MECHANICAL INSTALLATION

7 B001686

INSTALLATION WITH SPINLOCK

Conventional assembly. (Instrument is put into the drill hole from the front).

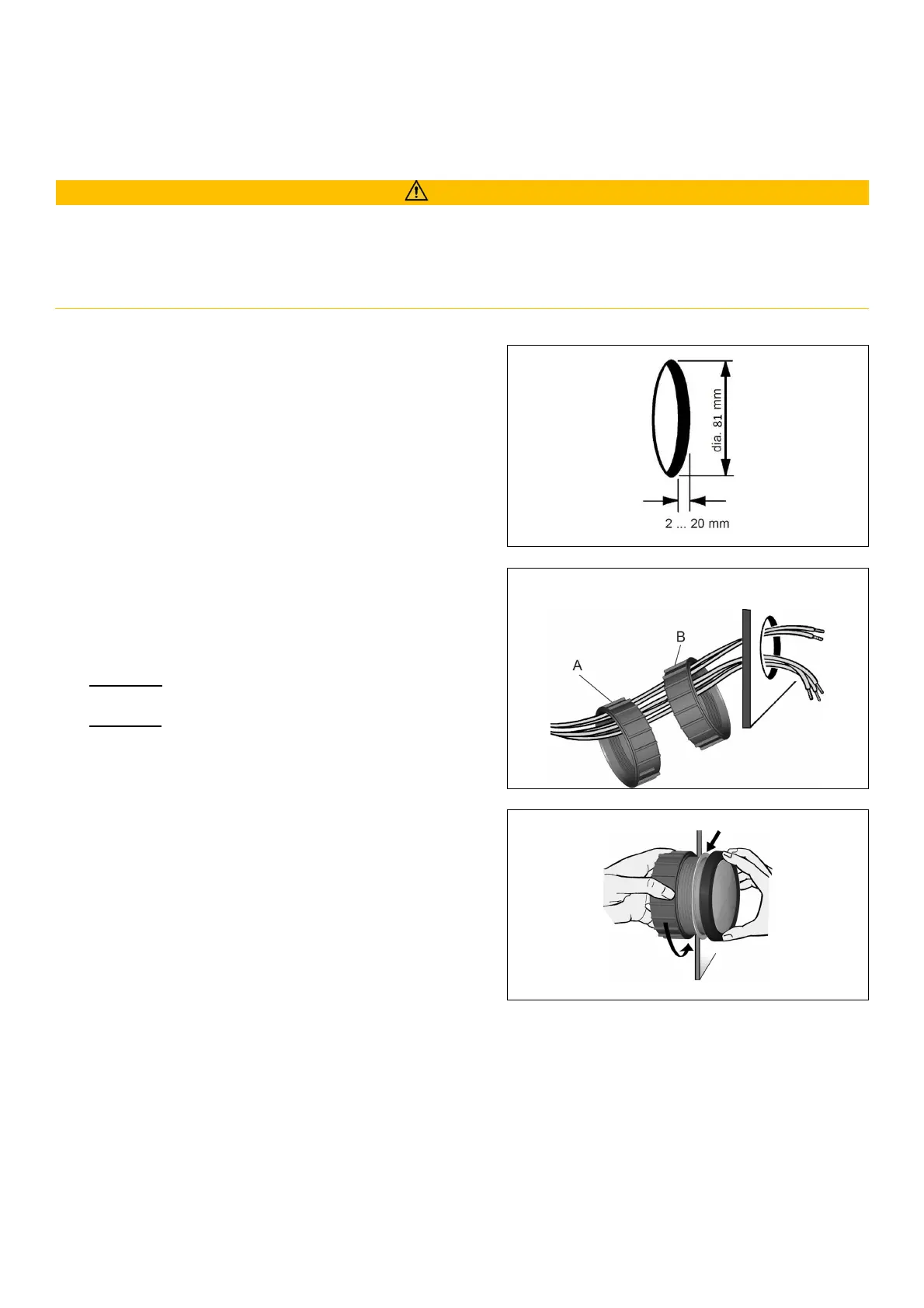

The panel thickness may be within a range of 2 to 18 mm.

The drill hole must have a diameter of 81 to 86 mm.

WARNING

• Do not drill holes or ports in load-bearing or stabilizing stays or tie bars!

• Note the necessary clearance behind the drill hole or port at the installation location. Required

mounting depth: 65 mm.

• Drill small ports; enlarge and complete them, if necessary, using taper milling tools, saber saws, keyhole

saws or files. Deburr edges. Follow the safety instructions of the tool manufacturer.

