Service and maintenance

166 Central lubrication

Continuous lubrication test cycle

The pump runs an unlimited number of lubrication cycles, that

is, continuously pumps lubricant, alternating between both main

lines. Used when bleeding air from the system.

1 Turn the ignition key to position 1 (operating position).

2 Press in the test button for longer than 6 seconds.

3 The lubrication cycle starts.

4 End the test cycle by turning the start key to position 0.

The test cycle does not end automatically.

Bleeding air from the system

The pump may not be activated for longer than five minutes.

1 Make sure that the lubricant reservoir is filled to the max.

marking.

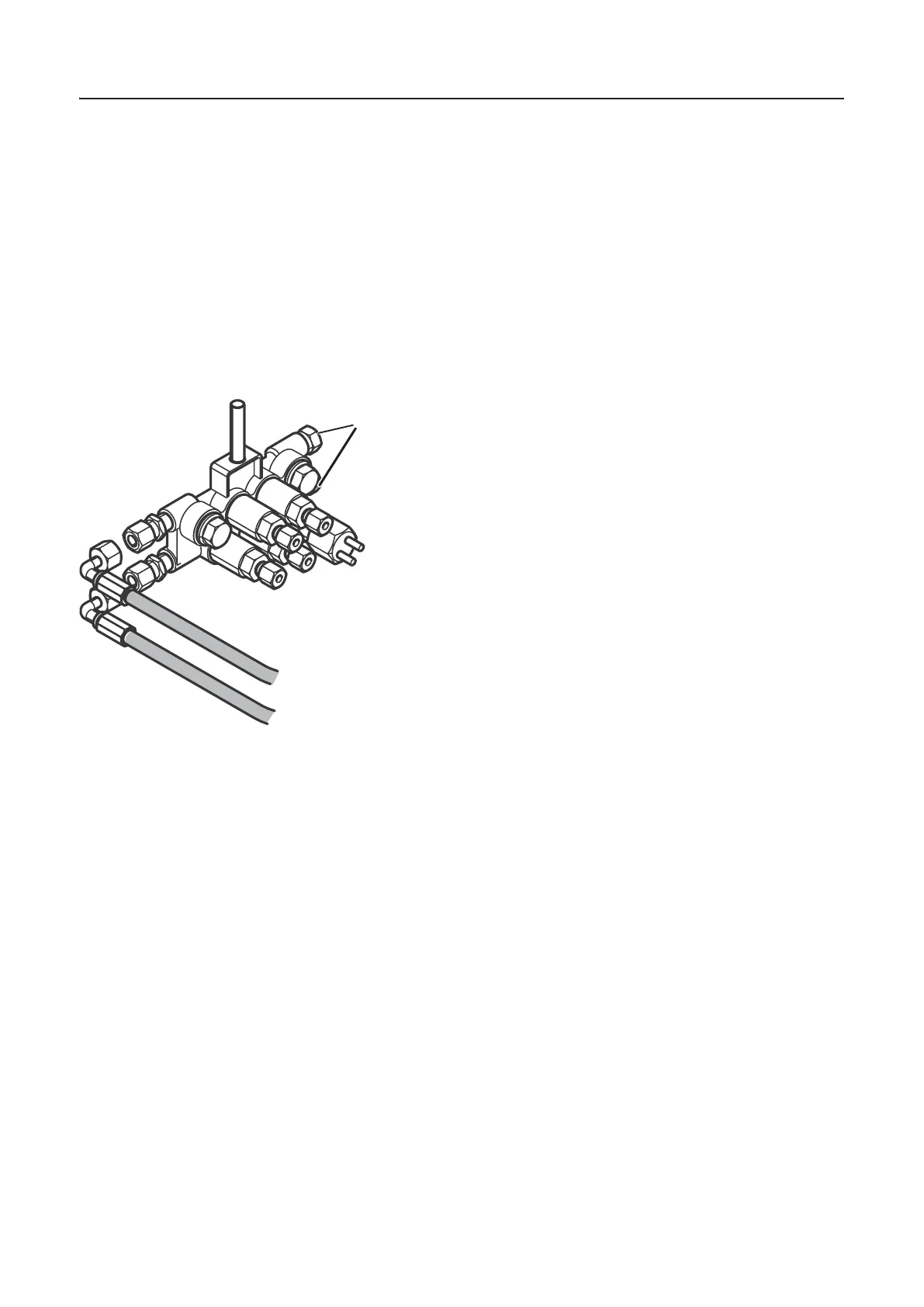

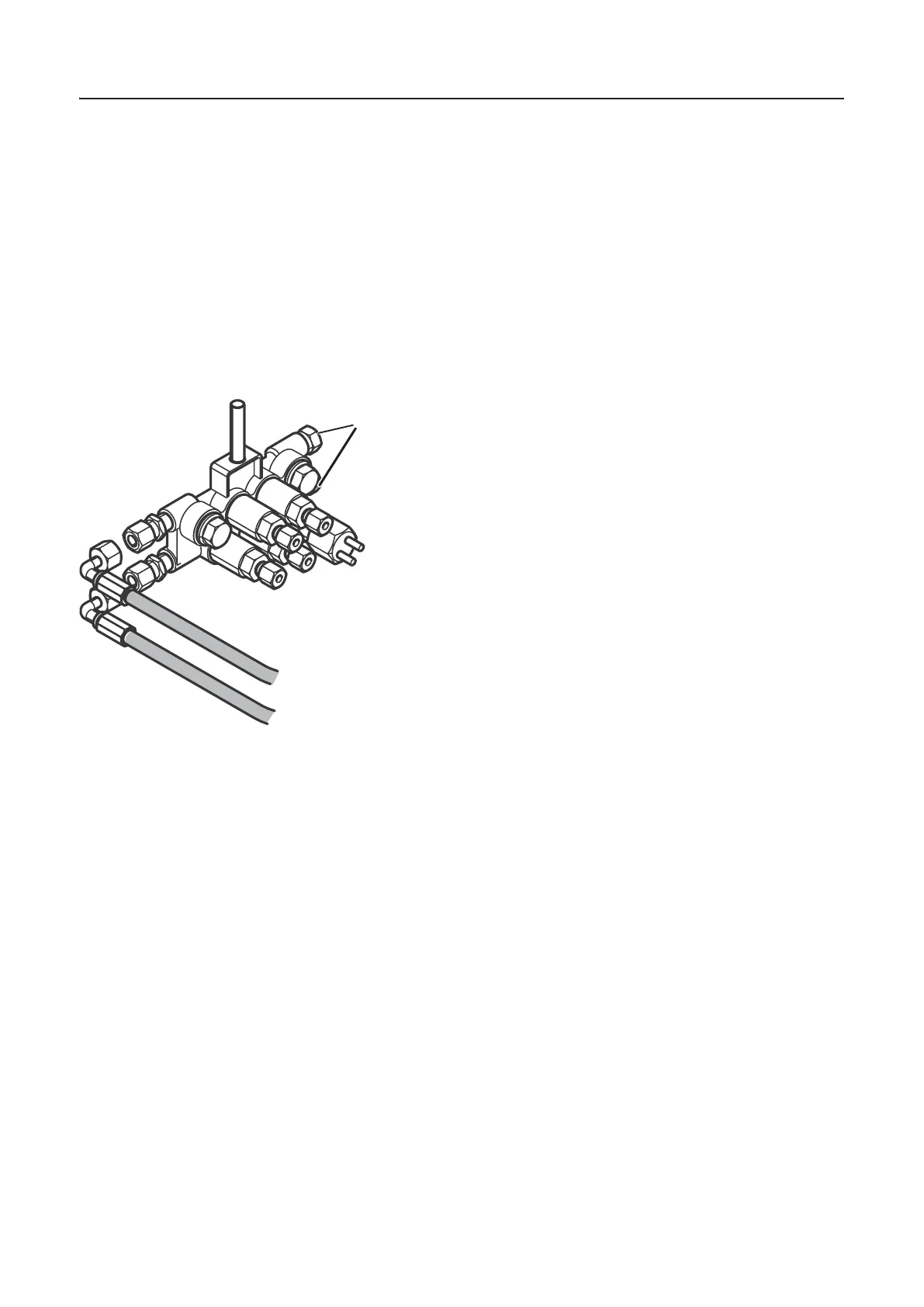

2 Remove the plugs for the main lines (A), one at a time, in the

dosage block that is farthest from the pump unit.

3 Turn the ignition key to position 1 (operating position).

4 Press the test button for more than 6 seconds, which

corresponds to a continuous test cycle.

5 When lubricant free from air comes out of the main line, air

bleeding is done for that main line.

6 Turn the start key to 0-position and install the plug.

7 Follow points 2–6 to bleed air from the other main line.

8 Test the system with the method “Single lubrication test cycle”,

see previous page.

Cleaning with high-pressure washer

Normally, water cannot get in to the system. However, the risk is

higher when using a high-pressure washer.The pump unit should

be protected since water that gets in to the system cannot get out

by itself, instead it may cause malfunctions. After high-pressure

washing, run a“Single lubrication test cycle” to get extra

lubrication.

1043496

Loading...

Loading...