Ventis™ MX4 Product Manual

© 2014 Industrial Scientific Corporation

24

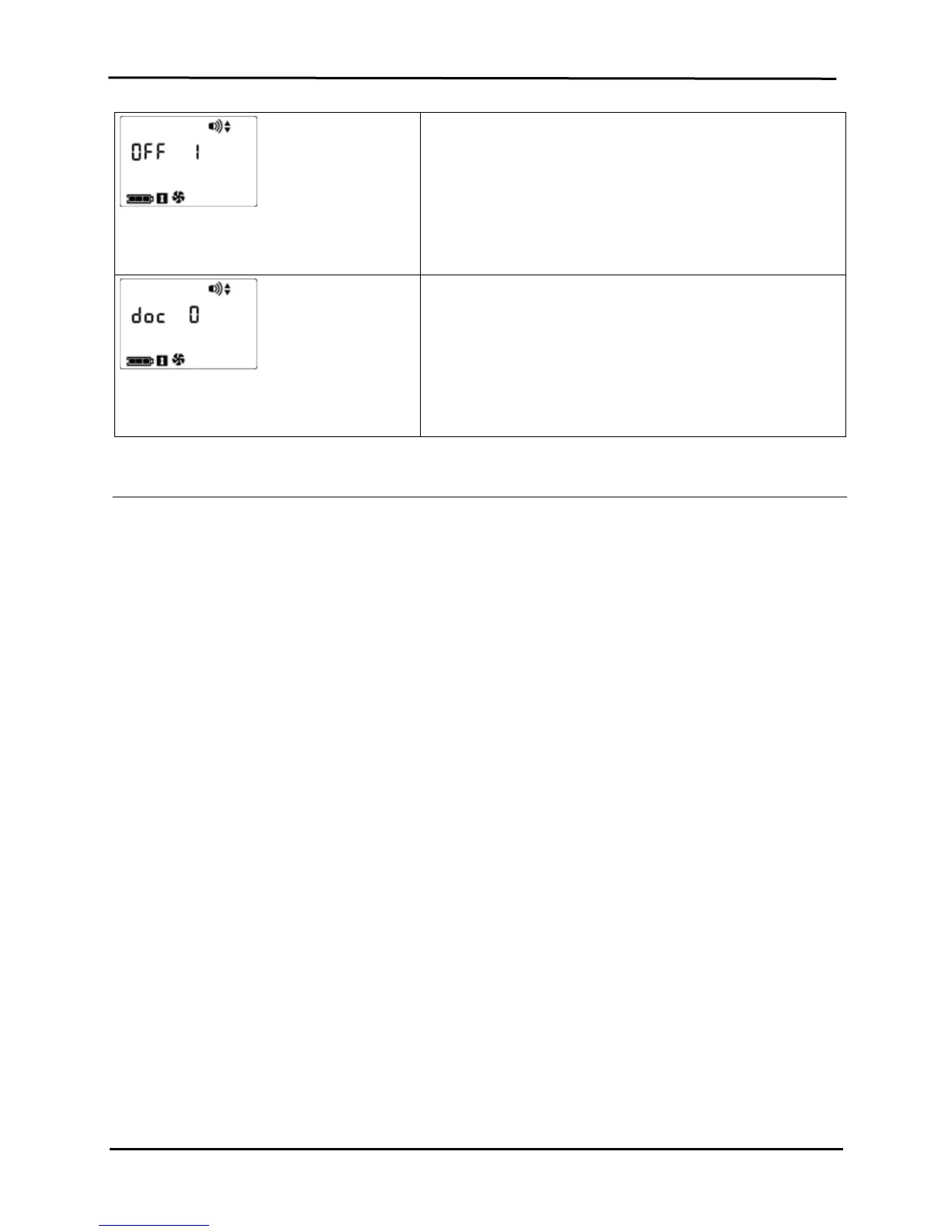

Shutdown In Alarm Screen

Options

0 = Disallows shutdown

1 = Allows shutdown

Disallow or allow operator-activated shutdown when the unit is in

alarm.

Press ENTER to edit the value, if needed.

Press ON/OFF/MODE to set the value and advance to the next

configuration mode screen.

