8.15 Cleaning the cooling liquid sys-

tem

If the flow rate of the cooling liquid isn’t sufficient or

the corresponding interval in the maintenance table

has been exceeded, you must clean the cooling liquid

system.

The task consist of the following automated processes:

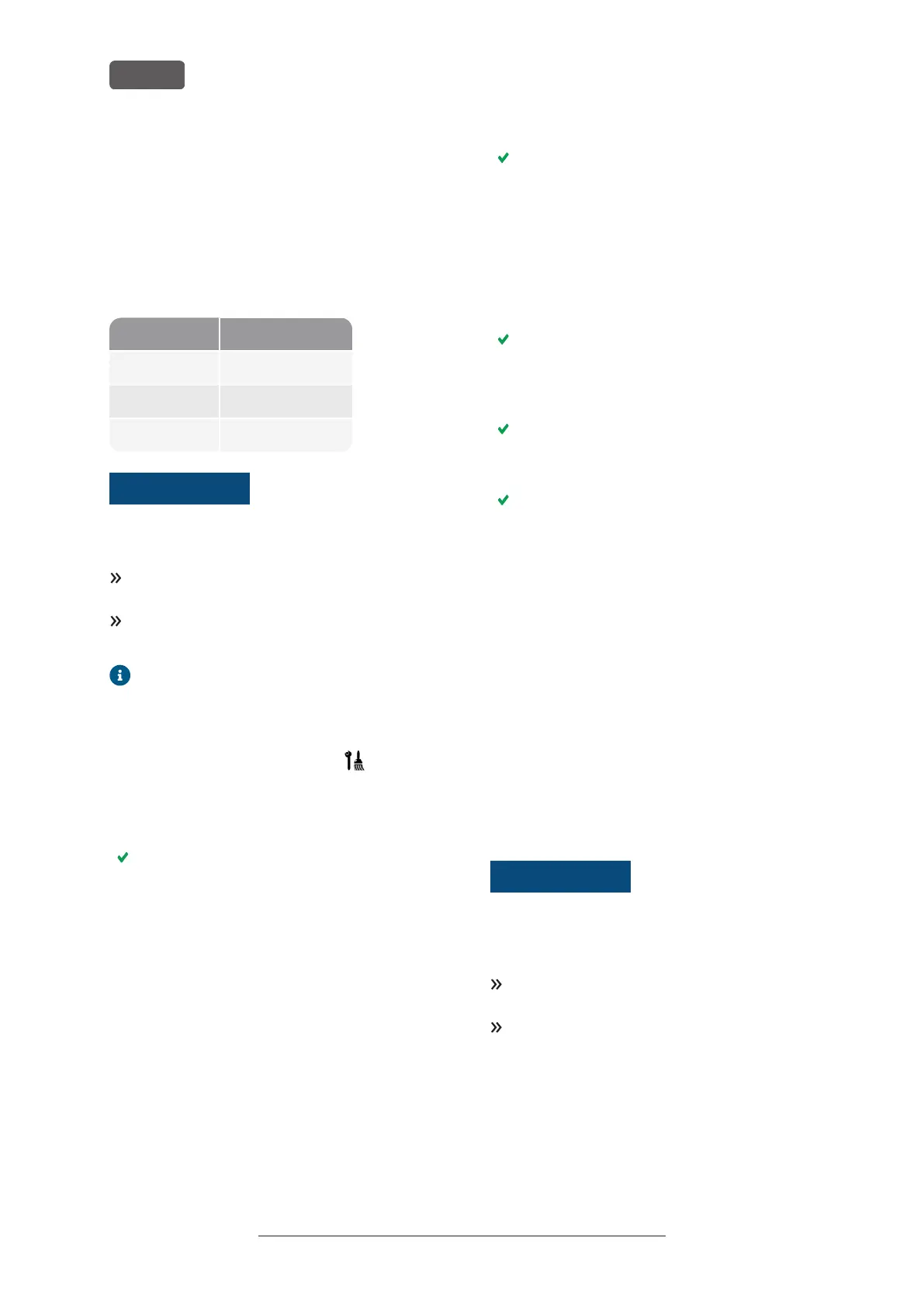

Process Duration (approx.)

Cleaning 30minutes

Rinsing 5minutes

Drying (optional) 15minutes

NOTICE

Material damage when

cleaning the cooling liquid

system incorrectly

If you clean the cooling liquid system incorrectly, the

machine, blanks and tools will be damaged.

Only use Tec Powder from vhf to clean the cooling

liquid system.

Carefully follow the instructions below.

Tec Powder is available from customer service.

1. Start DENTALCNC.

2. Open the Maintenance section window with the fol-

lowing icon in the main iconbar:

3. Select the Cleaning the cooling liquid system main-

tenance task.

4. Confirm the current message.

The on-screen guide displays.

5. Confirm the opening of the working chamber door

and multi-purpose compartment.

6. Remove the following items from the working

chamber:

n

Any blank and holder

n

The tool magazine

7. Perform a weekly cleaning of the working chamber.

Cleaning the working chamber – on page53

8. Empty and clean the cooling liquid tank.

9. Fill 2l (2.1qt) of drinking water without cooling lub-

ricant into the tank.

10. Add 50g Tec Powder to the water. Stir the water

until the powder is completely dissolved.

11. Insert the tank into the machine.

12. Go to the next step of the on-screen guide.

The cleaning process starts. The remaining time dis-

plays in the info area of DENTALCNC‘s main applic-

ation window.

13. Wait until the process is finished.

14. Empty the cooling liquid tank. Refill it with drinking

water without cooling lubricant.

15. Insert the tank into the machine.

16. Go to the next step of the on-screen guide.

The rinsing process starts. The remaining time dis-

plays in the info area of DENTALCNC‘s main applic-

ation window.

17. Wait until the process is finished.

DENTALCNC asks you if the machine should dry the

working chamber.

18. Select the desired option.

If selected, the drying process starts. The remaining

time displays in the info area of DENTALCNC‘s main

application window.

19. Wait until the process is finished.

20. If you didn’t select the drying process, dry the work-

ing chamber with a cloth.

21. Empty the cooling liquid tank.

22. Exchange the carbon filter. Exchanging the carbon

filter – on page61

23. Thoroughly clean the cooling liquid tank.

24. Fill in cooling liquid for processing. Exchanging

the cooling liquid and cleaning the tank – on page33

25. Insert the tool magazine into the working chamber.

8.16 Checking the compressed air

regulator

NOTICE

Damaging of the machine

when compressed air is

contaminated

Compressed air that does not fulfill the guidelines for

purity according to ISO 8573-1 can damage the

machine.

Check the water separator of the compressed air reg-

ulator daily for contamination.

Never use the machine if there is water, oil or solid

particles in the water separator.

8.16.1 Checking the w ater separator for con-

densate

Condensate in the separator usually points to

compressed air not being dry enough.

Original Operating Instructions:R5

Version: 12/16/2021

R5 – Maintenance and do-it-yourself

EN 66

Loading...

Loading...