12

Installation (continued)

9

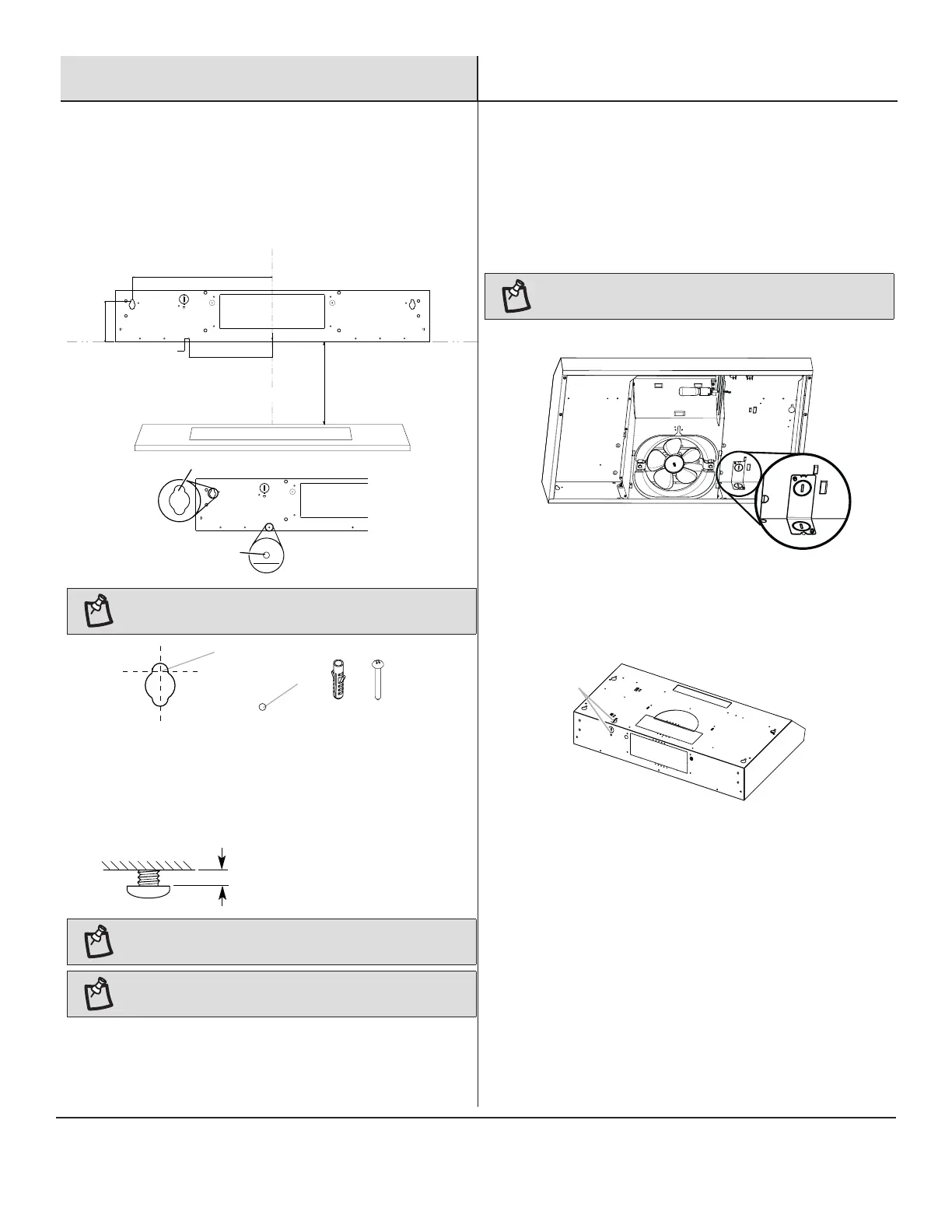

Preparing the location (wall mounting)

□ Determine de distance from the cooking surface to mounting

holes.

□ Taking as base the horizontal line and the center line of the wall,

mark the location of the four keyhole mounting slots, as shown.

7-3/16 in. (20.12 cm)

13-5/16 in. (33.78 cm)

5/16 in.

(.79 cm)

3-7/8 in.

(9.85 cm)

Distance from

cooking surface

Centerline

Pilot Holes

Safety Holes

NOTE: Make the drill holes on the thin area of the slot.

CC

BB

1. Drill Pilot Hole

2. Drill Safety Hole

1

2

□ Use a 3/10 in. (8 mm) drill bit and drill two pilot holes (1) and

two safety holes (2).

□ Insert four wall anchors (BB) in those holes.

□ Install the two of the 5 x 45 mm upper mounting screws (CC)

in pilot holes. Leave about 1/4 in. (6.4 mm) space between

screw heads and wall to slide range hood into place.

(6.4 mm)

in.

