Service Manual Indicator JIK-6 Page 19

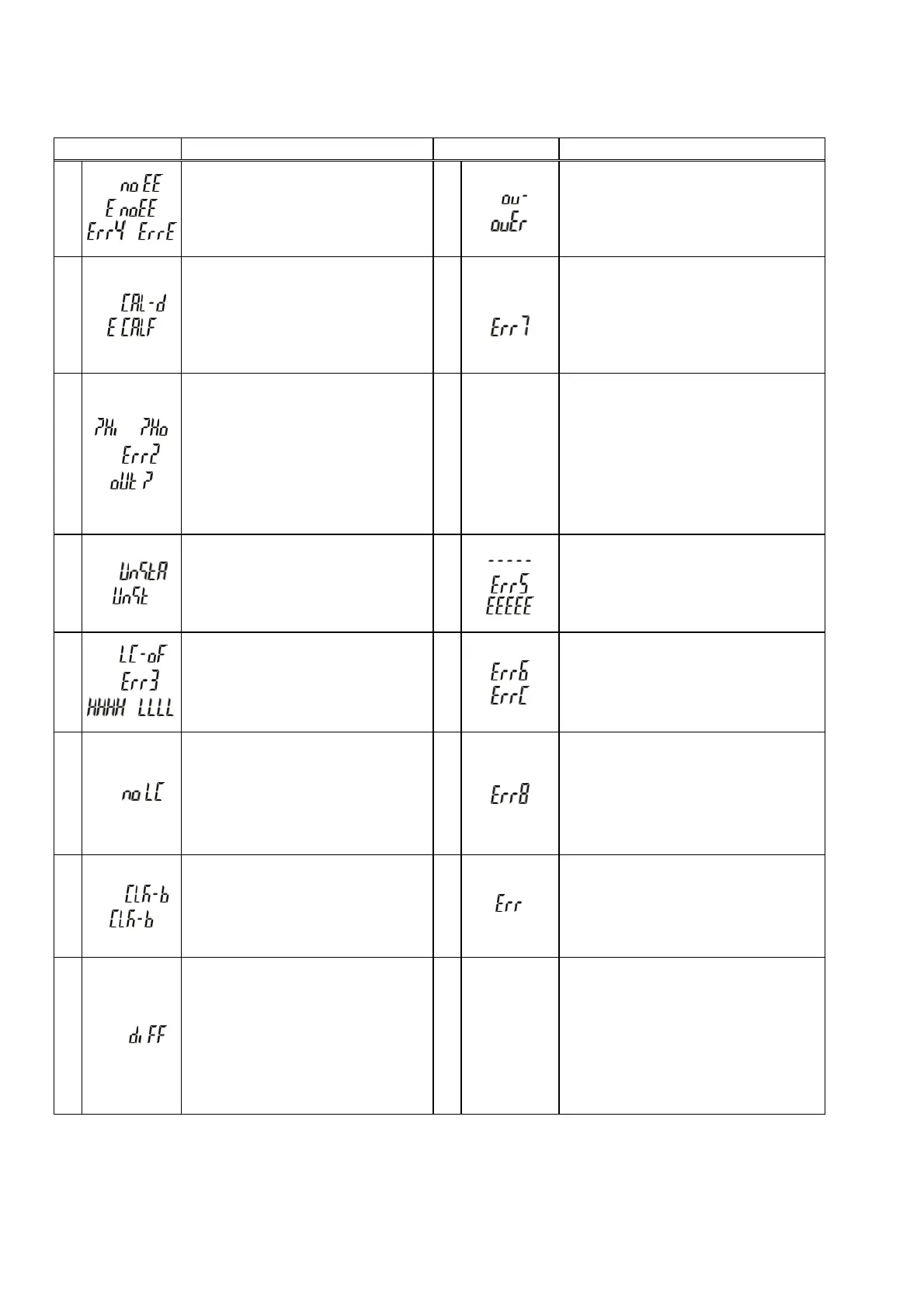

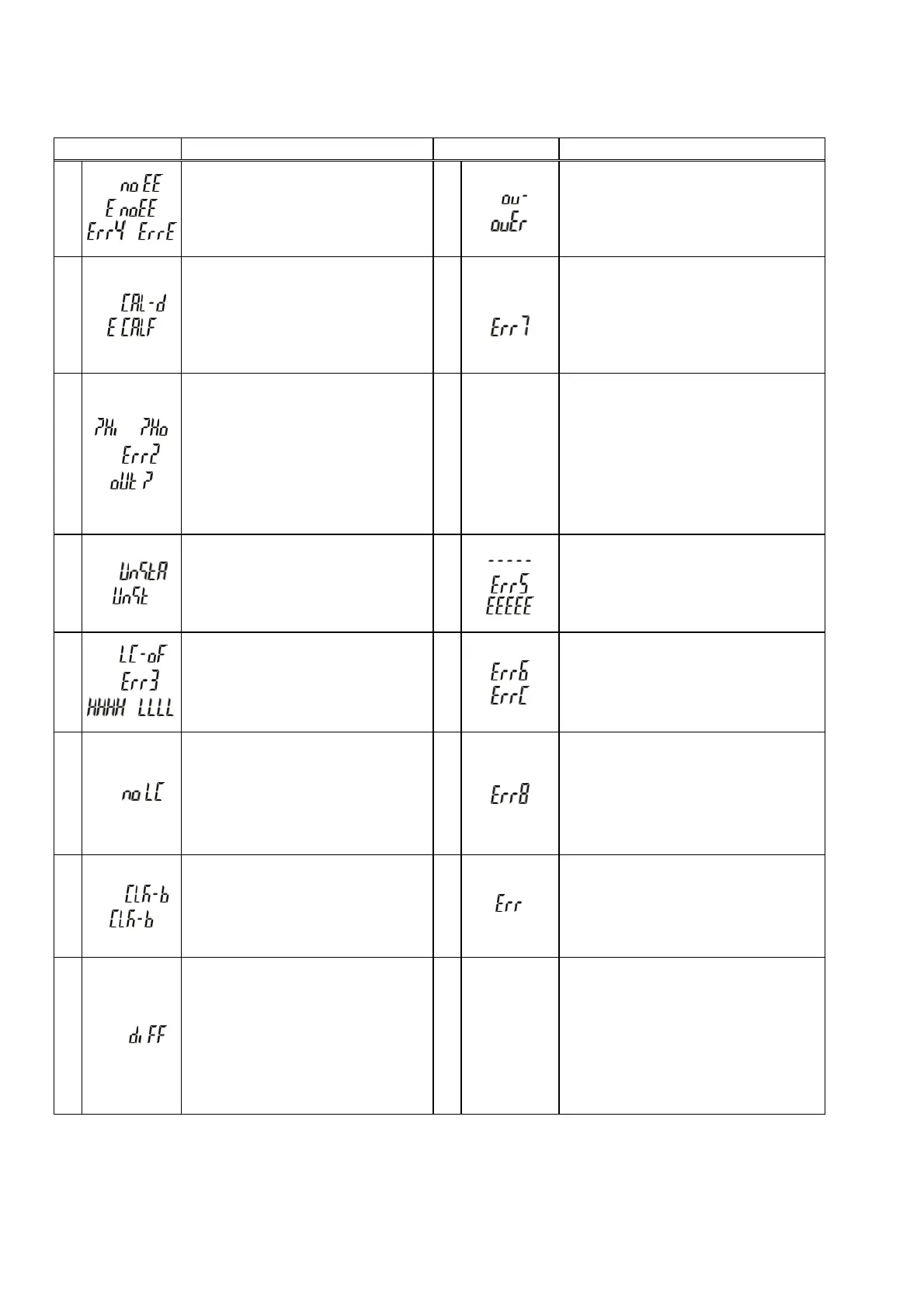

4-3 Summary Table of Error Message

Including the full range of China-made models and Taiwan-made JIK, JC (W) A, JP (W) G, and the

new versions SNUG, NWTC, JKD and JKH.

Error Message Possible Cause Error Message

Possible Cause

1

E0

or

Memory IC defect.

CPU lead welding defect.

No internal

setting/calibration

data.

9

E12

XX

The accumulation group number

has exceeded the max. Preset

value.

2

E1

Calibration setting error.

10

E20 XXXX

This message appears when

precision setting exceeds the

standard, e.g. the original max.

Precision setting value is 1/30000,

but the input setting value exceeds

this precision setting.

3

or

±

Initial zero point value over

standard.

Weighing pan is not clear, or

there is interference of unknown

object.

Interference of transportation or

overload protection screw.

11 E21 XX

Based on OIML standard,

this

appears when the basic model’s e

resolution ratio is <100, or when the

advanced model’s e resolution ratio

is <1

50.

4

E4

Zero point can’t be detected due

to environment interference

L/C defect.

Board defect.

12

Exceeding max. Weighing capacity.

(Full load weight +9e)

5

E5

±

or

L/C specification goes beyond the

handling range of ADC.

L/C may have been damaged.

Calibration data setting error.

13

Weight value being used not

conforming to calibration value

requirement when performing

calibration.

6

E6

No L/C signal or L/C not

connected.

L/C line damaged or brok

en.

Bad contact of metal connector.

(Platform scale)

14

Unit being used conflicts with initial

unit setting, e.g. when setting all

units usable when power on at OFF.

7

E10

RTC battery defect or battery not

installed.

RTC board defect.

RTC time not set.

15

Beyond the display range of LCD

window.

8

E11

In accu

mulation mode, on

ly one

fixed unit can be used at one time,

or in the case of dual weighing

pans, accumulation is to be

performed in another group when

one group has accumulation

function alread

y.

17

Loading...

Loading...