SECTION TSM 344 ISSUE E PAGE 18 OF 24

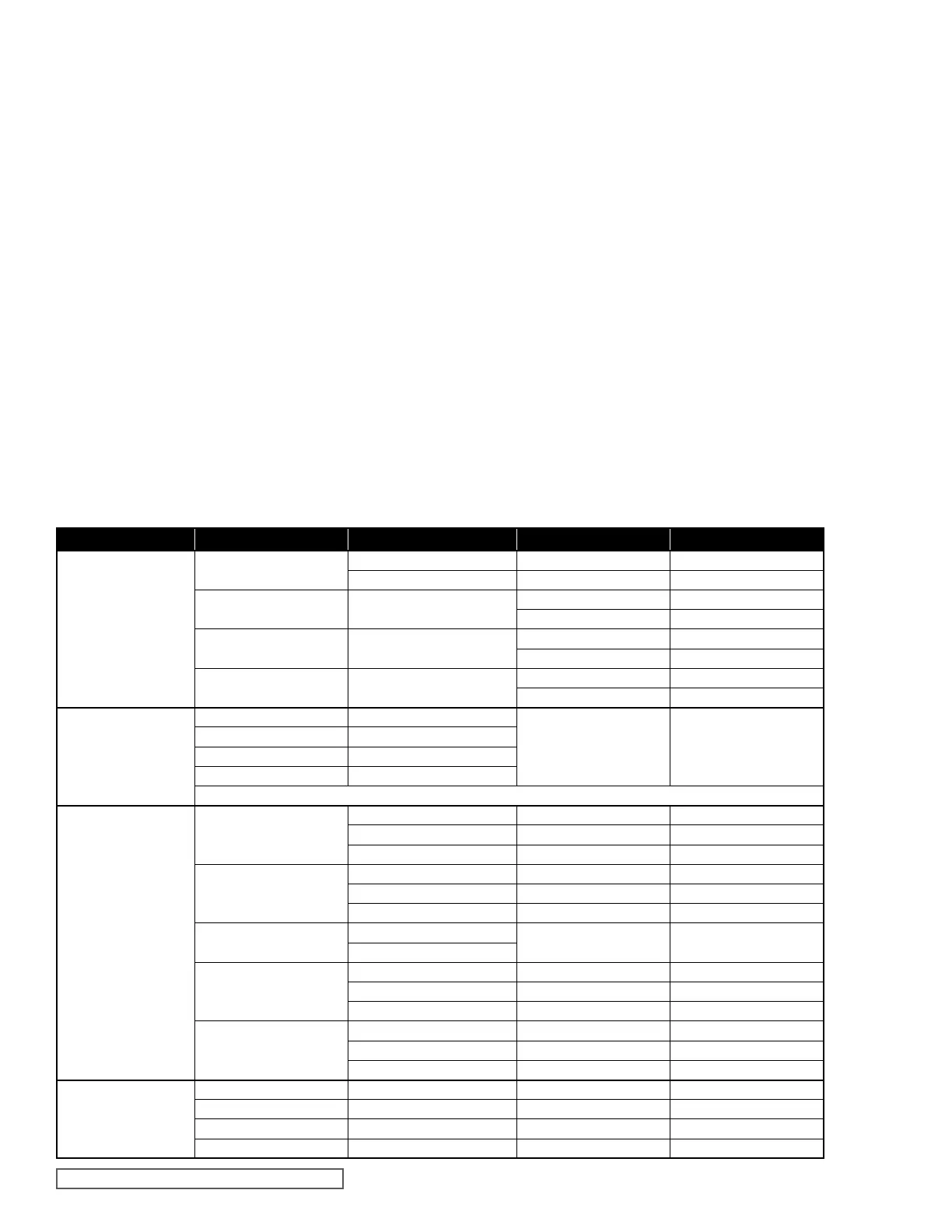

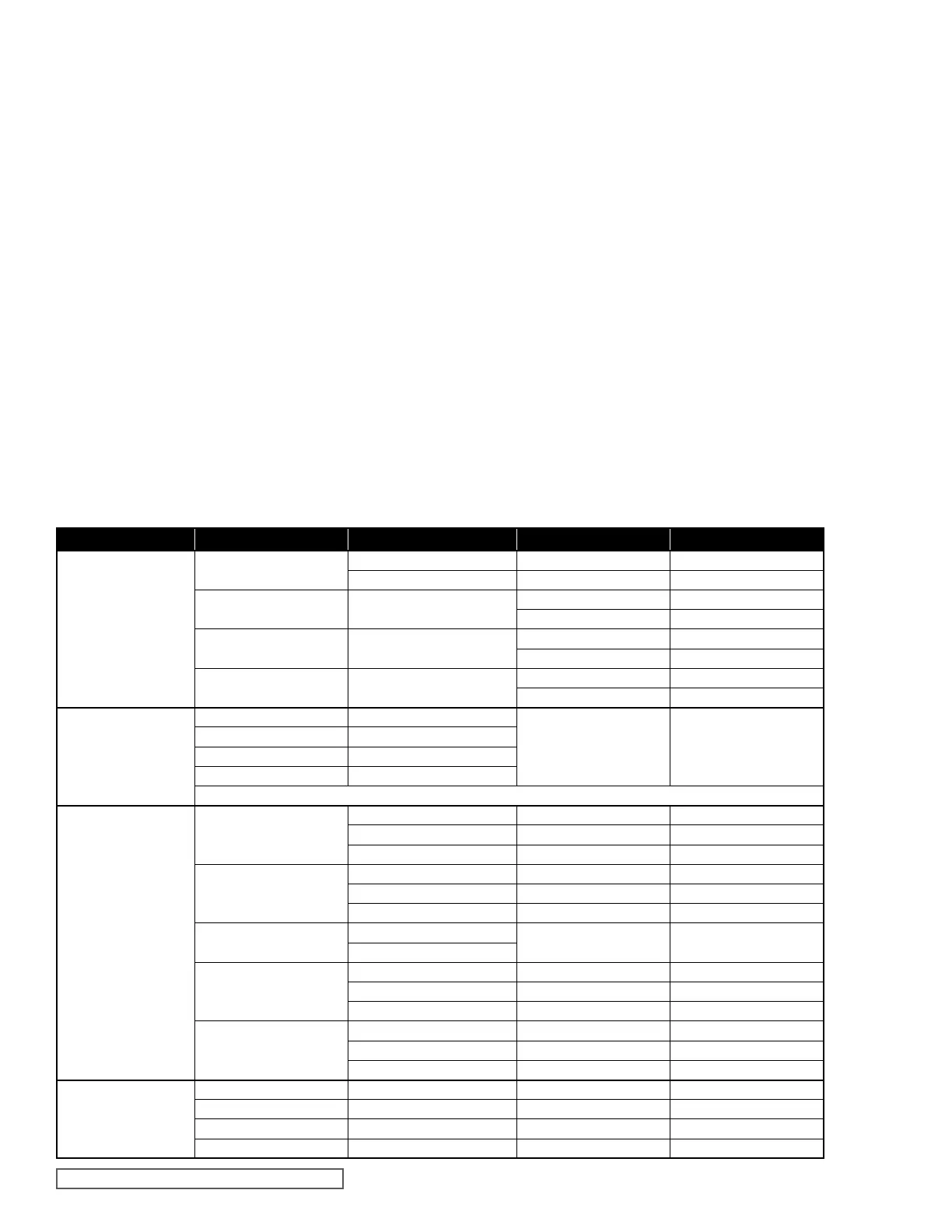

Bearings

E02

ID 0.293” 0.0025 bore wear 0.005 bore wear

Length 0.499” end wear – flip over both ends worn

E05 and E12 ID 0.439”

0.003 bore wear 0.006 bore wear

end wear – flip over both ends worn

E25 ID 0.627”

0.004 bore wear 0.008 bore wear

end wear – flip over both ends worn

E75 and E125 ID 1.002”

0.005 bore wear 0.010 bore wear

end wear – flip over both ends worn

Shafts

E02 OD 0.2916”

0.001 smooth wear

0.001 deep or rough

scoring

E05 and E12 OD 0.437”

E25 OD 0.625”

E75 and E125 OD 1.000”

no cracks or chips in shaft surface are allowed

Gears

E02

Length 0.4055” 0.0005 wear – length 0.001 wear – length

OD 0.600” 0.003 wear – OD 0.006 wear – OD

0.010 Backlash 0.020 Backlash

E05

Length 0.624” 0.001 wear – length 0.002 wear – length

OD 1.063” 0.004 wear – OD 0.008 wear – OD

0.015 Backlash 0.030 Backlash

E12

Length 1.249”

Same as E05 above Same as E05 above

OD 1.063”

E25

Length 1.499” 0.002 wear – length 0.004 wear – length

OD 1.417” 0.005 wear – OD 0.010 wear – OD

0.020 Backlash 0.040 Backlash

E75 and E125

Length 1.998” 0.003 wear – length 0.006 wear – length

OD 2.125” 0.006 wear – OD 0.012 wear – OD

0.025 Backlash 0.050 Backlash

Housing Liner

E02 n/a 0.002 wear or step 0.004 wear or step

E05 and E12 n/a 0.003 wear or step 0.006 wear or step

E25 n/a 0.004 wear or step 0.008 wear or step

E75 and E125 n/a 0.005 wear or step 0.010 wear or step

Inspect internal pump components as follows:

Inspect bearing bores (2) and end surfaces for wear and

scoring. If wear or scoring is present on the end surface

of the bearing, the bearing can be flipped to expose the

undamaged face to the gear side. Bearing should be