1/4

NOTE: Leave the safety holes without screws.

NOTE: If the wall is wood, do not use anchors (use 3mm drill).

10

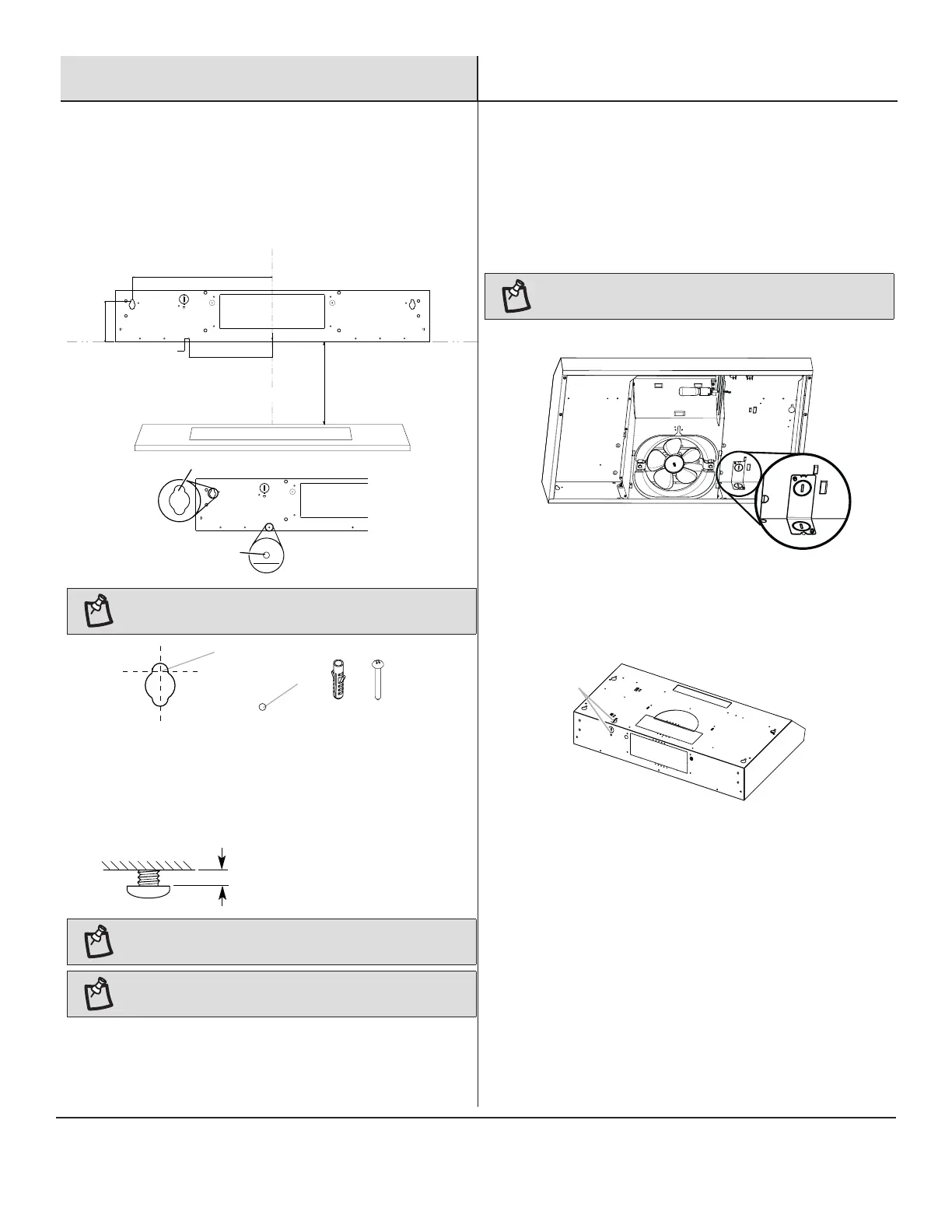

Installing power supply cable

□ For direct wire installations, run the home power supply cable

according to the National Electric Code or CSA standards and

local codes and ordinances. There must be enough wiring

from the fused disconnect (or circuit breaker) box to make the

connection in the hood electrical terminal box.

NOTE: Do not reconnect power until the installation is

complete.

Location

of cables

□ Remove the power supply knockout (1) from the top or rear

of the vent hood (depending on the incoming location of your

home power supply cable) and install a UL listed or CSA

approved 1/2 in. strain relief (not included).

1

□ Lift the hood into nal position (see Installation section steps

11 or 12 depending the kind of installation you need). Feed

enough electrical wire through the 1/2 in. UL listed or CSA

approved strain relief to make connections in the terminal box.

Tighten the strain relief screws.

□ Connect ventwork to hood. Seal joints with vent clamps or duct

tape to make secure and airtight.

□ Check that back draft dampers work properly.

Loading...

Loading...