10TA Service Manual

TROUBLESHOOTING

4/23/14

8-9

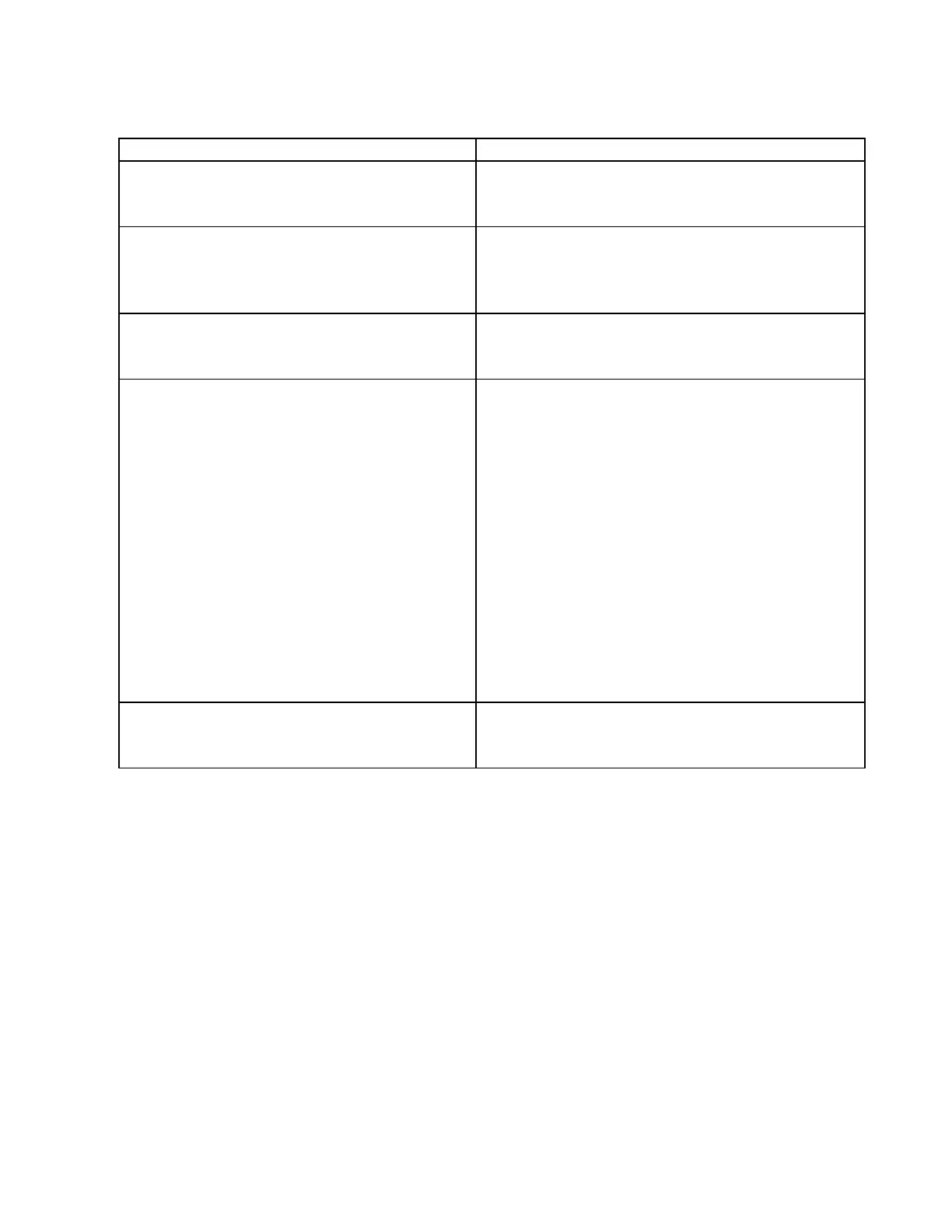

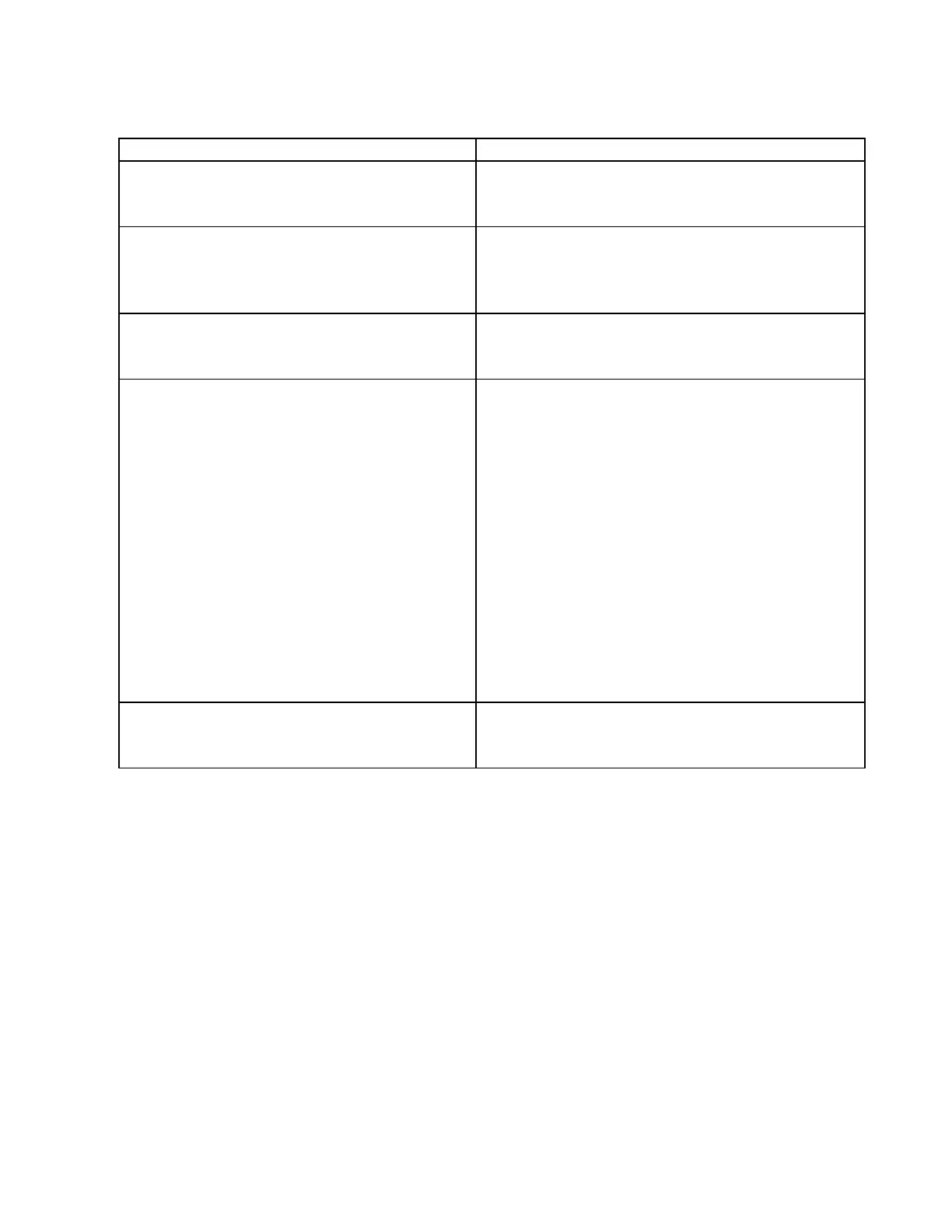

SYMPTOM:

High head pressure. (Water cooled machine)

POSSIBLE CAUSE POSSIBLE REMEDY

Misadjusted or defective water regulating

valve

Adjust or replace the valve. Never adjust the

valve stem as far open as it will turn, because it

will not close when the head pressure drops.

Insufficient water supply. Check size of water line and pump output at the

condenser. Refer to the specification sheet for

water requirements. Check cooling tower sump

level and make-up water supply.

Cooling tower needing maintenance. Check cooling tower fan belt and tighten or

replace as needed. Check spray nozzles and

sump screen and clean as needed.

Non-condensables (usually air) in system. Check refrigerant tables for

pressure/temperature relation. If non-

condensables are present, Perform a total

pumpdown, let stand for at least 6 hours,

allowing non-condensables to gather in the

upper part of the receiver. Evacuate the freezer

and attach a recovery unit to the top receiver

purge valve (59). Open the valve and recover

the vapor for about five minutes. When the

freezer is evacuated, open the thaw gas solenoid

valve manually for about 15 seconds letting the

top vapor in the receiver blow into the freezer.

Close the solenoid valve and evacuate the

freezer again. Evacuate to 500 microns and

restart the machine.

Fouled (dirty) condenser. Follow the diagnostic procedure outlined in,

Section 7, and clean the condenser per

instructions under Condenser Cleaning,

Loading...

Loading...