1. Create a circular hole in the panel considering the

device dimensions.

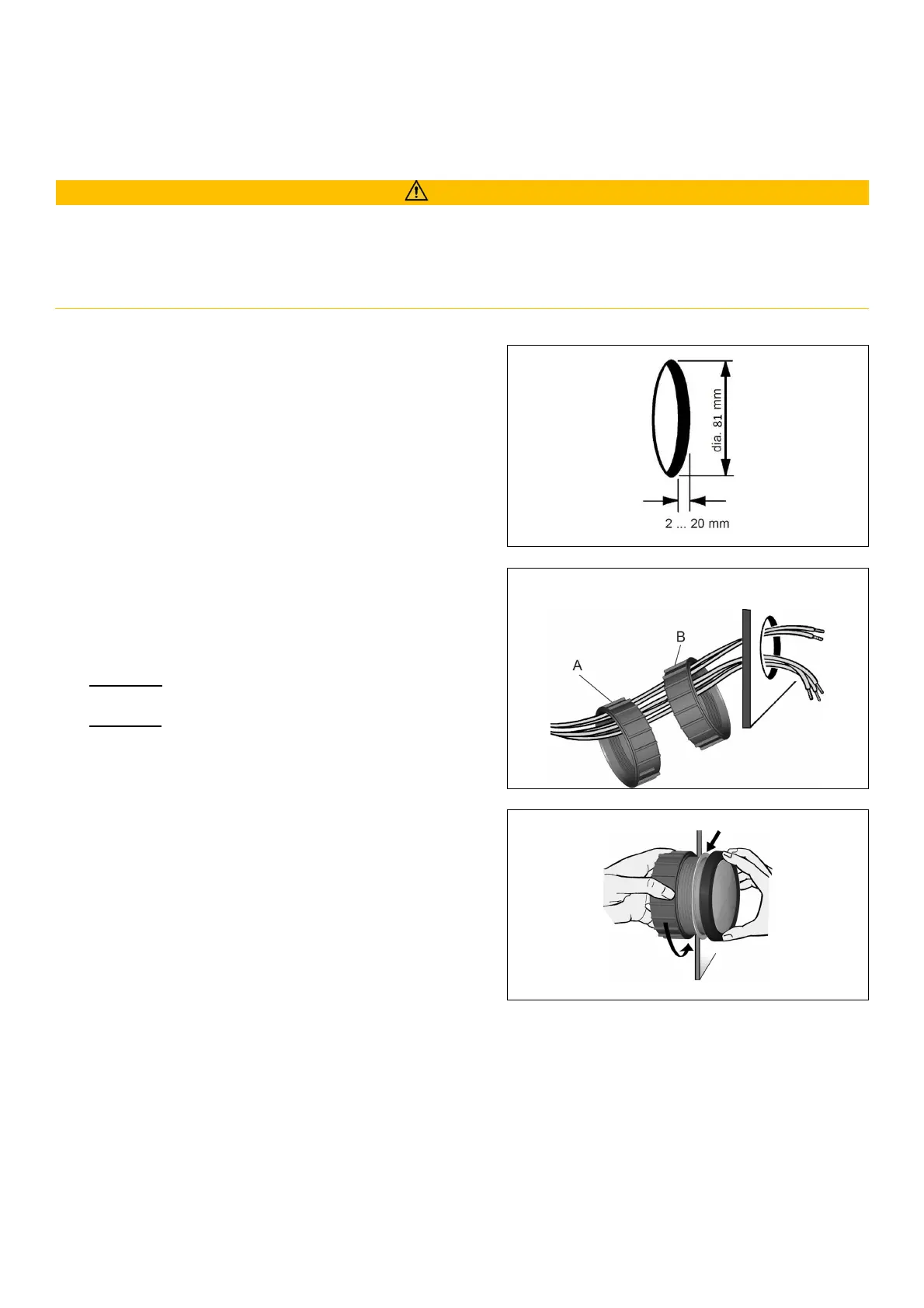

2. Remove the spinlock and insert the device from

the front.

3. For 85 mm instruments, the fastening nut can be

mounted at position A or B. This allows you to fix

the gauge in different panel bores.

Version A

Panel bore 80.5 – 81 mm

Version B

Panel bore 85.5 – 86 mm

4. Align the instrument and hand-tighten the

fastening nut. Ensure that the nut is not tightened

with a torque greater than 4 Nm.

5. Make sure the seal lays flat between the panel and

the front ring.

Loading...

Loading...