71

Maintenance Instructions CHECKING/SERVICING

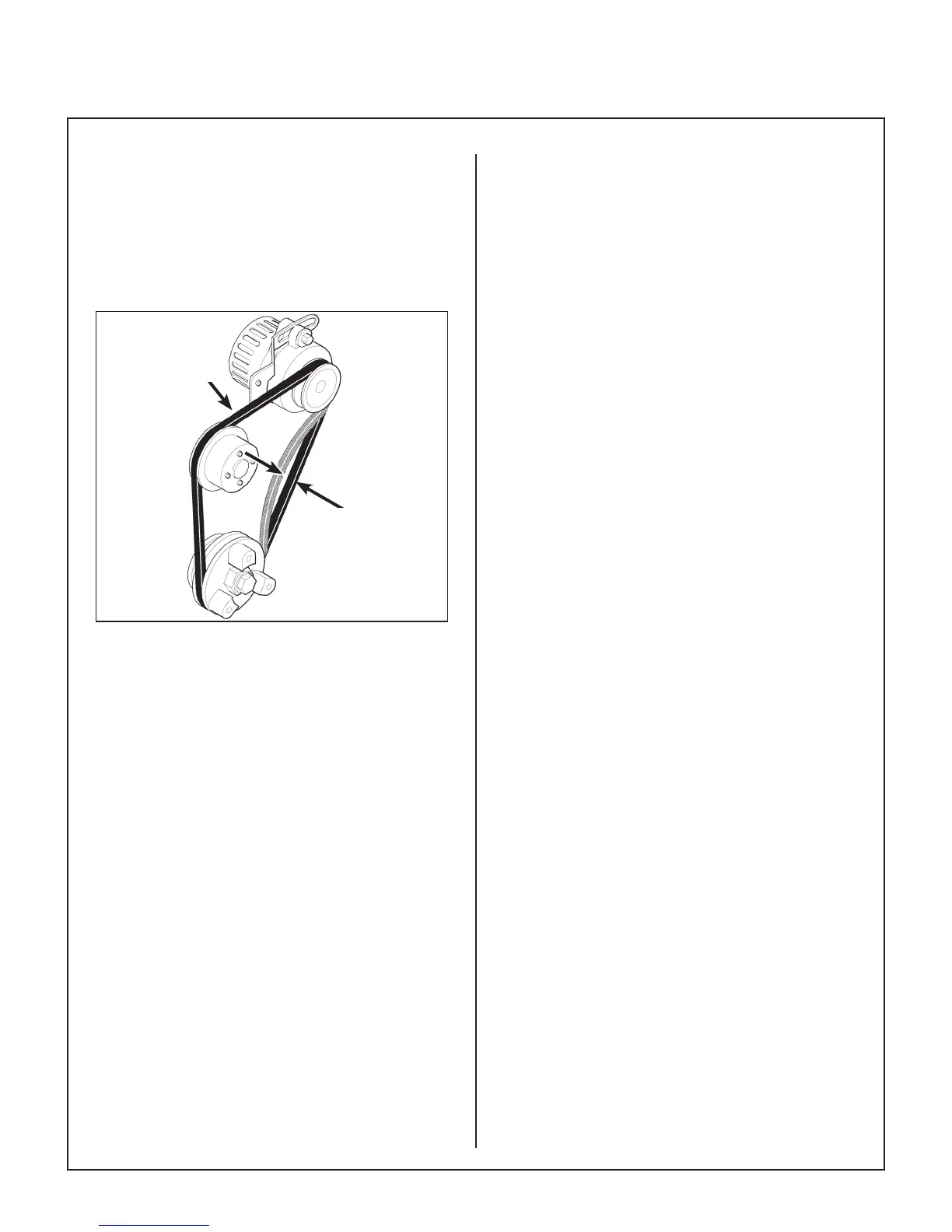

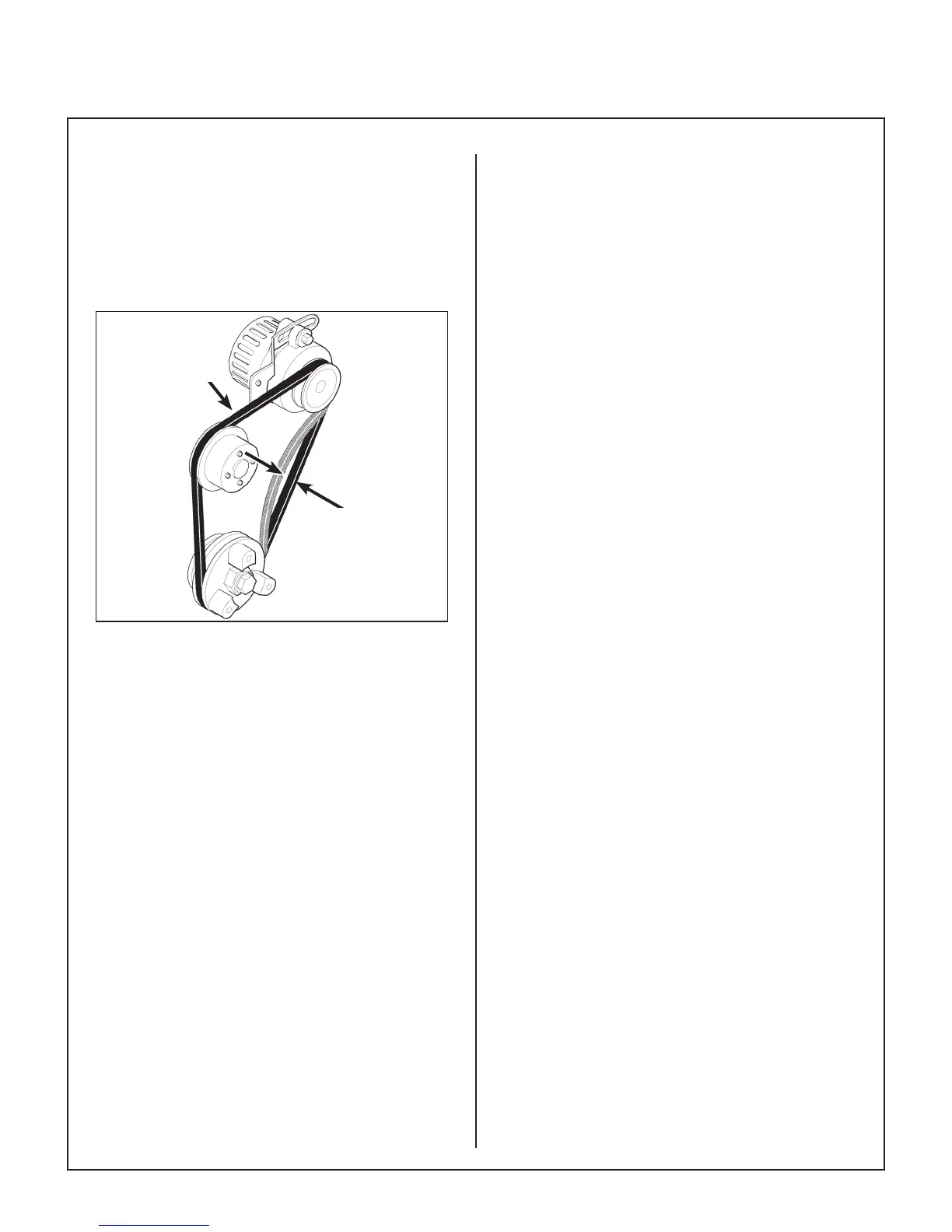

Alternator Belt Tension

Check and adjust the alternator belt tension to avoid

engine overheating and insucient battery

charging. Push on the belt in the middle of the span

between the alternator and crankshaft. If properly

tensioned, it should deect about 0.4 in. (10 mm).

Also check the belt for cracks or deterioration.

Alternator Belt

0.4 in. (10 mm)

Deection

Alternator Belt Tension

Security of Air Filtration Components

NOTE: The following inspection is only an exter nal

inspection and should be done without “dis-

turbing” the ltration components.

On a daily basis, visually inspect the external condi-

tion of the complete air cleaner system. The follow-

ing items should be inspected:

1. Check the Donaldson Radialseal™ air cleaner

canister for damage. Make sure the cover is in

place and the cover latches are secure—do not

run the engine without the air cleaner cover in

place and secure.

2. Inspect the air intake hose for cracks, nicks,

cuts, etc., and check the hose clamps for tight-

ness.

3. Check to make sure the air lter restriction

gauge is in place and hose connections are se-

cure.

Battery

NOTE: For initial battery service during setup, re fer

to Battery Service in Assembly Instructions.

IMPORTANT: Make sure battery is securely mount-

ed in the frame. A loose battery may cause damage

to the case resulting in acid leakage and severe

damage to the machine. A hazard may be created

by damage to critical working parts and safety sys-

tems.

Electrolyte Level

The battery electrolyte level should be checked af-

ter every 25 hours of operation. To check electro-

lyte level:

1. Remove battery cell ller caps.

2. Check the electrolyte level. If the level is below

the bottom of the vent well, ll with distilled wa-

ter to the bottom of the vent wells [1/4 to 1/2 in.

(6 to 13 mm) above the plates].

3. Replace ller caps.

IMPORTANT: DO NOT overll the battery. Electro-

lyte will overow through the vented caps onto parts

of the machine and WILL result in severe corrosion.

Cleaning the Terminals

If battery terminals are corroded, remove battery

from the mower. Using a wire brush, remove corro-

sion with a solution of one part baking soda and

four parts water. Rinse with clean water. Coat the

terminals with petroleum jelly or terminal protector

spray to retard further corrosion.

Loading...

Loading...