Operation - 33

GENERAL OPERATION

Daily Inspection

WARNING

Always engage the parking brake, shut o the pow-

er unit engine, remove the ignition key, and ensure

that all moving parts have come to a complete stop

before inspecting the components, or attempting

any repair or adjustment.

1. Park the machine on a level surface, with the en-

gine shut o and all uids cold.

2. Perform a visual inspection of the power unit.

Look for loose or missing hardware, damaged

components, or signs of wear.

3. Inspect the ROPS structure and seat belt for dam-

age or signs of wear.

4. Inspect the battery, the electrical connections, and

the lights.

5. Ensure the parking brake is set to the proper ten-

sion. Adjust the tension as required.

6. Inspect the hydraulic hoses and the hydraulic t-

tings to ensure tight, leak free connections.

7. Inspect the fuel lines to ensure tight, leak free

connections.

8. Inspect the belts for damage or excessive wear.

Refer to the Belt Inspection section of this manual.

9. Inspect the power unit’s engine oil level, the

hydraulic oil level, the coolant level, and the fuel

level. Add uid or service as required.

ATTENTION

If the power unit is equipped with a cab and heater

kit and the outside air temperature is 4° C (40° F)

or above, the radiator bae must be removed and

replaced with the radiator screen.

10. Ensure the radiator screen, the air cleaner, and

the engine compartment are clean.

11. Check the tires for proper ination.

12. Test the operator safety interlock system.

Starting the Engine

CAUTION

Use of ether or starting uids may cause engine

damage and/or personal injury. Do not use ether or

starting uids to aid in starting the engine.

The 4520 is equipped with an interlock system for op-

erator safety. The safety interlock system requires the

parking brake to be engaged and the SDLA lever to be

in the neutral position for the power unit to start.

1. Turn the fuel shut-o valve to the On position.

2. Turn the battery disconnect switch to the On posi-

tion.

3. Pull out the choke handle to the choke or start

position. Choke may not be required when the

engine is at operating temperature.

4. Move the throttle lever to the fast idle position.

ATTENTION

Do not run the electric starter continuously for more

than 5 seconds. If the engine does not start in this

time, wait one minute and try again.

5. Turn the ignition key to the start position and hold

to engage the starter. Release the key when the

engine starts. NOTE: if engine fails to start, refer

to the troubleshooting section.

6. As the engine warms up, gradually push the choke

handle in to the run position. Wait until the engine

runs smoothly before each adjustment.

ATTENTION

Allow time for the hydraulic oil to circulate before

operating the power unit. Failure to allow adequate

warm up time may result in severe damage to the

hydraulic system. Warm up time is increased in

colder weather.

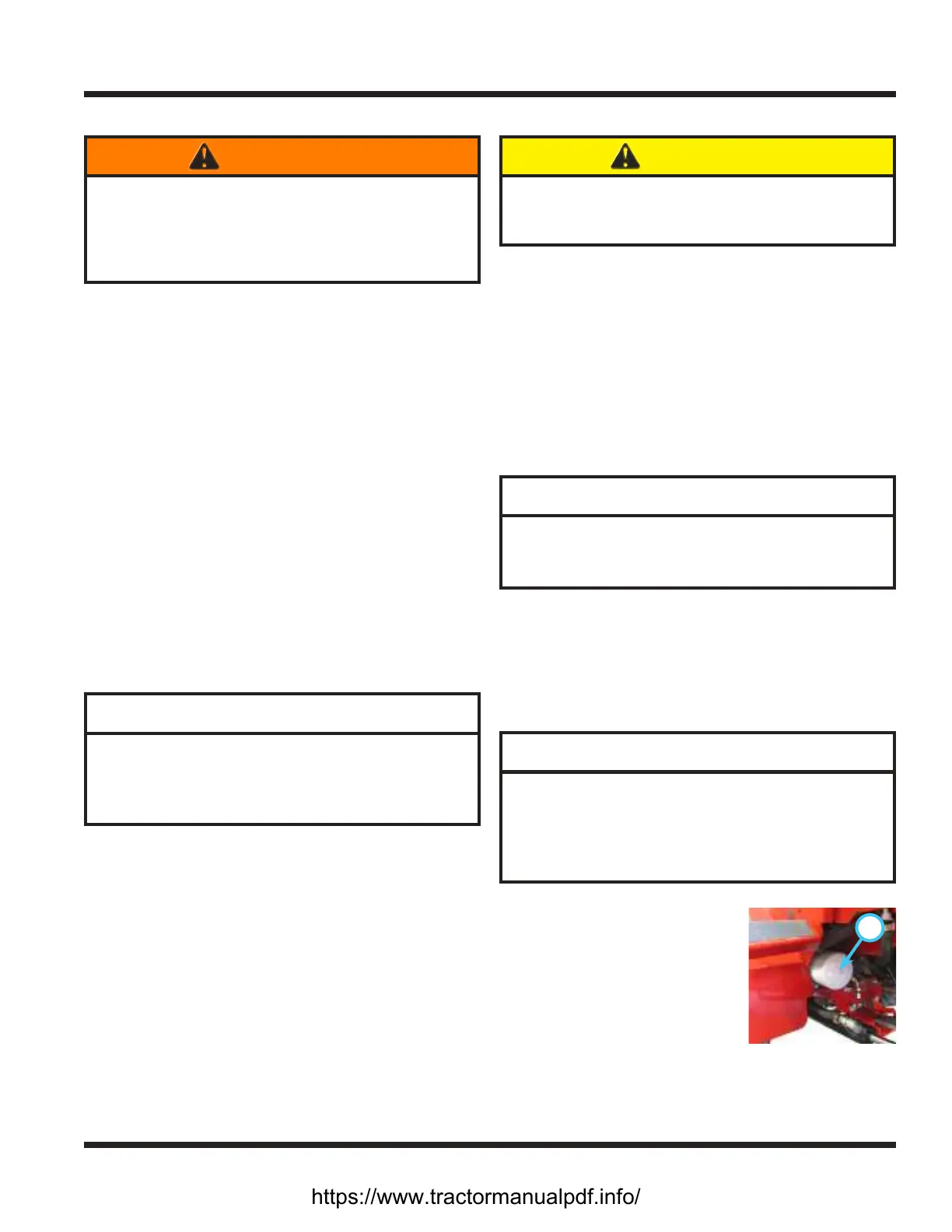

7.

A

The engine and hydraulic oil must be warmed up

before operating. Allow the

power unit to run at approxi-

mately 1,800 rpm until the

hydraulic lter is warm to the

touch. The lter (A) is located

to the inside of the left front

fender.

https://www.tractormanualpdf.info/

Loading...

Loading...