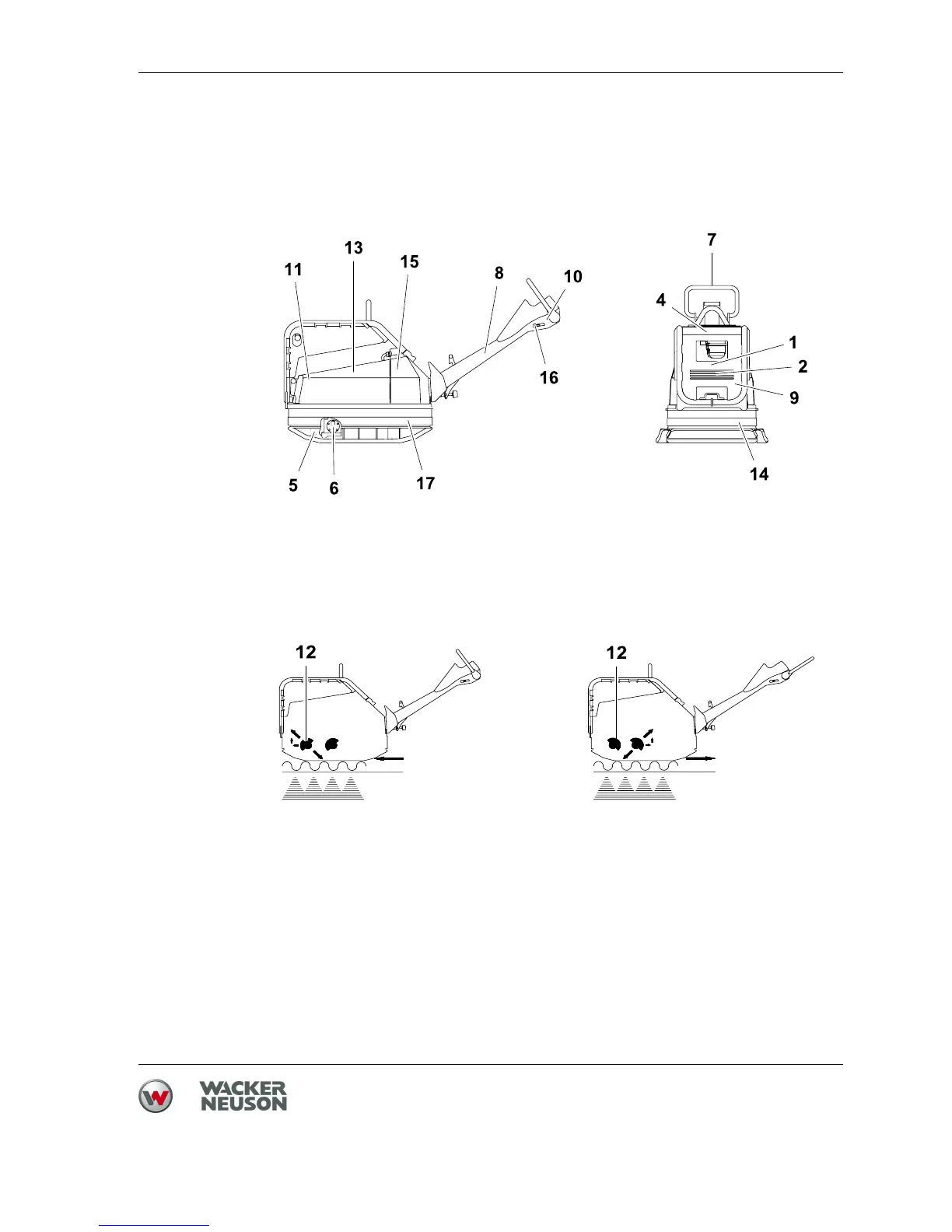

DPU 100-70Les 4 Description

Operator's manual 23

4 Description

4.1 Description of function

The vibration required for compaction is generated via the exciter (6) which is

firmly connected to the base plate (5). The exciter (6) has been designed as a

centrally mounted exciter with single plane (directional) oscillations.

