SERVICE

Service - 46

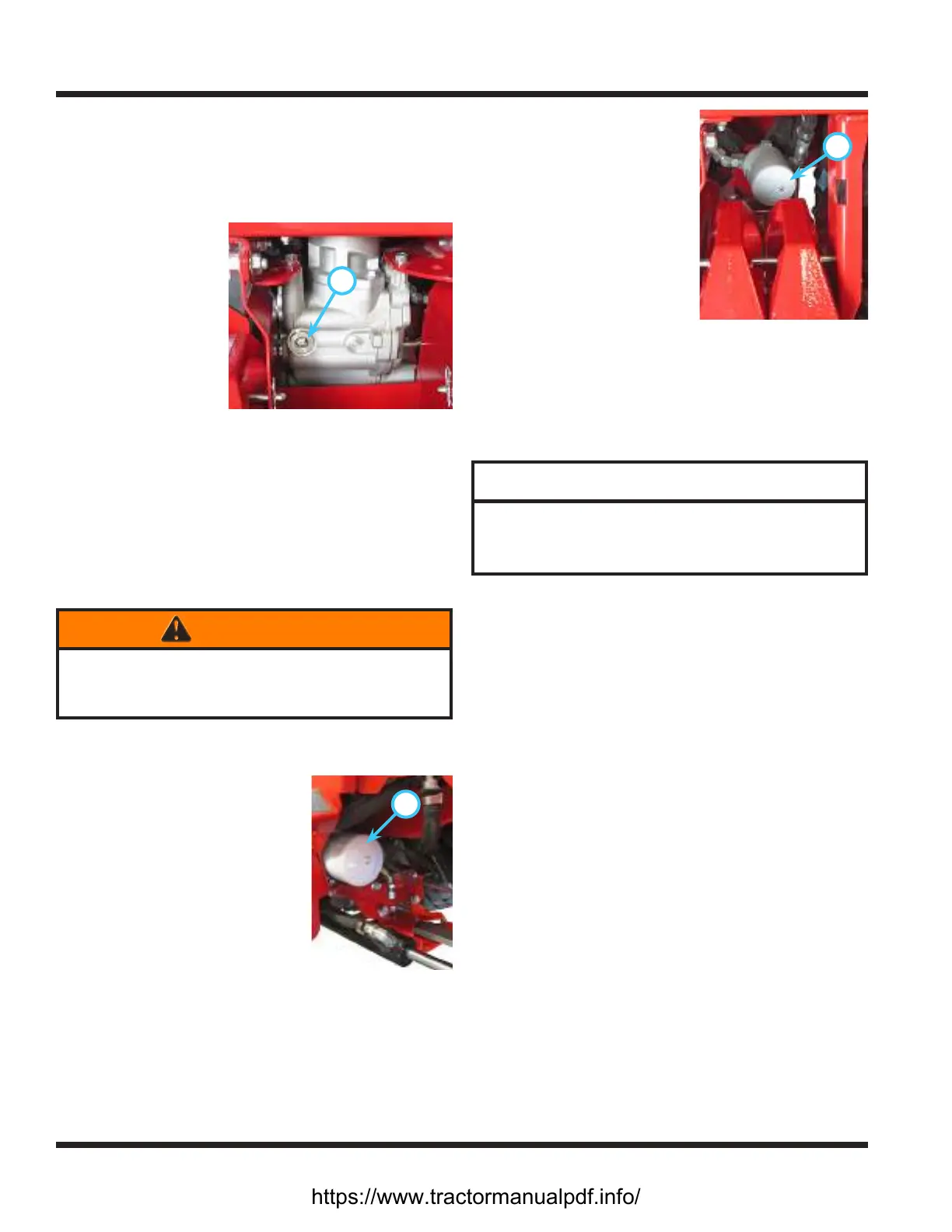

Checking the Rear Transaxle Oil

Check the rear transaxle oil level when the oil is cold,

prior to operating the power unit.

1. Remove the rear weights from the hitch bar (if

equipped).

A

2. Remove the oil

ll plug (A) from

the transaxle and

check to see if the

oil level is even

with the bottom of

the oil ll hole.

3. If the oil level is

low, add Hydro-

Torq XL synthetic

hydraulic oil until

the oil is level with the bottom of the oil ll hole.

4. Reinstall the plug into the rear transaxle and

torque to 34-39 Nm (25-29 ft-lbs).

5. Clean up any spilled oil.

6. Reinstall the rear weights (if equipped).

Changing the Hydraulic Oil Filters

1. If the power unit has been running, allow time for

the hydraulic system to cool.

WARNING

Hot oil can cause severe burns. Allow the oil tem-

perature to drop from hot to warm before changing

the oil lters.

2. Remove the hydraulic lter access cover.

3. Clean the hydraulic lters, the lter heads, and the

area around the lters.

A

4. Place a drain pan (minimum

3.8 liter / 4 quart) under the

large hydraulic lter (A) in

front of the left foot platform.

5. Use a strap type lter wrench

to unscrew the lter from the

lter head and allow the oil to

drain into the pan.

6. Wipe the lter mounting sur-

face with a clean cloth.

7. Apply a thin lm of clean oil to the gasket of the

new lter and screw onto the lter head until the

gasket makes contact with the mounting surface.

Tighten the lter an additional 3/4 of a turn (may

require using a strap type lter wrench).

