size, light weight, low consumption and etc.

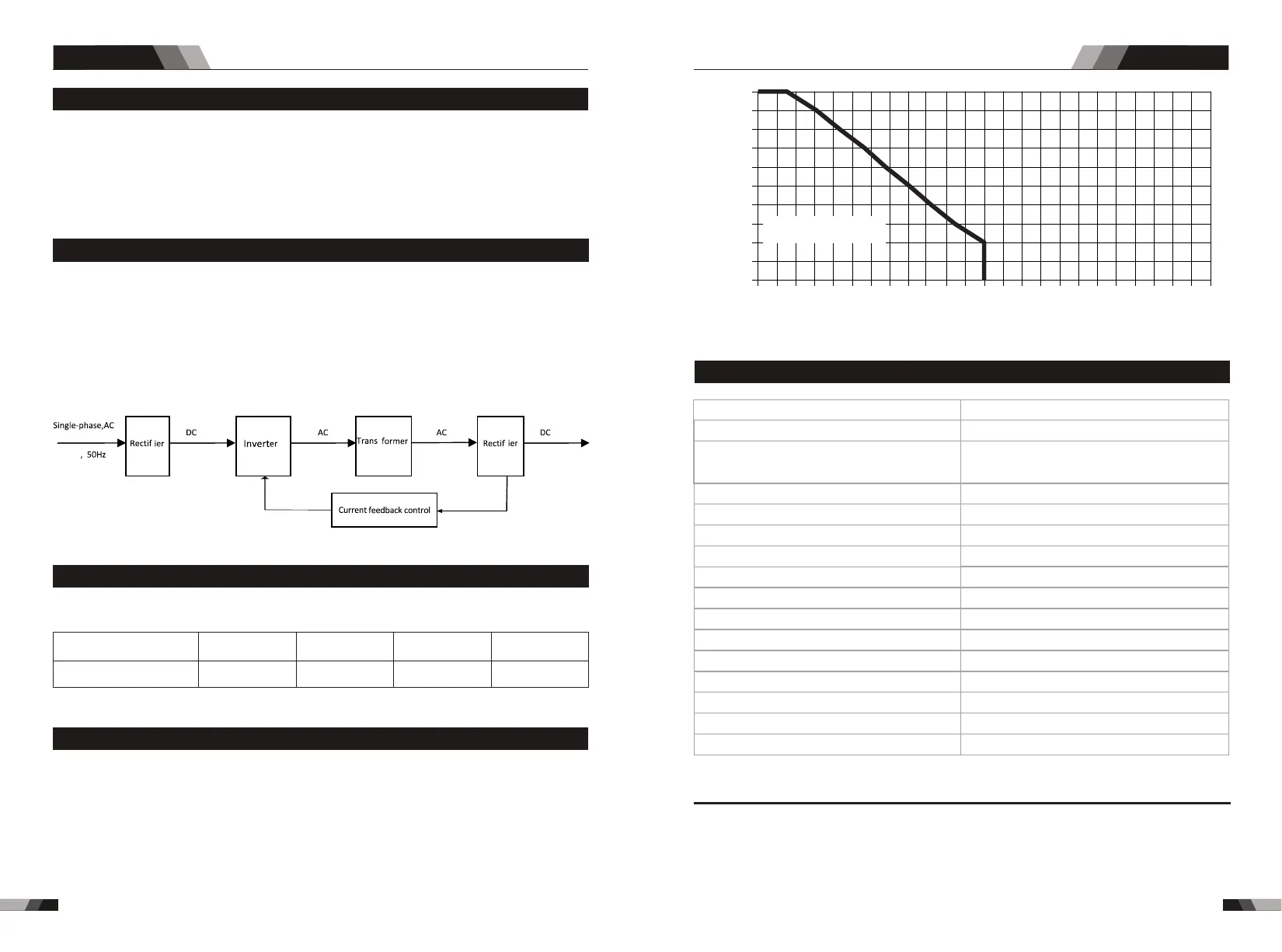

2.2 Working principle

230V

The working principle of ARC 200G / ARC 200K welding machines is shown as the

following figure. Single-phase 230V work frequency AC is rectified into DC(about 312 V),

then is converted to medium frequency AC (about 20-40KHz) by inverter device (IGBT

module), after reducing voltage by medium transformer (the main transformer) and rectifying

by medium frequency rectifier (fast recovery diodes),then is outputted DC .The circuit adopts

current feedback control technology to insure current output stably. Meanwhile, the welding

current parameter can be adjusted continuously and steplessly to meet the requirements of

welding craft.

Specification

Welding current

2. 3 Welding electrodes specifications

Adjust knobs of welding current , make welding current is adequate to welding electrode

according with as following:

φ2.5

φ3. 2

φ4. 0 φ5. 0

70-100A

110-140A 170-230A 230-280A

2.5 Specifications

Nominal Supply Voltage

Nominal Supply Frequency

Welding Current Range

Single Phase Generator Requirement

Welding Output, 40ºC, 10 min.

Open circuit voltage

Protection Class

Maximum Input Current

Effective Input Current

Due to variations that can occur in manufactured products, claimed performance, voltages,

ratings, all capacities, measurements, dimensions and weights quoted are approximate

only. Achievable capacities and ratings in use and operation will depend upon correct

installation, use, applications, maintenance and service.

