Vitodens 200-W B2HA 80 to 100, 285 to 352 Installation

5685 827 - 14

30

Boiler Connections

Waterside flow (primary circuit)

The Vitodens 200-W, B2HA is designed for closed loop,

forced circulation hot water heating systems only.

Use standard friction loss method for pipe sizing. Observe

boiler maximum and minimum flow rate limitations.

If system flow rate exceeds boiler maximum flow rate

(as stated above), falls below the minimum flow rate

or if system flow rate is unknown, Viessmann strongly

recommends the installation of a low-loss header.

Safety Connections (continued)

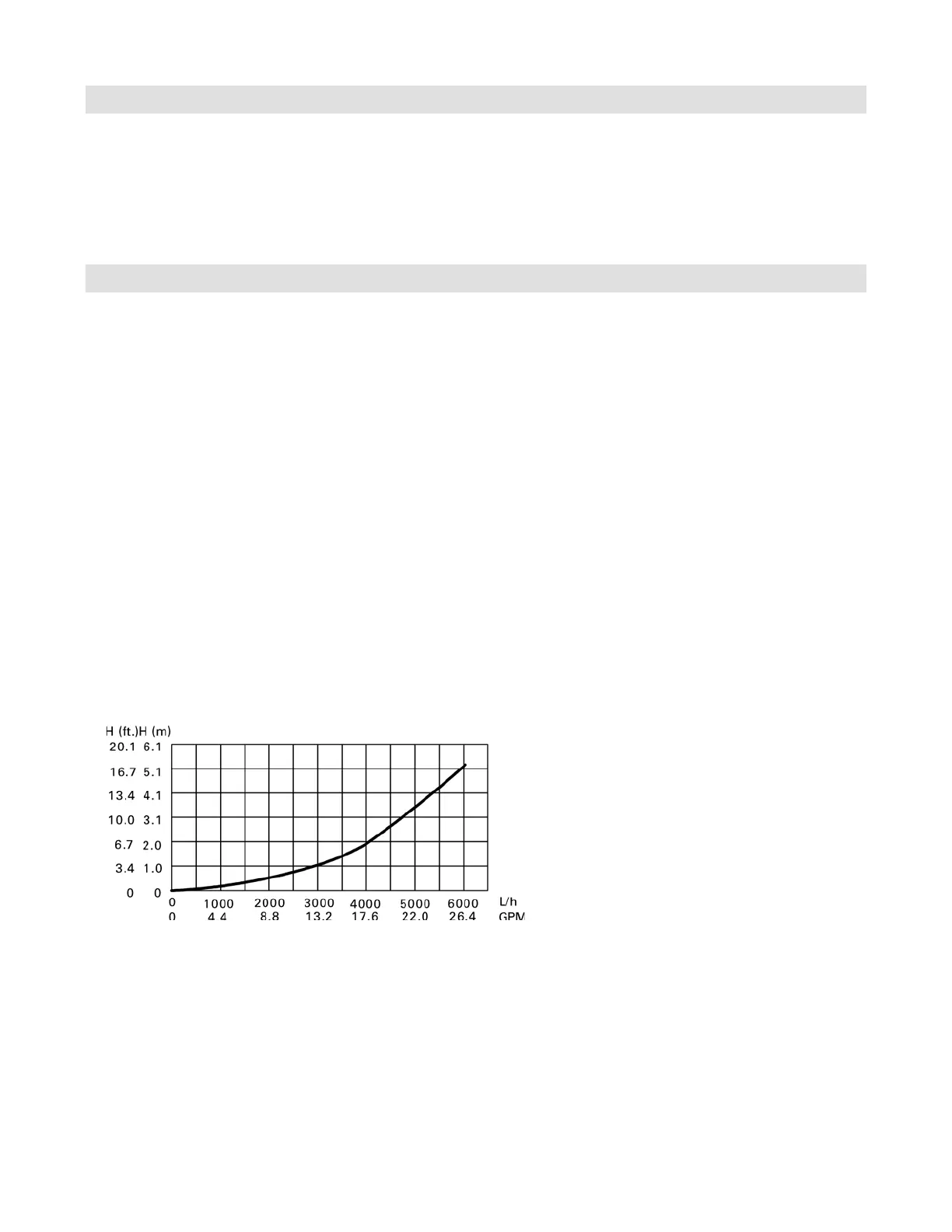

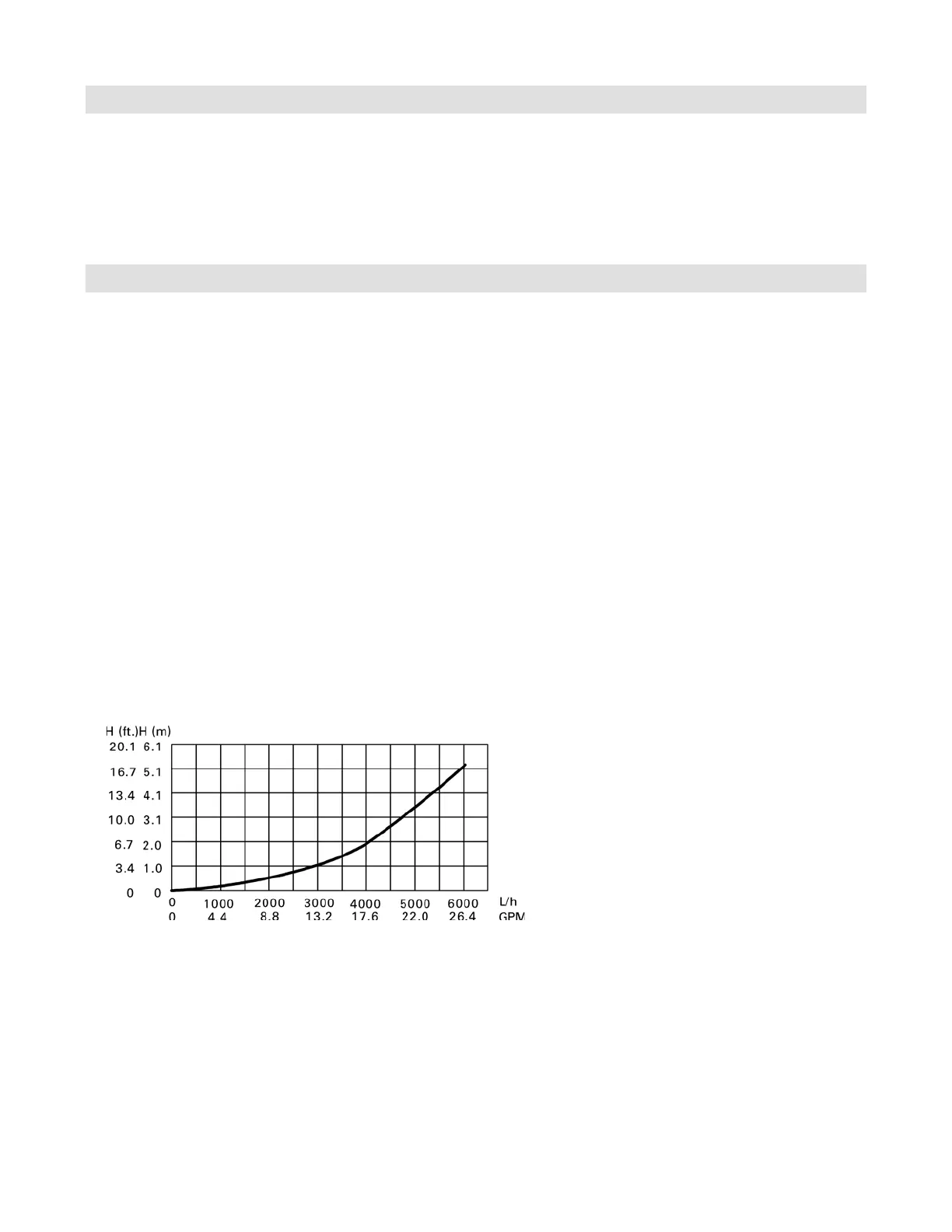

Waterside Flow

Supply head pressure (water)

Flow rate

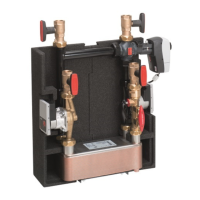

Once the low-loss header is connected, the built-in low-

loss header logic of the Vitodens 200-W boiler ensures

the required t across the system through the sensory

communication between the low-loss header and the

boiler.

An alternative method may be used, such as primary

secondary piping using closely spaced tees. A low-loss

header offers additional benefits not provided by a pair

of closely spaced tees. Viessmann therefore strongly

recommends and prefers the use of a low-loss header

over closely spaced tees. Refer to the Technical Data

manual for low-loss header information.

Pressure drop (primary circuit) for:

Vitodens 200-W, B2HA 80, 88, 100, 285, 311, 352

For sizing an on-site circulation system.

Max. flow rate 25 USGPM (5700 L/h)

Low water cut-off

A low water cut-off device may be required by local codes.

If required, a low water cut-off device of an approved type

(field supplied), is to be installed as per the manufacturers

instructions. DO NOT install an isolation valve between the

boiler and the low water cut-off device.

Loading...

Loading...