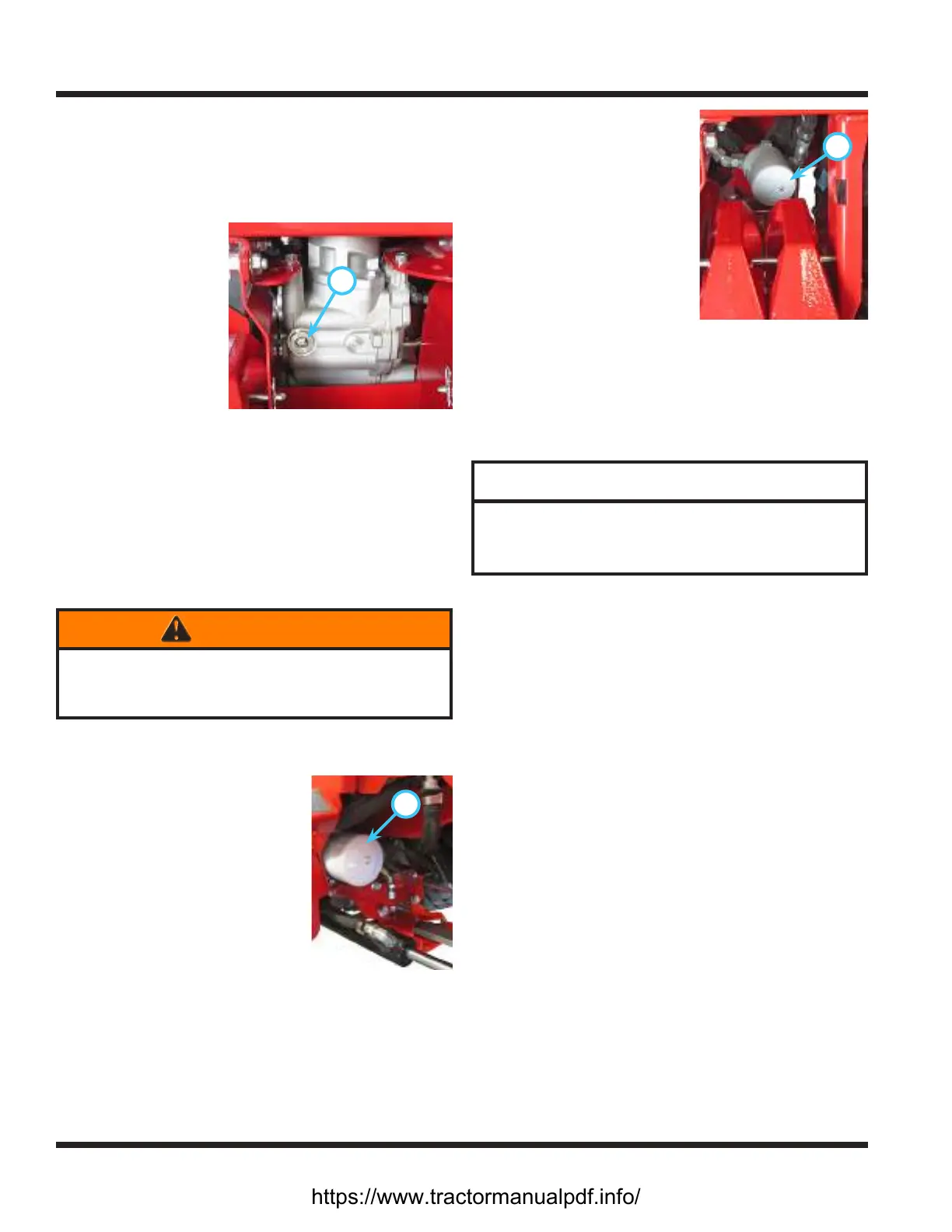

8. Place the drain pan

B

under the right rear axle

beneath the small hydrau-

lic lter (B).

9. Use a strap type lter

wrench to unscrew the

lter from the lter head

and allow the oil to drain

into the pan.

10. Wipe the lter mounting

surface with a clean cloth.

11. Apply a thin lm of clean oil to the gasket of the

new lter and screw onto the lter head until the

gasket makes contact with the mounting surface.

Tighten the lter an additional 1 turn (may require

using a strap type lter wrench).

12. Clean up any spilled oil and dispose of oil and

lters in accordance with local laws.

ATTENTION

Oil is hazardous to the environment. Drain oil into

an approved container and dispose of used oil in

accordance with local laws.

13. If the hydraulic oil is being changed at the same

time as the lters, skip the remaining steps and

proceed to the Changing the Hydraulic Oil section.

14. Add HydroTorq XL synthetic hydraulic oil to the

hydraulic oil tank until the oil level in the plastic

sight tube is within the proper range indicated by

the oil level decal.

15. Start the power unit and let it run at low idle

engine speed for a few minutes. Turn the steer-

ing wheel to the left and right a couple of times to

purge any trapped air out of the hydraulic system.

16. Shut o the power unit engine and allow the

power unit to sit for a minimum of ve minutes.

17. Check the hydraulic oil level. Refer to the Checking

the Hydraulic Oil Level section.

18. Inspect both of the hydraulic lters for signs of

leakage. If any leaks are evident, the lter may

need tightened further, or the lter may need to

be removed, the gasket and lter mount cleaned,

and the lter reinstalled following the procedures

for changing the lter.

19. Reinstall the hydraulic lter access cover.

https://www.tractormanualpdf.info/

Loading...

Loading...