INSTALLING THE COVER PLATE GASKET AND COVER PLATE

CAUTION

• Use only Victaulic-supplied replacement parts.

Failure to follow this instruction could cause improper valve opera-

tion, resulting in property damage.

1. Verify that the cover plate gasket is in good condition. If the gasket

is torn or worn, replace it with a new, Victaulic-supplied gasket.

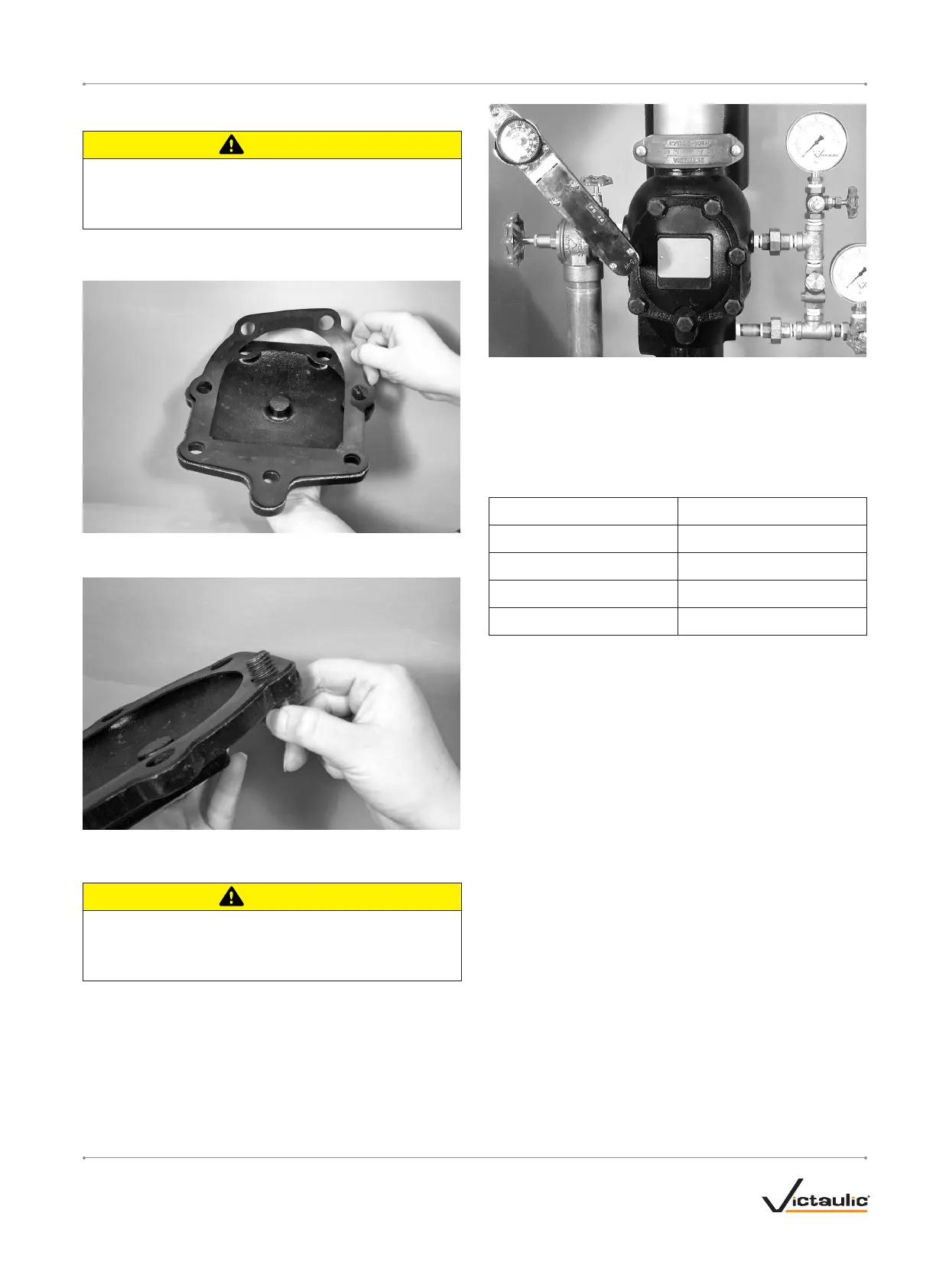

2. Align the holes of the cover plate gasket with the holes in the cover

plate.

3. Insert one cover plate bolt through the cover plate and cover plate

gasket to ease alignment.

CAUTION

• DO NOT over-tighten the cover plate bolts.

Failure to follow this instruction could cause damage to the cover

plate gasket, resulting in valve leakage.

