39

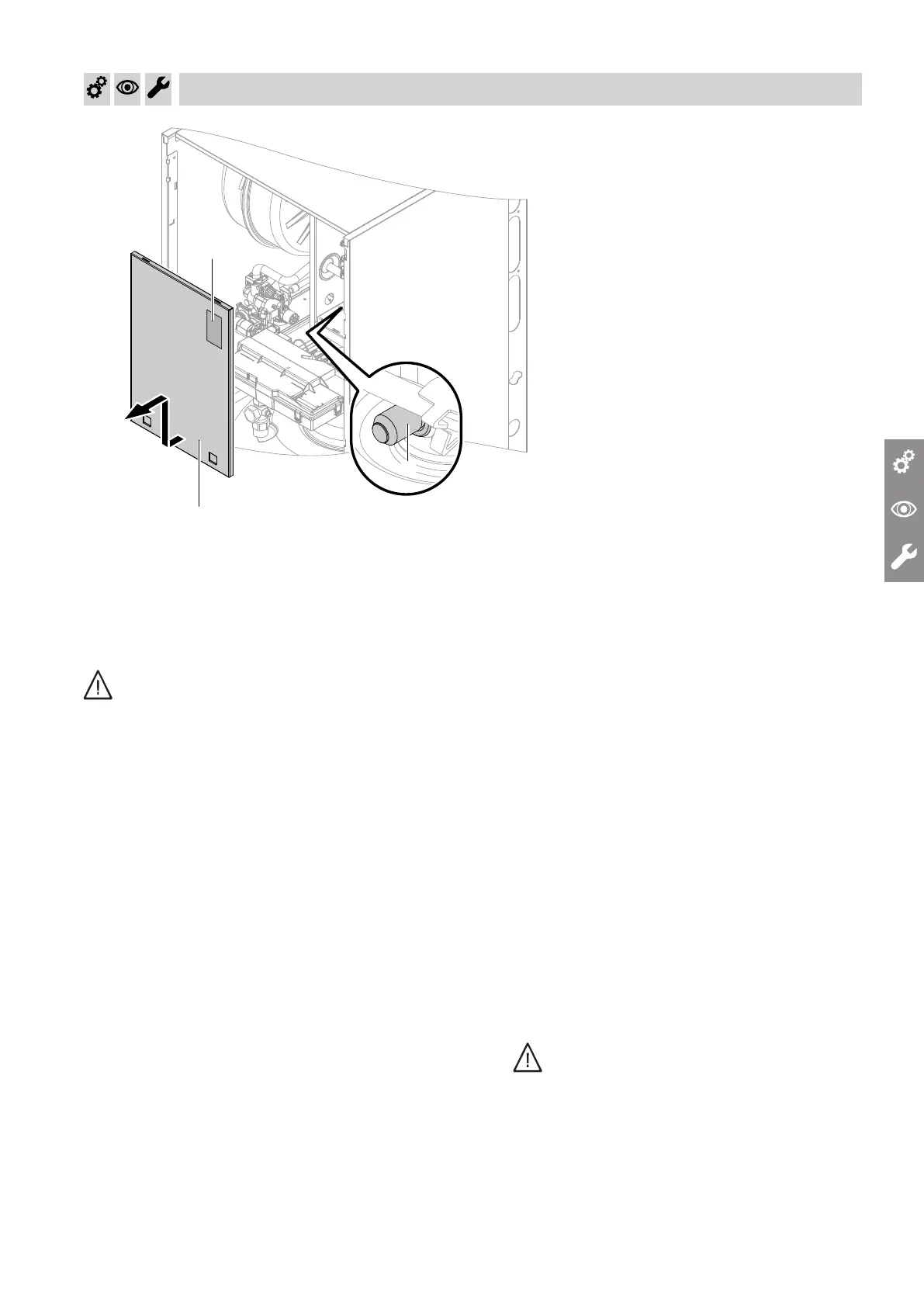

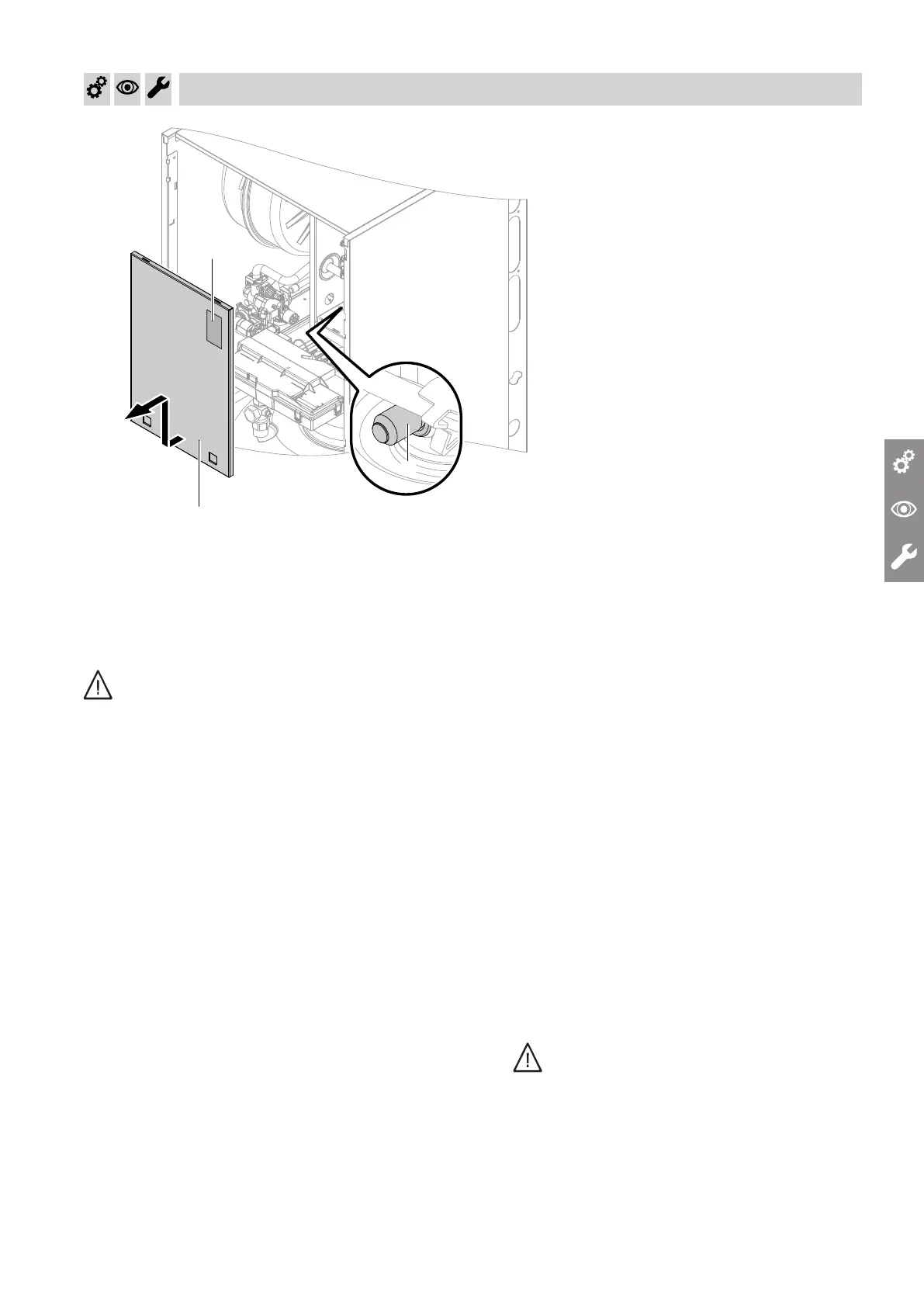

Fig. 29

A

Cover panel

B

Test connector

C

Type plate

Danger

CO formation as a result of incorrect burner

adjustment can have serious health implications.

Carry out a CO test before and after work on

gas appliances.

Operation with LPG

Purge the LPG tank twice on commissioning/replace-

ment. Vent the tank and gas connection line thoroughly

after purging.

01. Close the gas shut-off valve.

02.

Undo clips and remove cover panel

A

.

03.

Undo screw in test connector

B

on the gas train,

but do not remove it. Connect the pressure gauge.

04. Open the gas shut-off valve.

05. Test the static pressure and record it in the report.

Set value: Max. 57.5 mbar (5.75 kPa).

06. Start the boiler.

Note

During commissioning, the appliance can enter a

fault state if there are airlocks in the gas line.

Reset the appliance after approx. 5 s (see operat-

ing instructions).

07. Check the supply (flow) pressure. For set values,

see the following table.

Note

Use a suitable measuring device with a resolution

of at least 0.1 mbar (0.01 kPa) to check the supply

pressure.

08. Record the actual value in the report.

Implement measures as indicated in the table

below.

09. Shut down the boiler. Close the gas shut-off valve.

10. Remove the pressure gauge. Tighten the screw in

test connector

B

.

11. Open the gas shut-off valve and start the appli-

ance.

Danger

Gas escaping from the test connector leads

to a risk of explosion.

Check gas tightness at test connector

B

.

12.

Fit cover panel

A

.

Commissioning, inspection, maintenance

Checking the static pressure and supply pressure

6151778

Loading...

Loading...