replaced when both ends show wear and/or scoring, or when

the bores have reached the replacement limit (see chart).

Both the idler and the drive shaft should be inspected

carefully for scoring, wear, and any signs of cracking or chips

in the surface of the ceramic material. No cracks or chips

are allowed. Shafts should be replaced if they show signs of

cracks or chips anywhere on the surface, if they are deeply

scored, or if they have reached their replacement limit (see

chart).

Gears can be measured for dimensional change to their

length and outside diameter. Gear teeth should also be

visually inspected for wear and damage. Gear teeth can

be damaged due to solids moving through the pump, which

will affect only some teeth, or excessive pressure, which

will distort the outside tips of all teeth. Gears that have

reached their replacement limits (see chart) or show signs of

physical damage or distortion should be replaced. Backlash

can be checked by temporarily inserting the two gear/shaft

assemblies into known good bearings and observing gear

tooth mesh and backlash.

The housing liner should be visually inspected for scoring,

wear, and steps on the ID of the two gear bores. See chart

for specific limits.

The viscosity of the pumped product will affect the service

limits of your CMD pump. Fluids with higher viscosities will

usually be more tolerant of wear and allow longer maintenance

intervals. Fluids with low viscosities will usually require more

frequent maintenance, as they are less tolerant of clearances

between the pump’s internal surfaces. Each application is

different, and only regular inspection and good records will

determine what the correct maintenance interval is for your

application.

Loading...

Loading...