Operating manual Piston Pump EvoMotion 5-125

7 Operation

34 Order number 2316596 | Edition 03/2021

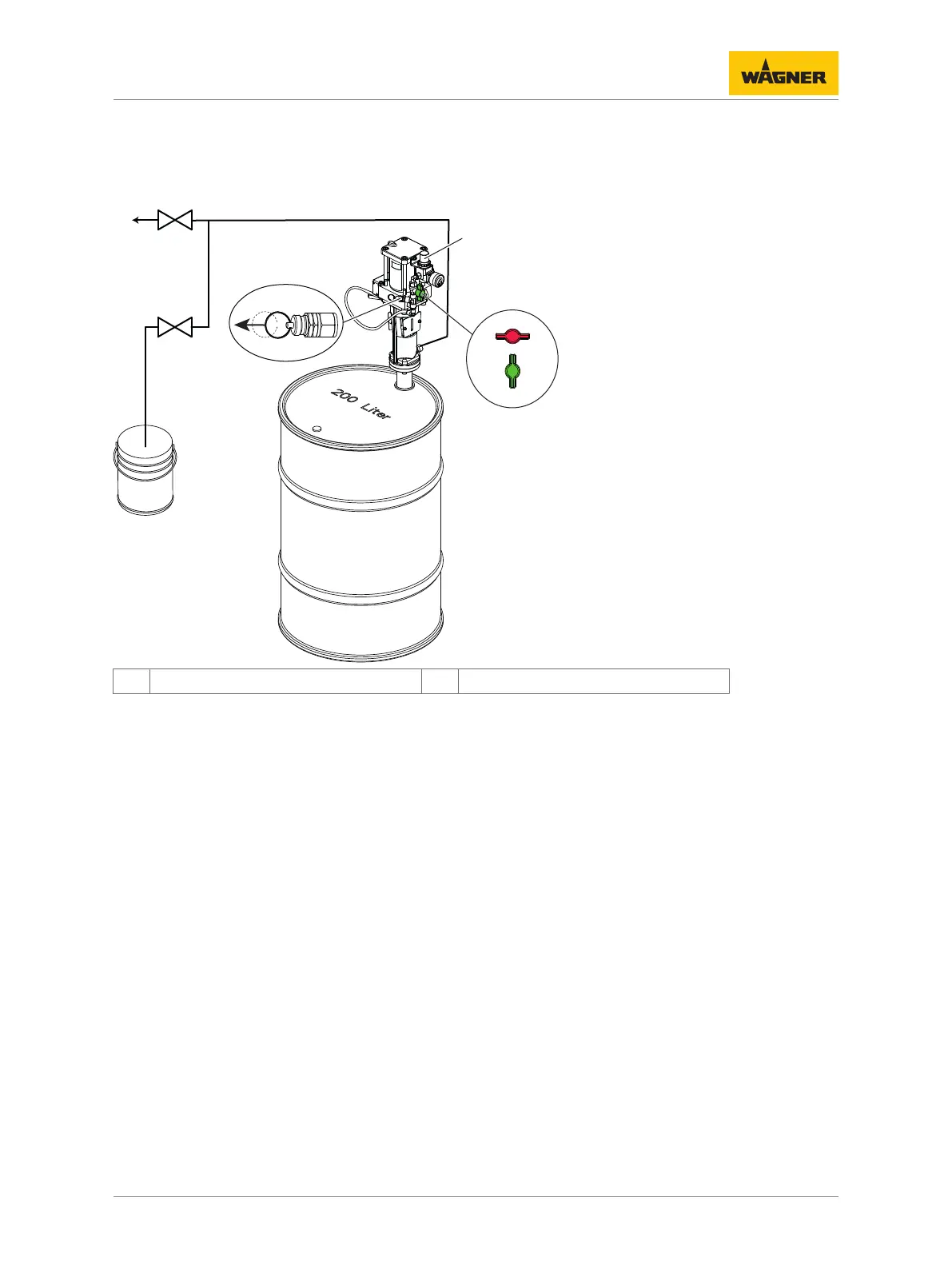

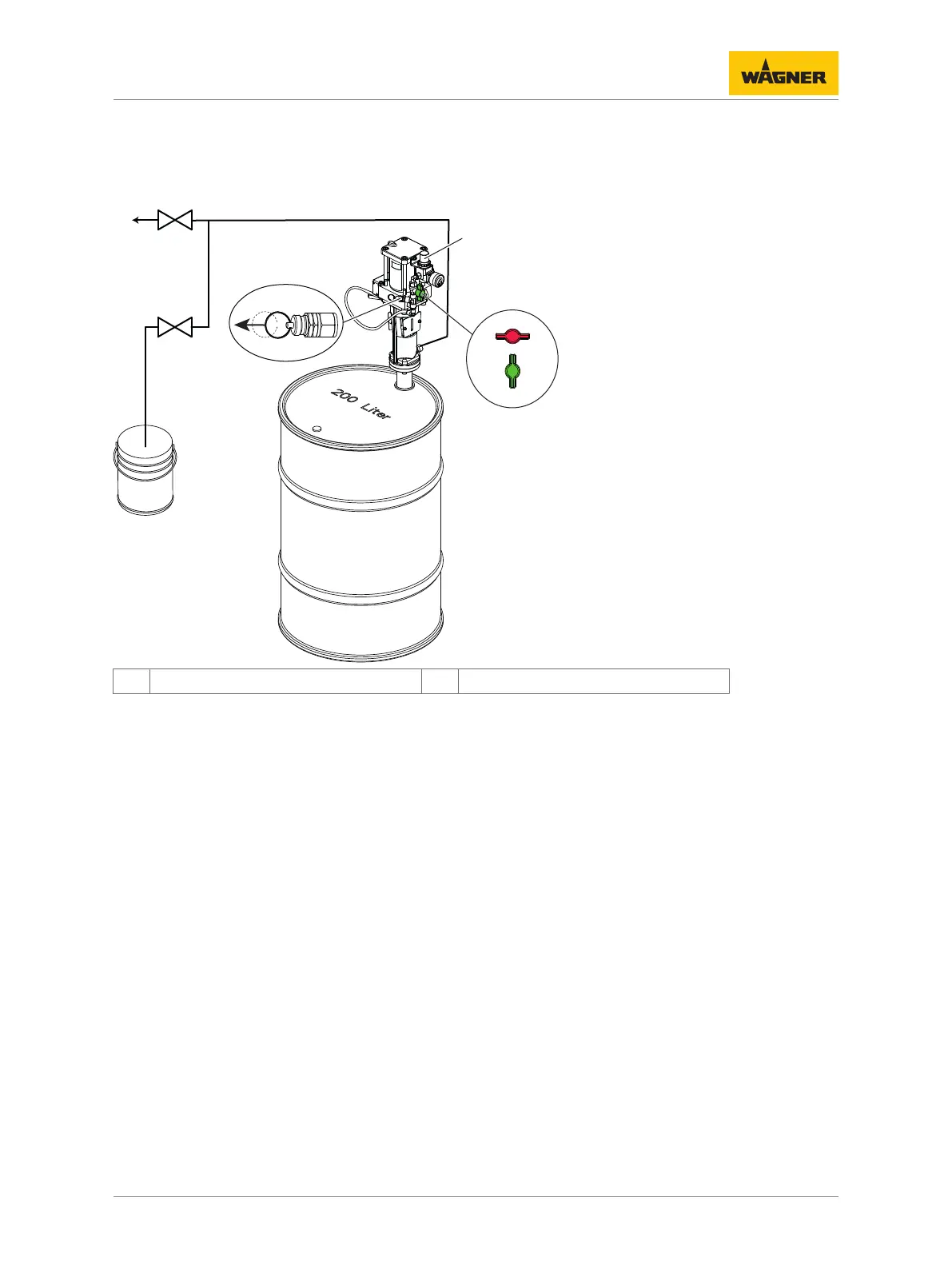

6. Open and close the valve (4) and/or the the lock units on the product line in order to

start and/or interrupt the product flow.

7. Start work process.

A closed B open

7.4 PRESSURE RELIEF / WORK INTERRUPTION

The pressure must always be relieved:

– after the spraying tasks are finished,

– before servicing or repairing the system,

– before carrying out cleaning tasks on the system,

– before moving the system to another location,

– before something needs to be checked on the system,

– before the nozzle or the filter is removed from the spray gun.

The components for pressure relief on a CE-compliant spraying system include:

– Air cock with pressure relief valve mounted between the compressed air source and the

pneumatic pump. In this case, the pressure relief valve is the safety valve (8).

– Outlet equipment (return valve) mounted between pump and spray gun.

Loading...

Loading...