56

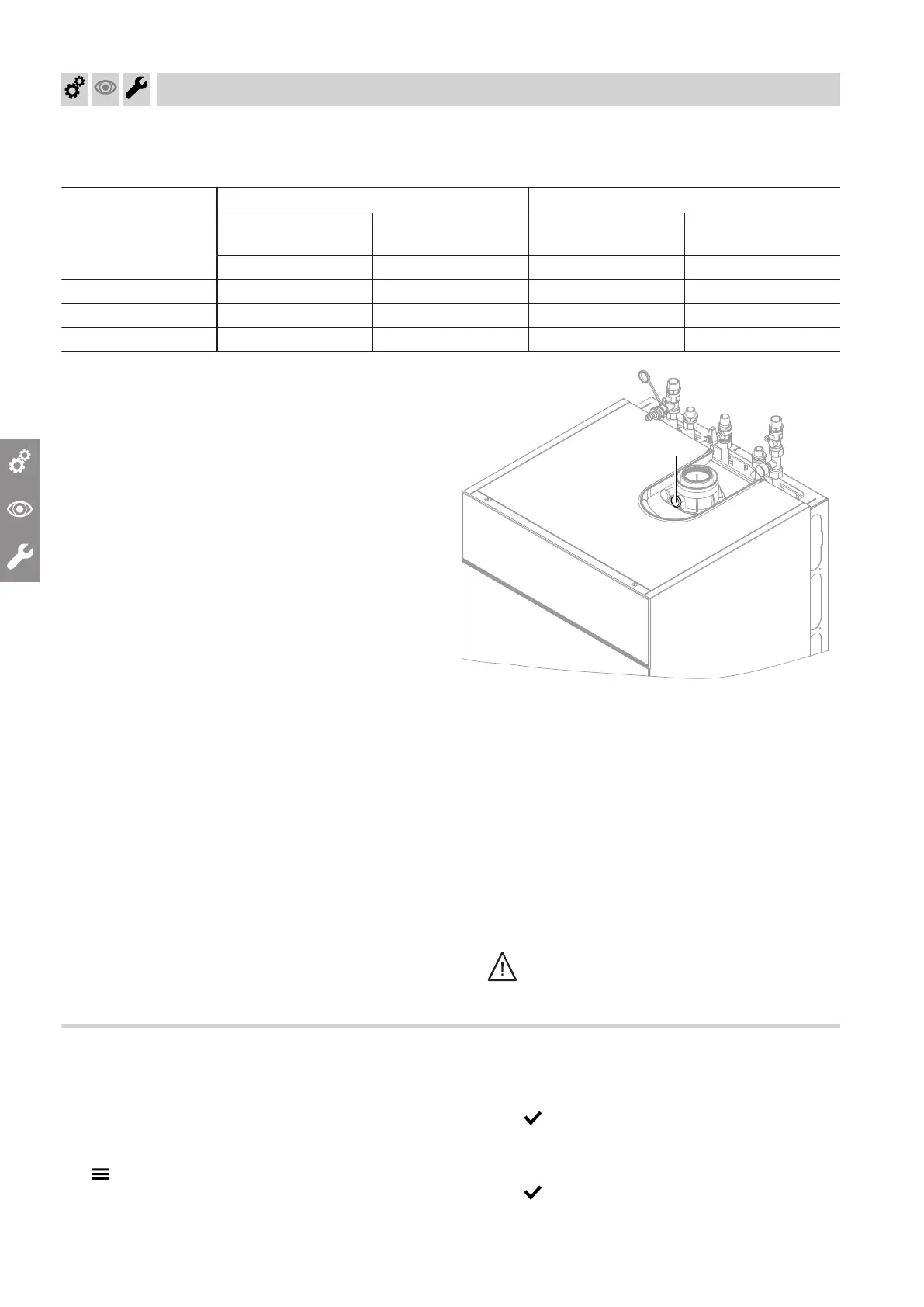

Permissible CO

2

or O

2

content

Operation with natural gas

Rated heating out-

put (kW)

CO

2

content (%) O

2

content (%)

Upper heating out-

put

Lower heating out-

put

Upper heating out-

put

Lower heating out-

put

11

7.3 - 10.5 7.5 - 10.5 2.1 - 7.9 2.1 - 7.6

19 7.5 - 10.5 7.5 - 10.5 2.1 - 7.6 2.1 - 7.6

25 7.5 - 10.5 7.5 - 10.5 2.1 - 7.6 2.1 - 7.6

32 7.3 - 10.0 7.5 - 10.5 3.1 - 7.9 2.1 - 7.6

Operation with LPG

■

CO

2

content: 8.4 - 11.8 %

■

O

2

content: 3.1 - 8.1 %

If the actual CO

2

or O

2

values lie outside their respec-

tive ranges, proceed as follows:

■

Check the balanced flue system for leaks; see

page 43.

■

Check ionisation electrode and connecting cable.

Note

During commissioning, the combustion controller car-

ries out an automatic calibration. Only measure the

emissions approx. 50 s after the burner has started.