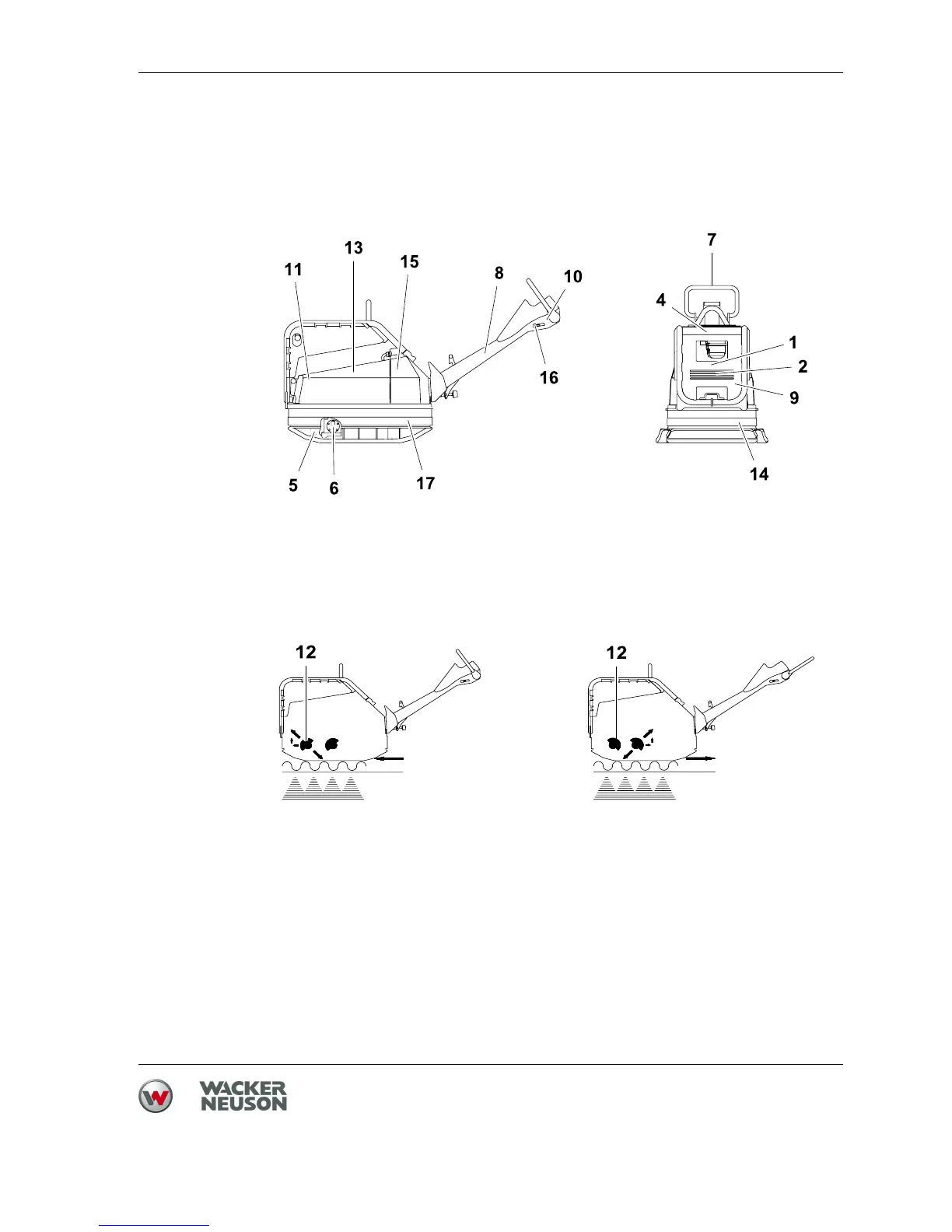

This principle allows for the changing over of the direction of the oscillations by

changing the relative position of the eccentric weights (12). Said principle also

makes it possible to pass from forward travel to reverse travel motion.

This procedure is hydraulically controlled by way of the operating control handle

(7) situated at the upper end of the center pole (8) and an electrically operated

disable switch (9), which receives a switch signal from a roll touch switch (10)

placed at the center pole head. An oil flow governor valve (15) supplies the steer-

ing line with a partial oil flow.

The exciter (6) is driven by an hydraulic motor (14). The oil flow required for the

motor (14) comes from the pump (13), which in turn is driven by the drive engine

(1). The oil cooler (2) cools the hydraulic oil.

The rpm's of the drive engine (1) can be adjusted by way of the remote throttle

Forwards Reverse

Loading...

Loading...