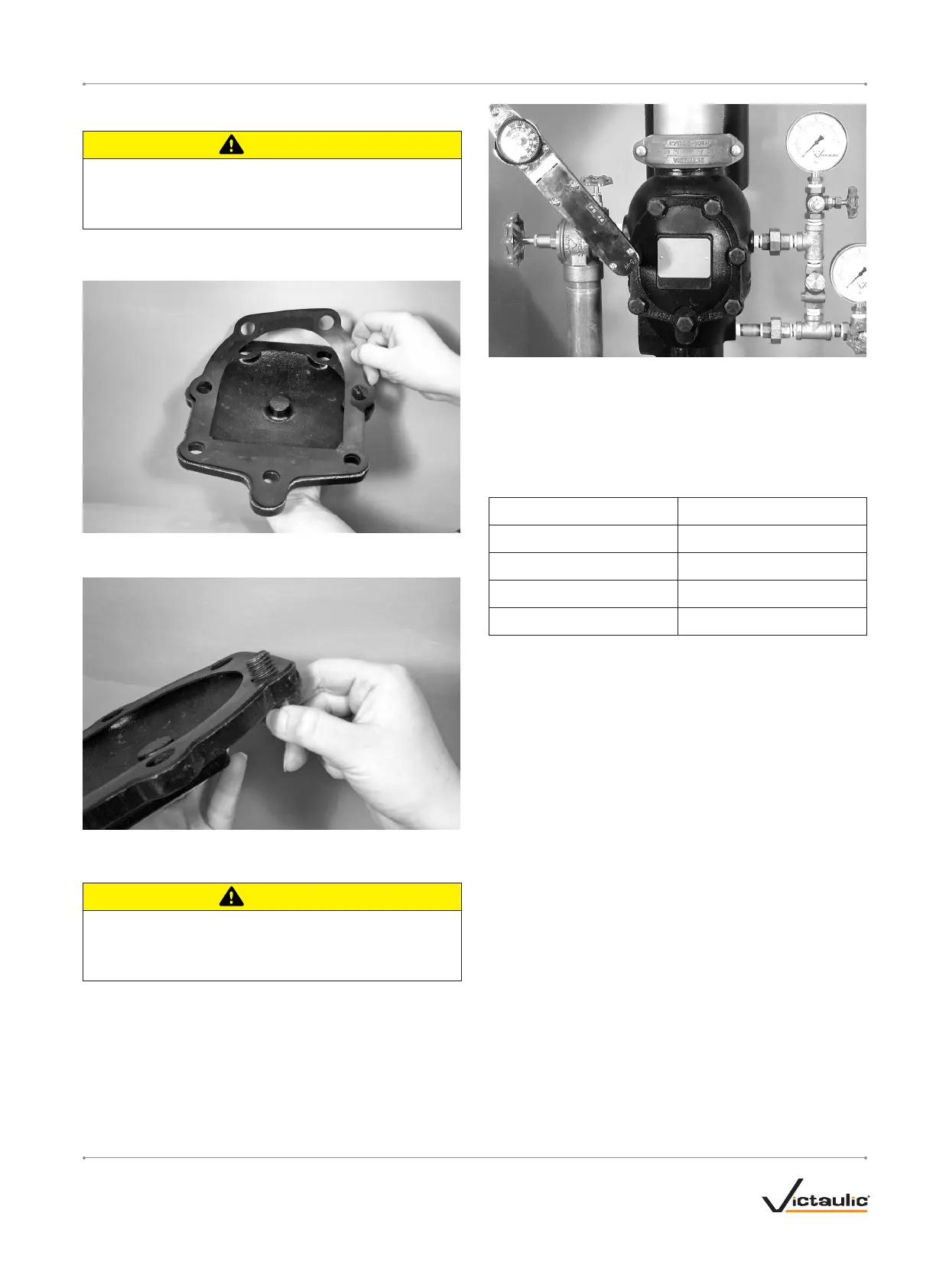

4. Align the cover plate/cover plate gasket to the valve. Make sure the

clapper spring’s arms are rotated to their installed position. Tighten

all cover plate bolts into the cover plate/valve body.

4a. Torque all cover plate bolts in an even, crossing pattern. Refer

to the “Required Cover Plate Bolt Torques” table below for the

required torque values. DO NOT over-tighten the cover plate bolts.

REQUIRED COVER PLATE BOLT TORQUES

Size Torque N•m

DN80

81

DN100

136

DN150

156

DN200

136

5. Place the system back in service by following the “Placing the

System in Service” section.

I-751.VDS / Series 751 FireLock

™

European Alarm Check Valve Stations / Installation, Maintenance, and Testing Manual

I-751.VDS_19REV_F

Loading...

Loading...