Service and maintenance

162 Central lubrication

Central lubrication

The machine can be equipped with a central lubrication system

that automatically greases a number of points according to a pre-

selected lubrication cycle. The lubrication system shall be

inspected at regular intervals and should be coordinated with other

maintenance and checking.

Check the following at regular intervals:

– that there is enough lubricant in the reservoir. Fill as needed,

see below.

NOTE! Too low level of lubricant results in high risk of air

getting in to the system (most common cause of

malfunction).

– that the system works. Perform the system test on page 165.

– that the lubricant reservoir is not damaged.

– that the connections seal tight.

– that the quick-couplings' dust caps are installed and not

damaged.

– that the grease lines are not damaged and well fastened.

– that the greasing point is greased (that lubricant is forced out at

the bearing).

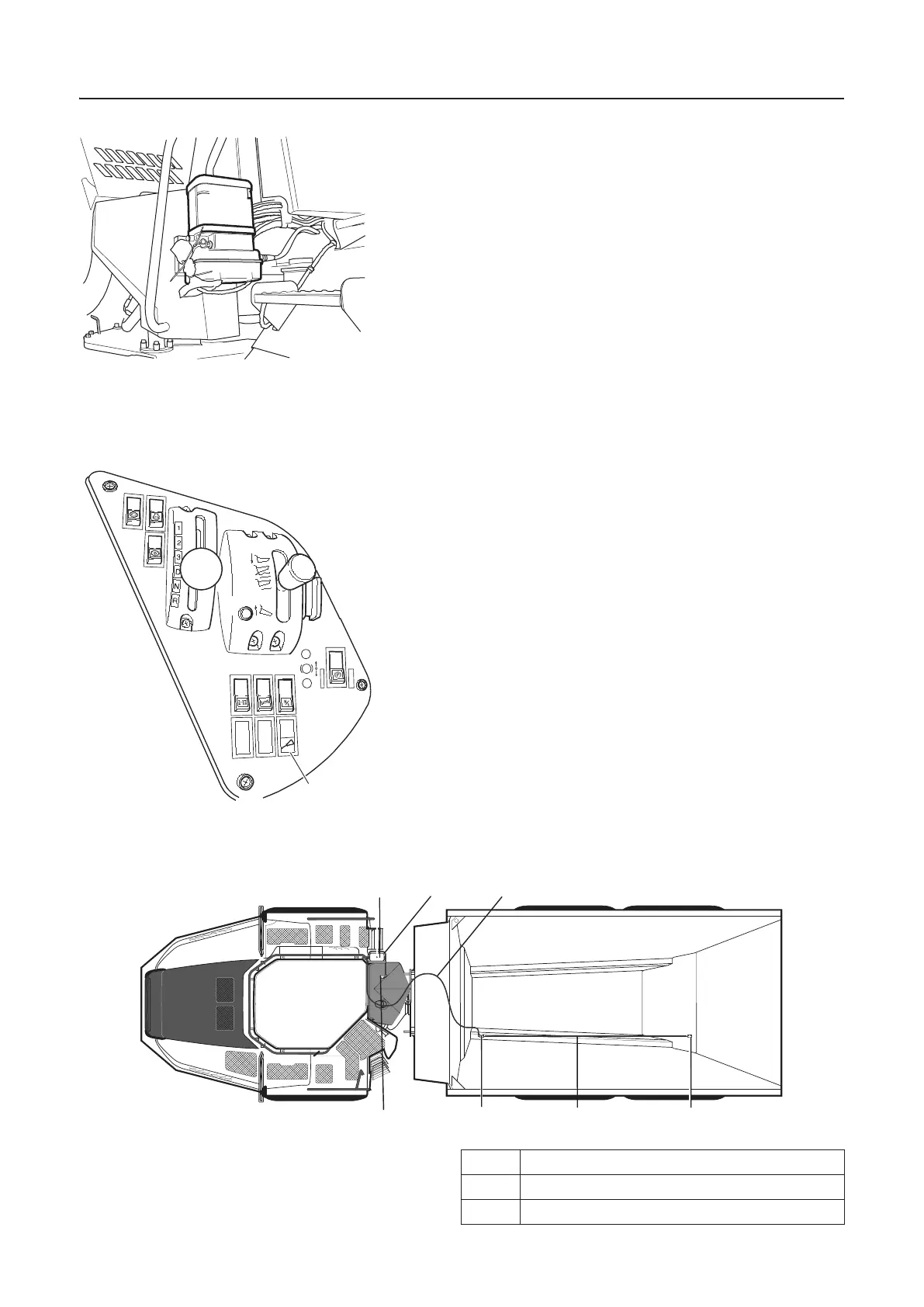

A

Reservoir

B

Dosage block

C

Main line

Reservoir for lubricant

P

l

A

1048497

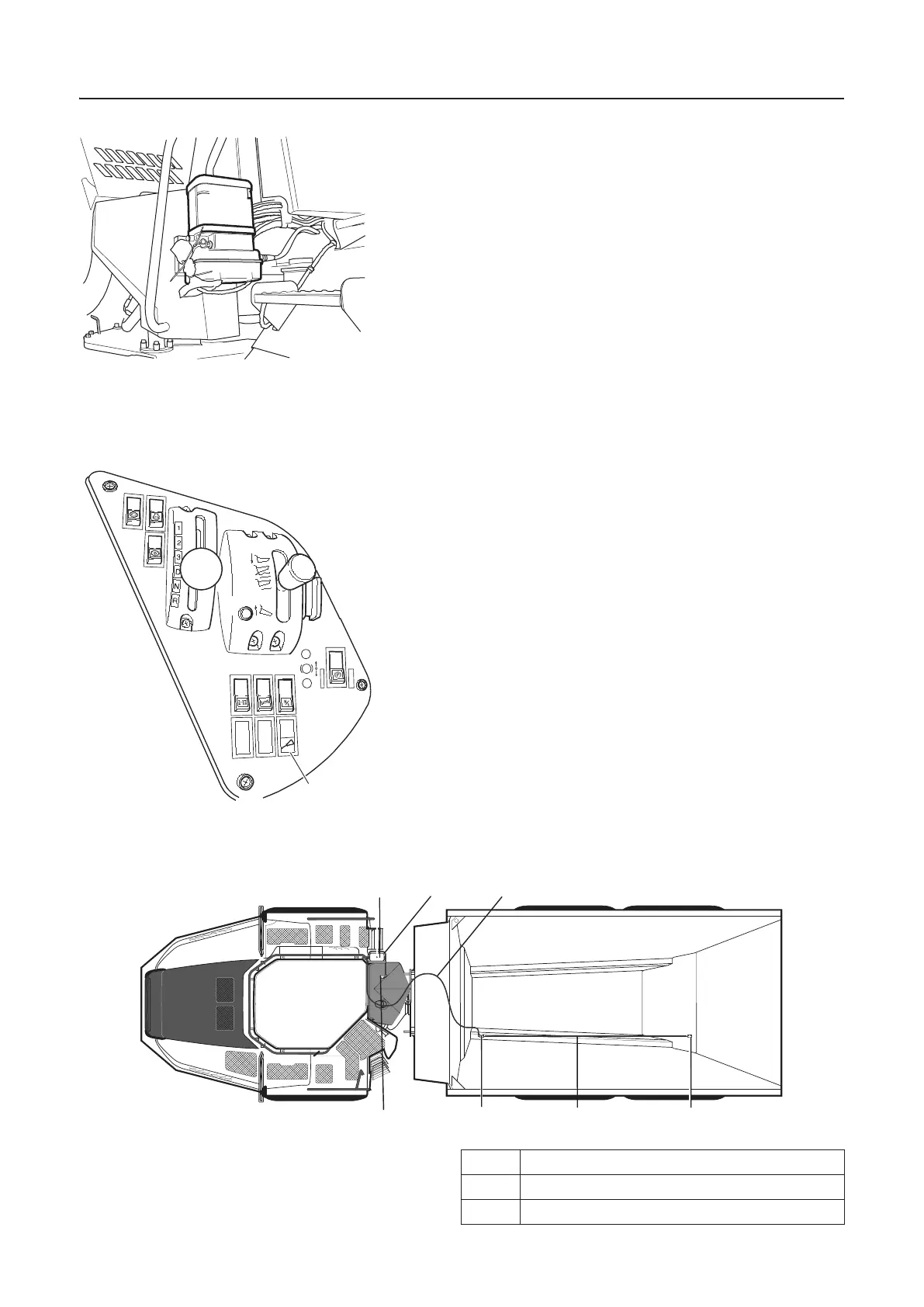

A Control light for lubrication in progress

A

CC

B

B

B

C

1044703

Loading...

Loading...