16

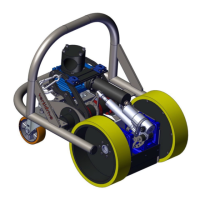

M7 – 11.607

User manual

www.vertidrive.nl

Before starting

o Always perform a LMRA in following three steps:

Recognizing potential dangers that could be present despite all the measures taken.

Employees should first ask themselves if they are risking exposure to these dangers.

They must not start the work if they believe the risks are unacceptable.

Thinking up solutions or measures to remove the perceived risks or make them

acceptable

Taking measures to let them carry out the work activities safely. The employee

carries out the required control measures to eliminate or control the dangers. If

necessary, they should ask for help in achieving this.

An LMRA never stops. It is a continuous awareness of the steps prior to perform a task

or follow a procedure.

o Always secure the robot against falling with appropriate and certified fall arrest equipment.

When the robot does fall it is possible it will hit other objects, obstacles or humans. Any consequent

damage, injuries or cost resulting from inappropriate use and/or falling of the robot is NOT the

responsibility of VertiDrive. VertiDrive cannot be held liable for damages, injuries or costs resulting from

inappropriate use.

o Prior to usage, mark an area- with yellow/black ribbon to ensure a distance to robot of at least 6

meters. This area should not be entered without the permission of the operator.

o Ensure proper warnings by placing visual signage where necessary.

o Caution should be taken when plugging and unplugging the power supply. Appropriate and

approved power cables should be used.

o Prior to use of the VertiDrive M7 Robot, the user/operator must perform a check, see “General

Checklist start-up procedure”. Initial training of users/operators is provided by VertiDrive and or

VertiDrive certified representatives/trainers, upon delivery of a new robot.

o When additional equipment is installed on the robot the operator should be certified and or trained

to use this additional equipment.

o When using UHP equipment extra care should be taken on how to use this equipment and all

safety precautions should be taken and respected.

o Attached equipment such as UHP or blasting equipment will make noise. Always use appropriate

hearing protection.

The robot itself produces a low humming sound when only driving.

o To decrease the weight to be carried by the robot, the power cables and vacuum hose can be

attached to the winch safety line. Ensure that the safety lines can travel freely to their new

position. Ensure cables and hoses are in the correct position in relation to the robot.

During operation

o Always keep visual contact with the robot during usage.

o Never stand underneath the robot!!

Be aware: If robot falls it may swing towards the operator and or other people in the vicinity.

o Always use protective clothing and use appropriated facial protection.

o Prior to approaching the robot or when in close vicinity make sure the power is turned off by

pushing the red emergency stop button on the control box.

o When the robot is NOT in use always unplug the main power supply.

o Do not distract operator while operating.

o Keep at least 6 meters away from the robot during operation.

o Always pay attention for slack of rope/hoses on the floor, the operator might caught by, or stumble

over the hoses with risk of injuries.

During maintenance/service:

o Always unplug the main power supply.

o When working on the robot extra caution should be taken to avoid direct contact between steel

tools and the magnets. Magnets are very strong and can cause injuries. The magnets will also

affect sensitive electronic and mechanic equipment like cell-phones, watches and (bank) cards

with magnetic strips.

Loading...

Loading...