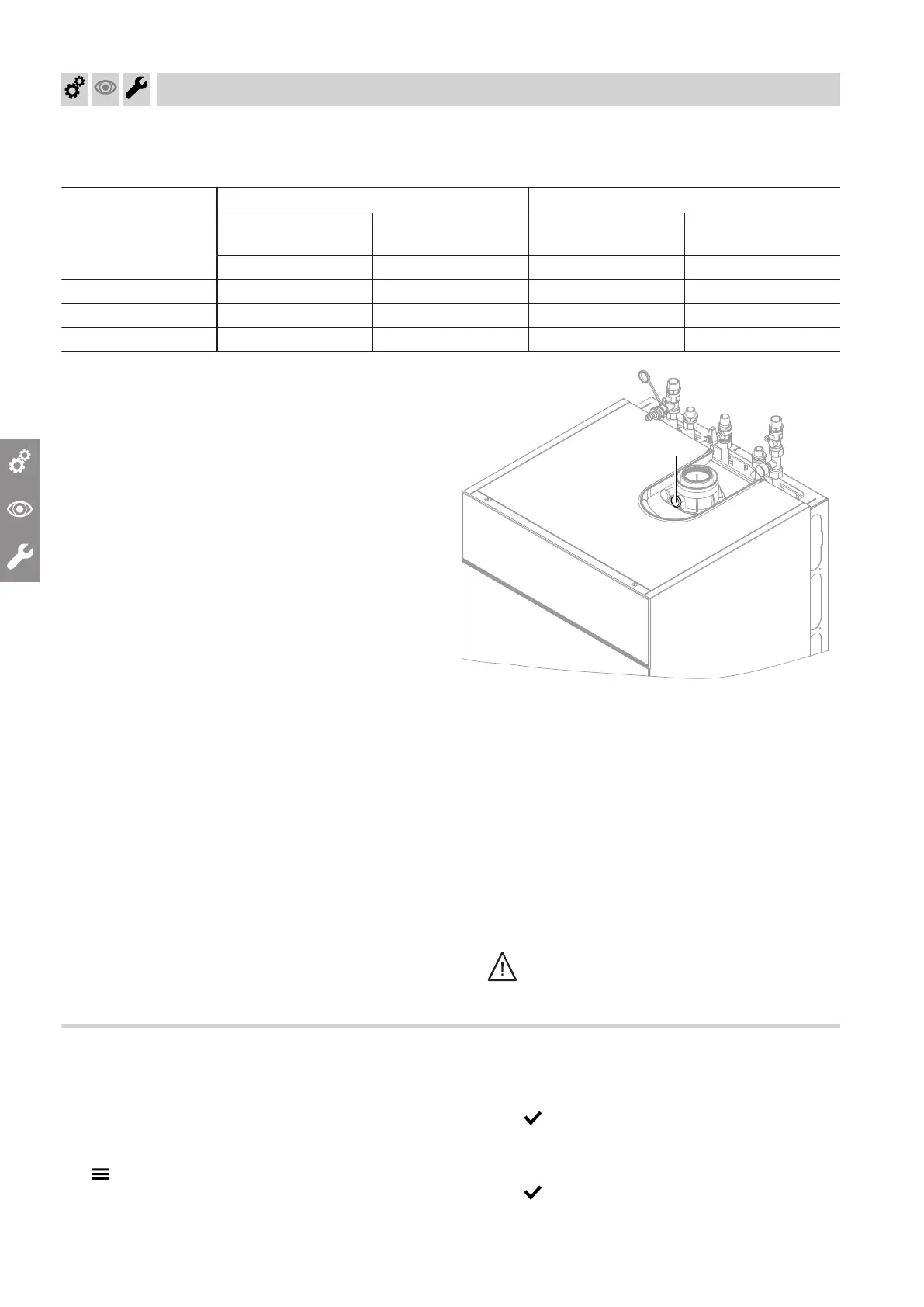

Fig. 47

1.

Connect a flue gas analyser at flue gas port

A

on

the boiler flue connection.

2. Open the gas shut-off valve. Start the boiler. Cre-

ate a heat demand.

3. Adjust the lower heating output. See the following

chapter.

4. Check the CO

2

content. If the actual value deviates

from the permissible ranges, implement steps lis-

ted above.

5. Enter the actual value into the report.

6. Adjust the upper heating output. See the following

chapter.

7. Check the CO

2

content. If the actual value deviates

from the permissible ranges by more than 1 %,

implement steps listed above.

8. Enter the actual value into the report.

9.

Re-seal test port

A

.

Danger

Escaping flue gas can damage your health.

Check test port

A

for leaks.

Selecting the upper/lower heating output

Note

Ensure adequate heat transfer.

Tap the following buttons:

01.

02. "Service"

03. Enter password "viservice".

04. Use to confirm.

05. "Actuator test"

06. Use to confirm.

Commissioning, inspection, maintenance

Checking the combustion quality (cont.)

6151778

Loading...

Loading...