Operating manual Piston Pump EvoMotion 5-125

3 Identification

Order number 2316596 | Edition 03/2021 11

Electrostatic surface spraying

4 Do not spray device parts using electrostatic equipment.

Cleaning

If there are deposits on the surfaces, the device may form electrostatic charges. Flames or

sparks can form during discharge.

4 Remove deposits from the surfaces to maintain conductivity.

4 Use only a damp cloth to clean the device.

Air in the pump fluid

Ignitable gas mixtures can form if air enters the pump fluid.

4 Prevent the pump from taking in air and running dry.

4 If air has been taken in, fix the leak. Then, fill slowly and in a controlled manner until the

air has escaped.

Air in the pumped fluid can be caused by damaged packings.

4 Avoid operating the pump with damaged packing.

4 Ensure that the separating agent tank is filled with sufficient separating agent.

4 Periodically check that the pump is working smoothly, paying special attention to the

presence of air in the pumped fluid.

Filling and emptying

Ignitable gas mixtures can form in the fluid section or product hoses if the pump must be

emptied for maintenance and/or repair purposes.

4 Empty and fill the device slowly and in a controlled manner.

4 Avoid potentially explosive atmosphere in the surroundings.

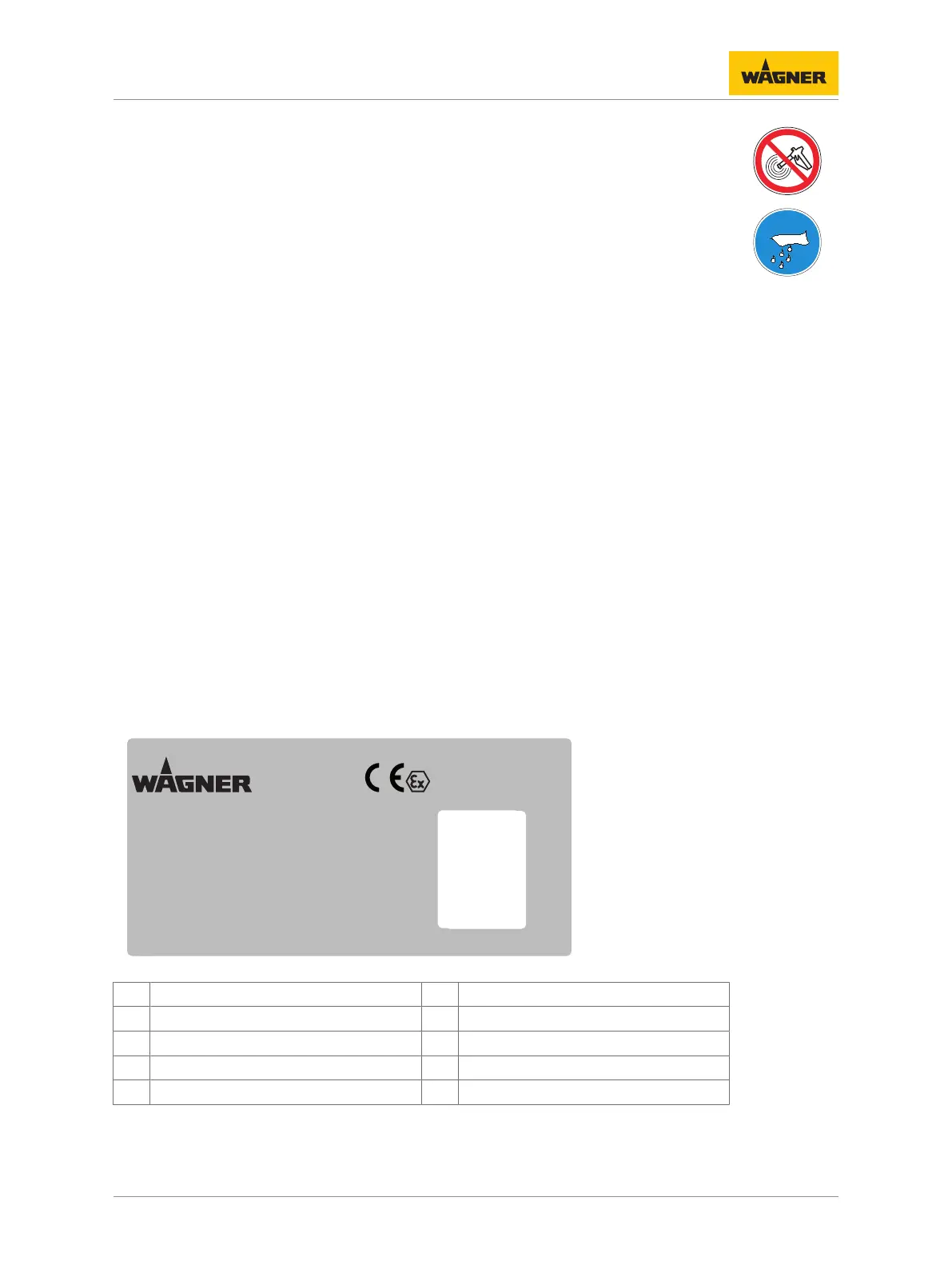

3.3 TYPE PLATE

1

2

4

5

6

7

8

9

3

B_06856

Pumpentyp / Pump type

Max.

Materialdruck / Fluid pressure

Übersetzungsverhältnis / Ratio

Fördermenge DH / Delivery DS

Max. Luftdruck / Air pressure

Max. Temp. Material / Fluid

Baujahr - Serie Nr. / Year of manufacture - Serial No.

Vor Gebrauch Betriebsanleitung beachten / Check manual before use!

Wagner International AG

MADE IN SWITZERLAND

CH-9450 ALTSTÄTTEN

II 2 G Ex h IIB T3/T4 Gb X

Example type plate

1 Manufacturer and CE identification 6 Maximum air inlet pressure

2 Pump type 7 Maximum product temperature

3 Maximum product pressure 8 Model year - serial number

4 Pump ratio 9 Read operating manual before use!

5 Flow rate per double stroke

Loading...

Loading...