10 - 200A

16A

35.8A

14.4KVA

200A @ 20%, 28V 89A @ 100%,23.6V

IP23

Description

Weight

Power Source Dimensions

Cooling

Welder Type

European Standards

Number of Phases

Fan Cooled

Inverter Power Source

EN 60974-1 / IEC 60974-1

1

230V +/- 15%

50/60Hz

62V DC

NOTE

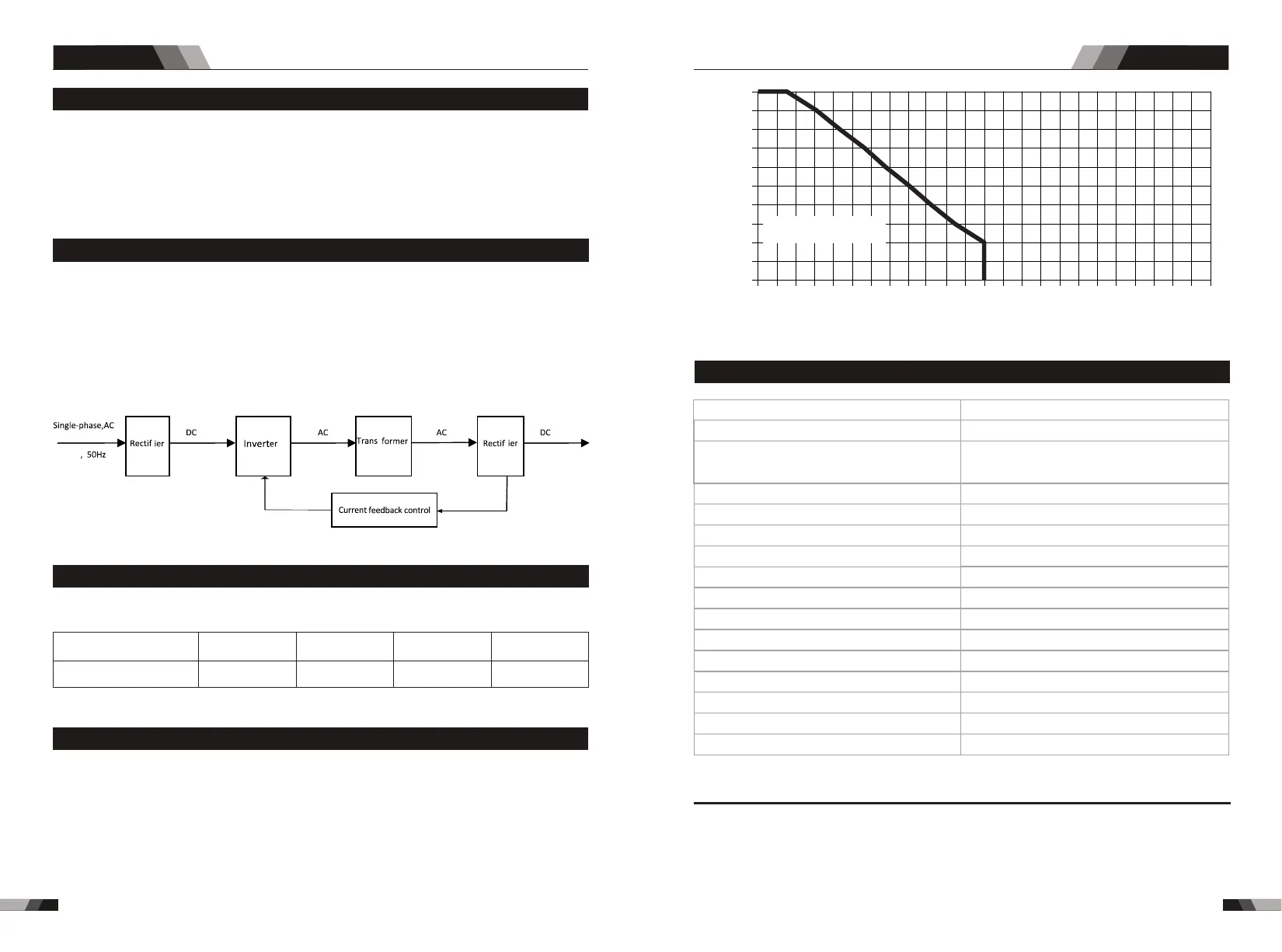

2.4Duty cycle

The rated duty cycle of a Welding Power Source is a statement of the time it may be

insulation of the component parts. To explain the 10 minute duty cycle period the following

example is used. Suppose a Welding Power Source is designed to operate at a 20% duty

cycle, 200 amperes at 28 volts. This means that it has been designed and built to provide

the rated amperage (200A) for 4 minutes, i.e. arc welding time, out of every 10 minute

the Welding Power Source must idle and be allowed to cool.

operated at its rated welding current output without exceeding the temperature limits of the

period (20% of 10 minutes is 4 minutes). During the other 6 minutes of the 10 minute period

SummarySummary

ARC SERIES EQUIPMENTARC SERIES EQUIPMENT

Duty Cycle(PERCENTAGE)

Welding Current(AMPS)

10 0 12 0 14 0 16 0 1 8 0 20 0 22 0

0

10

20

30

40

50

60

70

80

90

10 0

24 0 26 0 28 0 3 0 0 3 2 00

Sicherer Arbeitsvorgang

(STICK)

ARC 200G / ARC 200K

2.4kg & 2.5kg

H225mmxB97mmxT170mm

H235mmxB110mmxT175mm

Loading...

Loading...