84

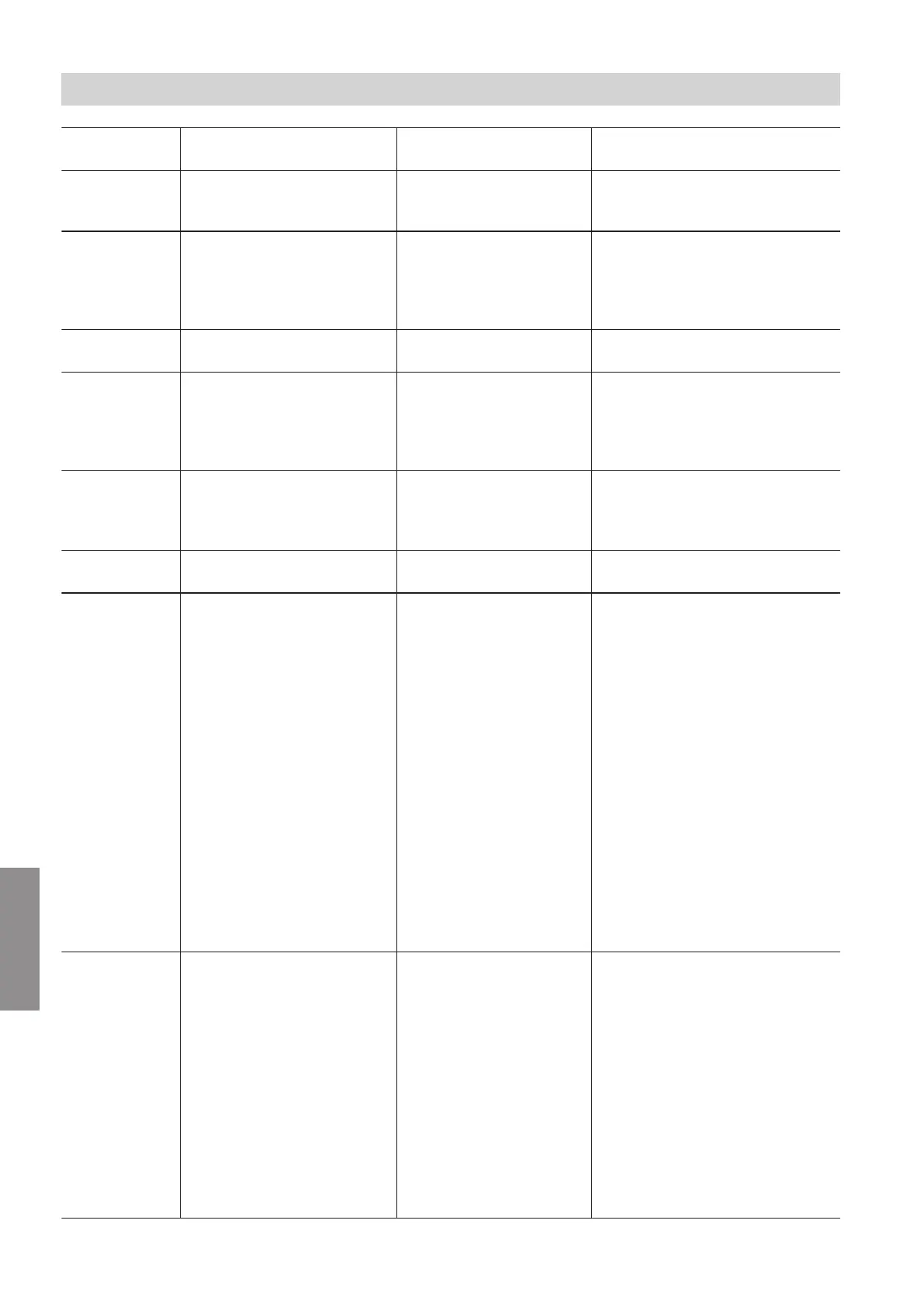

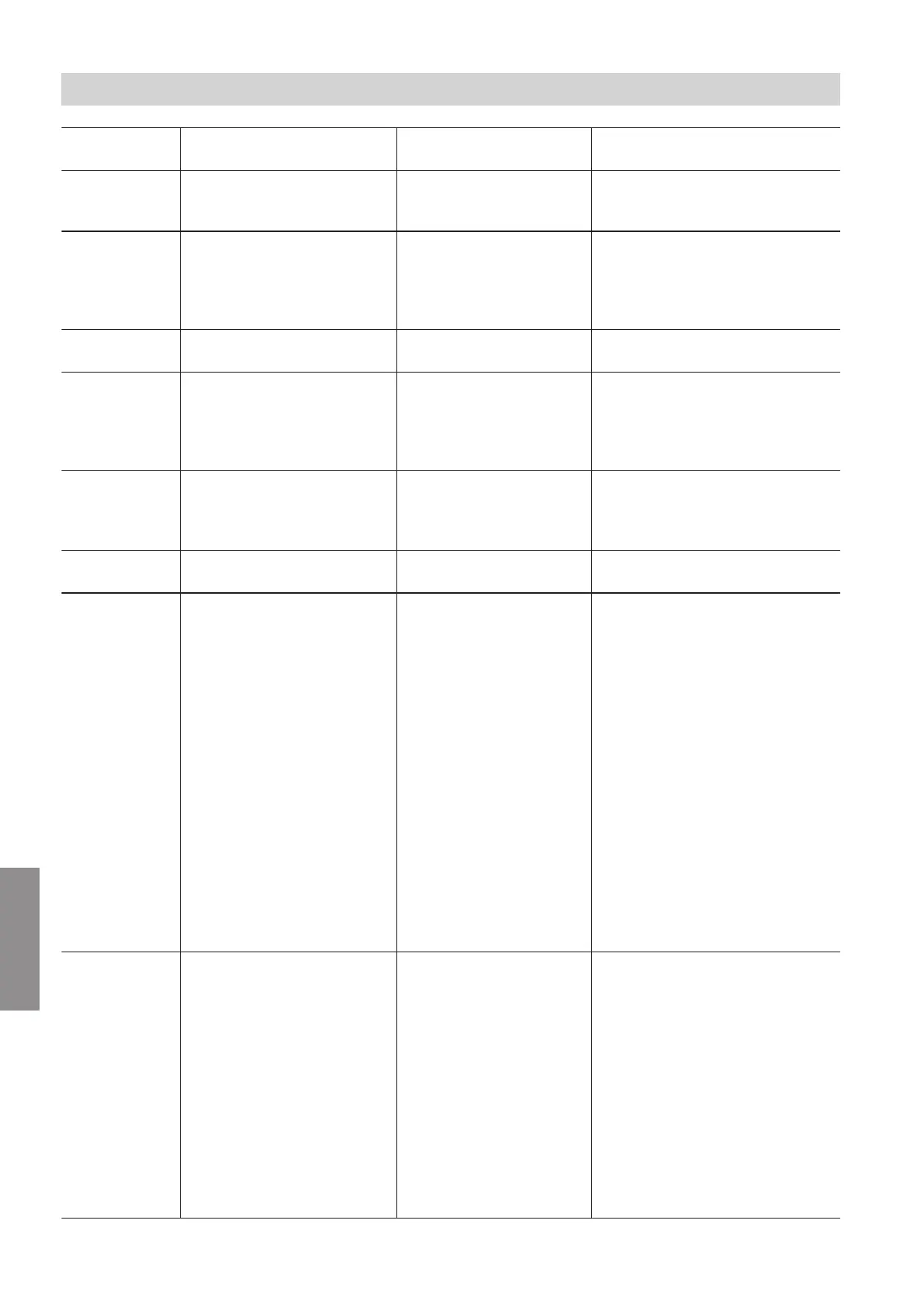

Displayed fault

code

System characteristics Cause Measures

F.163 Burner in a fault state Memory access checksum

error BCU

Reset the appliance.

If fault recurs, replace BCU burner

control unit: See page 100.

F.182 No DHW heating Short circuit, outlet tem-

perature sensor (if instal-

led)

Check outlet temperature sensor

(plug X1, cores 13 and 14). Meas-

ure sensor input on electronics

module. Set value: 3.3 V

–

with

sensor disconnected

F.183 No DHW heating Lead break, outlet temper-

ature sensor (if installed)

Check outlet temperature sensor

(plug X1, cores 13 and 14).

F.184 Burner in a fault state Short circuit, flow temper-

ature sensor/high limit

safety cut-out

Check the flow temperature sen-

sor/high limit safety cut-out.

Check sensor lead. Replace faulty

component if required.

Reset the appliance.

F.185 Burner in a fault state Lead break, flow tempera-

ture sensor/high limit safe-

ty cut-out

Check the flow temperature sen-

sor/high limit safety cut-out. Re-

place faulty component if required.

Reset the appliance.

F.299 Time/date incorrect Real time clock setting in-

correct

Set the time and date.

F.342 No central heating, no DHW

heating

Communication error,

burner control unit BCU

■

Check connecting cable to the

burner control unit plug X4 on

BCU.

■

Check all plug-in connections

and cables of the internal CAN.

■

Remove all plugs except X4, X2,

X16 and X18 from the BCU burn-

er control unit. Check whether

fault persists.

Note

Several other fault messages will

be added due to the removed

plugs. Ignore these. If fault mes-

sage F.342 is no longer shown, re-

insert the plugs one by one and es-

tablish which component is faulty.

Reset the appliance.

F.345 Burner locked out, automatic

enabling after appliance cool-

down. Independent restart.

Temperature limiter has

responded.

See heat generator speci-

fication.

■

Ensure adequate heat transfer.

■

Check heating system fill level.

■

Check pre-charge pressure in di-

aphragm expansion vessel. Ad-

just to required system pressure.

■

Check whether flow rate is suffi-

cient (flow sensor and pump).

■

Check 3-way diverter valve func-

tion in actuator test. Vent the sys-

tem.

If the fault occurs during DHW

heating: Check DHW cylinder or

plate heat exchanger for contami-

nation and scaling.

Troubleshooting

Fault messages (cont.)

6151778

Service

Loading...

Loading...