IMPORTANT INSTALLATION INFORMATION

1. For proper operation and approval, the Series 751 FireLock Alarm

Check Valve must be installed in accordance with the specific trim

diagrams included with the shipment.

2. Before installing the Series 751 FireLock Alarm Check Valve, flush

the water supply piping thoroughly to remove all foreign material.

3. Series 751 FireLock Alarm Check Valves MUST NOT be located in

an area where the valve can be exposed to freezing temperatures.

In addition, the Series 751 FireLock Alarm Check Valve MUST

NOT be located in an area where physical damage may occur.

4. It is the system designer’s responsibility to confirm material com-

patibility of the Series 751 FireLock Alarm Check Valve, trim, and

associated accessories when a corrosive environment or contami-

nated water is present.

5. SERIES 751 FIRELOCK ALARM CHECK VALVES MUST BE

INSTALLED ONLY IN THE VERTICAL POSITION WITH THE

ARROW ON THE BODY POINTING UPWARD. THE ARROW ON

THE SWING CHECK VALVE IN THE BYPASS LINE MUST POINT

UPWARD.

6. The Victaulic Series 752 VdS Retarding Chamber Assembly should

be installed in variable pressure applications. NOTE: Victaulic pro-

vides specific trim drawings for installations that involve a Series

752 VdS Retarding Chamber Assembly.

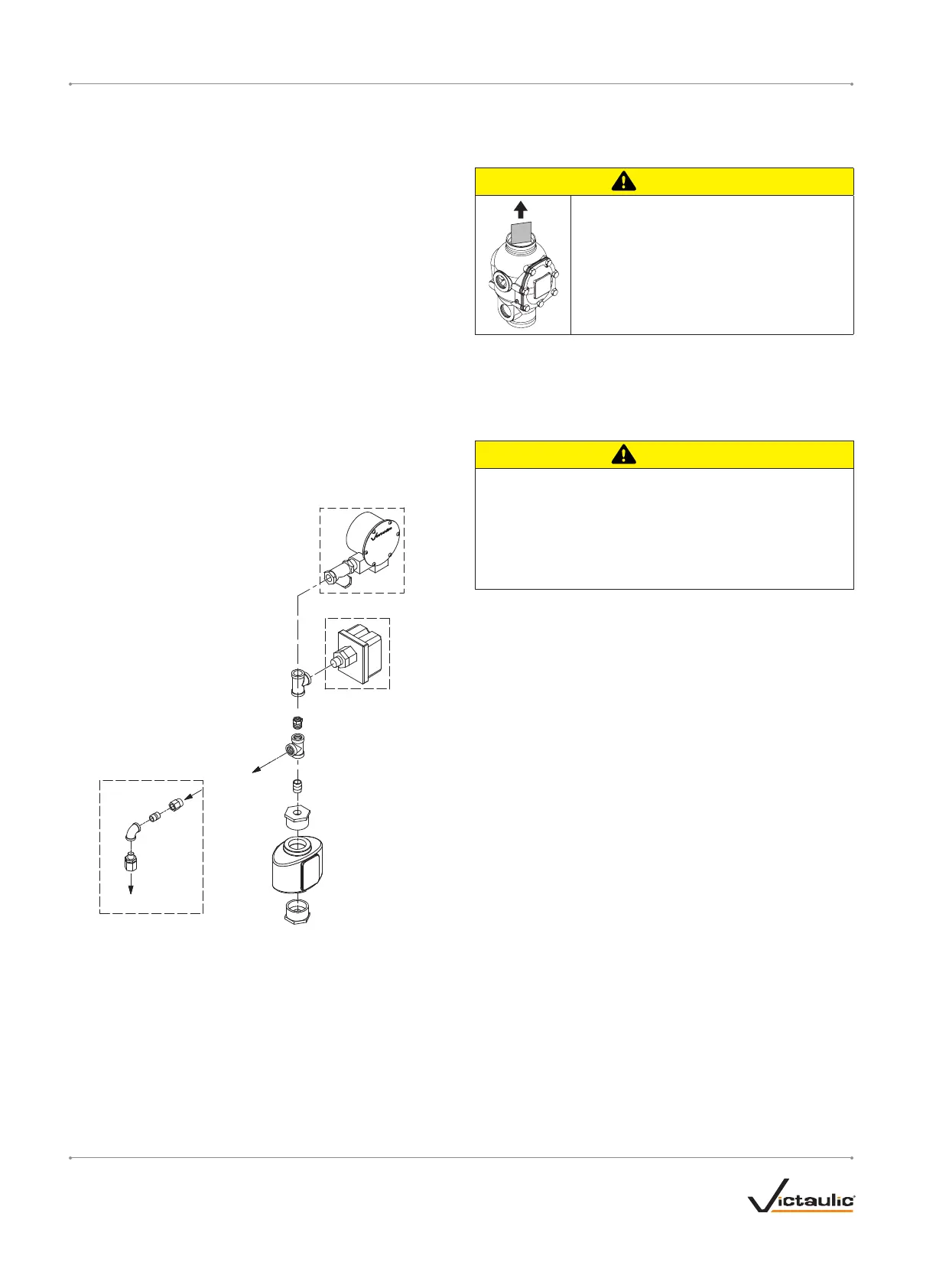

Optional Series 752V

Retard Vent Kit

To Water Motor

Alarm or Optional

Series 752V Retard

Vent Kit

Pipe to

Open Drain

Optional Alarm

Pressure Switch

Optional Series 760 European

Water Motor Alarm Assembly

6a. The Series 752V Retard Vent Kit is required any time an air break

is needed above the Series 752 VdS Retarding Chamber Assembly.

In addition, the Series 752V Retard Vent Kit is required if multiple

valves are tied into one water motor alarm and a check valve iso-

lates each line. Refer to the drawing above.

7. When the Series 751 FireLock Alarm Check Valve is used with a

water motor alarm, an uninterrupted alarm pressure switch is rec-

ommended in the location shown in the drawing above.

VALVE/TRIM INSTALLATION

1. Make sure trim drawings match system requirements.

CAUTION

• Make sure the foam spacer is removed from

inside the valve body before attempting to

install the valve.

Failure to follow this instruction could cause

improper valve operation, resulting in personal

injury and/or property damage.

2. Remove all plastic caps and foam spacers from the valve.

3. Apply a small amount of pipe joint compound or PTFE thread

sealant tape to the external threads of all threaded pipe

connections. DO NOT get any tape, compound, or other foreign

material into the valve body, pipe nipples, or valve openings.

CAUTION

• Make sure no foreign material gets into the valve body, pipe

nipples, or valve openings.

• If using any material other than PTFE thread sealant tape, use

extra caution so that no material gets into the trim.

Failure to follow these instructions could cause improper valve

operation, resulting in personal injury and/or property damage.

4. Install the valve, trim, and accessories per the trim drawing.

HYDROSTATIC TESTING

The Victaulic Series 751 European Alarm Check Valve is manufactured

and listed for a maximum working pressure of 16 Bar and is factory

tested to 41 Bar. The station can by hydrostatically tested against

the clapper at 14 Bar and/or 3.5 Bar above the normal water supply

pressure (2-hour limited time period) for acceptance by the authority

having jurisdiction.

I-751.VDS / Series 751 FireLock

™

European Alarm Check Valve Stations / Installation, Maintenance, and Testing Manual

I-751.VDS_6 REV_F

Loading...

Loading...