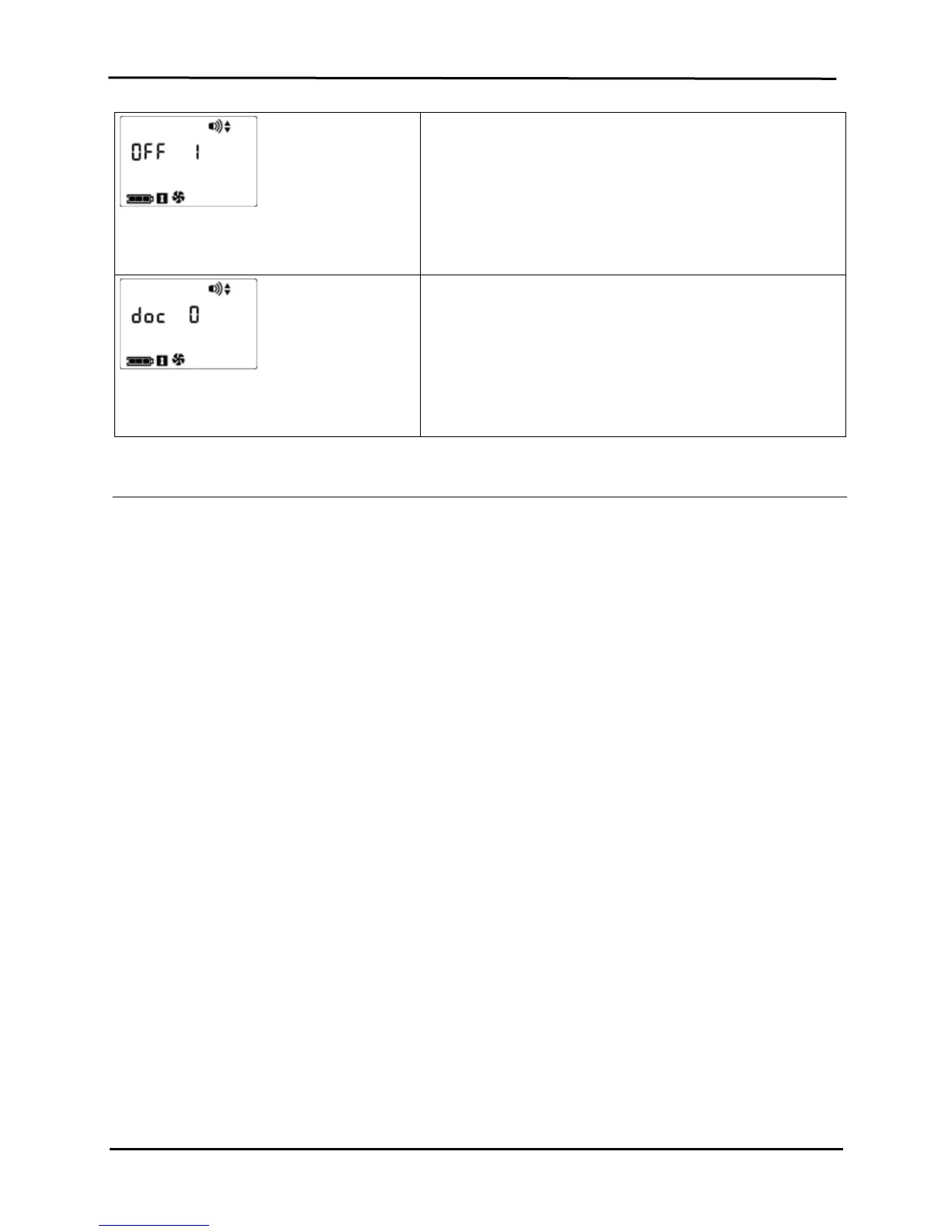

Alarm on Dock Screen

Options

0 = Disable/off

1 = Enable/on

Disable or enable alarm indicators when the unit is docked.

Press ENTER to edit the value, if needed.

Press ON/OFF/MODE to set the value and advance to the next

configuration mode screen.

►Monitor Use and Service

Proper monitor use and service includes everything from bump testing and calibration to keeping the monitor clean,

proper air sampling, and the replacement of parts and components. Beginning with calibration and bump testing, the

following sections provide information and instruction on all use and service tasks.

ZERO, CALIBRATION, AND BUMP TESTING

Gas detection instruments are potentially life-saving devices. When completed regularly, the procedures defined

below help to maintain proper instrument functionality and enhance operator safety.

Procedures

Configuration. The configuration process allows qualified personnel to review and adjust a unit's settings.

Bump Test (or "functional test"). Bump testing checks for sensor and alarm functionality. The installed sensors are

briefly exposed to expected concentrations of calibration gases that are greater than the sensors’ low alarm set

points. When one or more sensors “pass” the test, they are “functional” and the unit will alarm. Each sensor’s “pass”

or “fail” result is indicated on the unit’s display.

Note: a bump test does not measure for sensor accuracy (see “Calibration”).

Zero. Zeroing sets each installed sensor to recognize the ambient air as clean air. If the ambient air is not truly clean

air, any gasses that are present and relevant to the installed sensor types will be measured and displayed as zero.

Readings will be inaccurate until the unit is correctly zeroed in truly fresh air or with a zero air cylinder.

Calibration. All sensors gradually degrade over time. This diminishes a sensor's ability to measure gas

concentrations accurately; however, regular calibrations adjust the instrument to compensate for this decline in

sensitivity. During calibration, the installed sensors are exposed to expected concentrations of calibration gases and,

when needed, the instrument will self-adjust to ensure the accurate measurement and display of gas concentration

values.

Note: when a sensor has degraded beyond an acceptable level, no further adjustment is possible and the sensor will no longer pass

calibration.

Peak Readings. The instrument stores the highest detected gas readings, the "peak readings" or "peaks". Bump

testing and calibration will often register new peak readings. Therefore, the clearing of the peak readings should

follow each calibration. The instrument operator may also wish to clear the peak readings after a bump test, before a

change in location, or after an alarm is addressed and cleared.

Loading...

Loading...