47

Maintenance Instructions LUBRICATION

3. Remove the dipstick, oil ll cap, and oil drain

plug, and drain the oil into a suitable container.

Be sure to allow ample time for complete

drainage.

4. Before removing the oil lter, clean the area

around the lter to keep dirt and debris out of

the engine.

5. Remove the old oil lter and wipe off the lter

mounting surface on the engine.

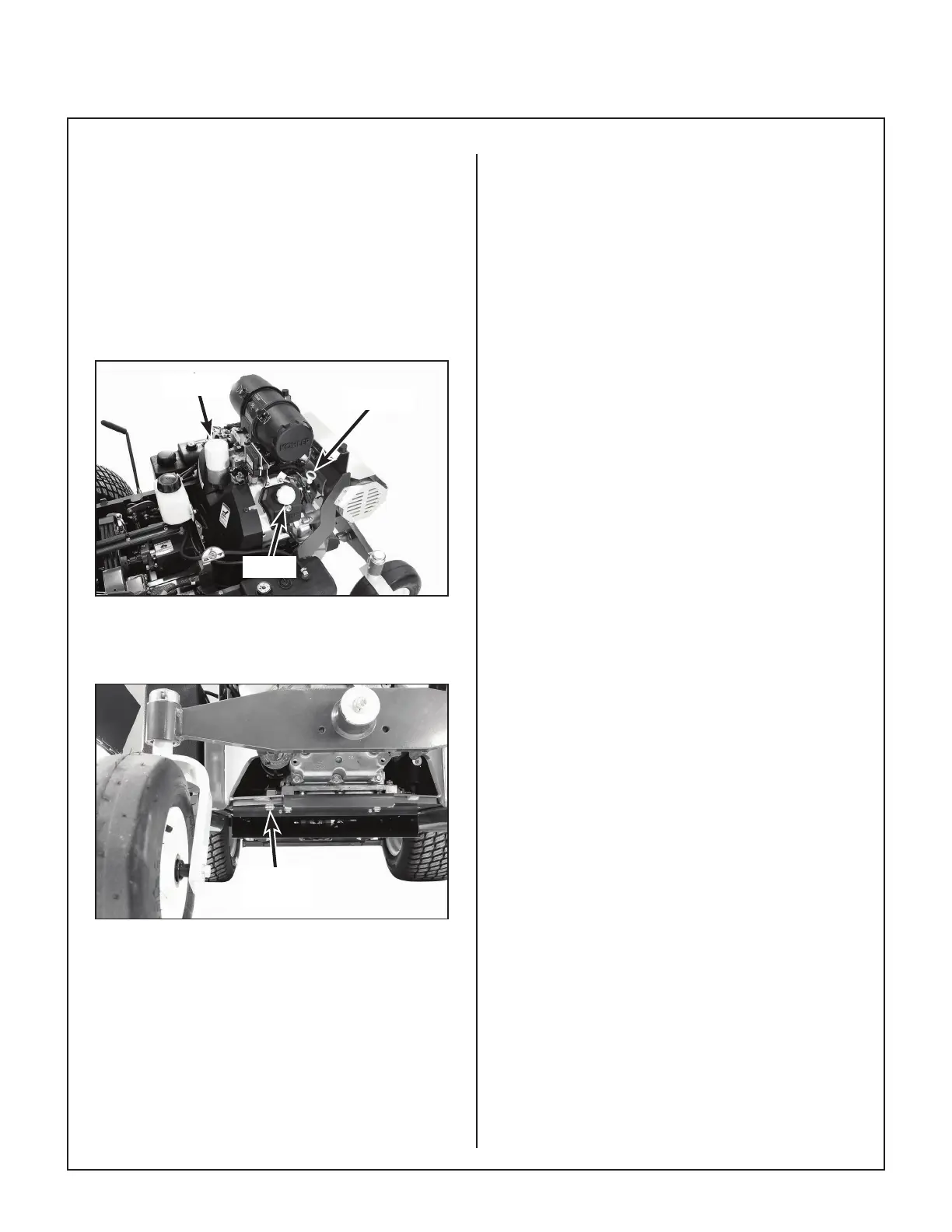

Oil Fill

Oil Filter

Dipstick

Dipstick, Oil Fill and Oil Filter Locations

(View from Above Left Side of Tractor)

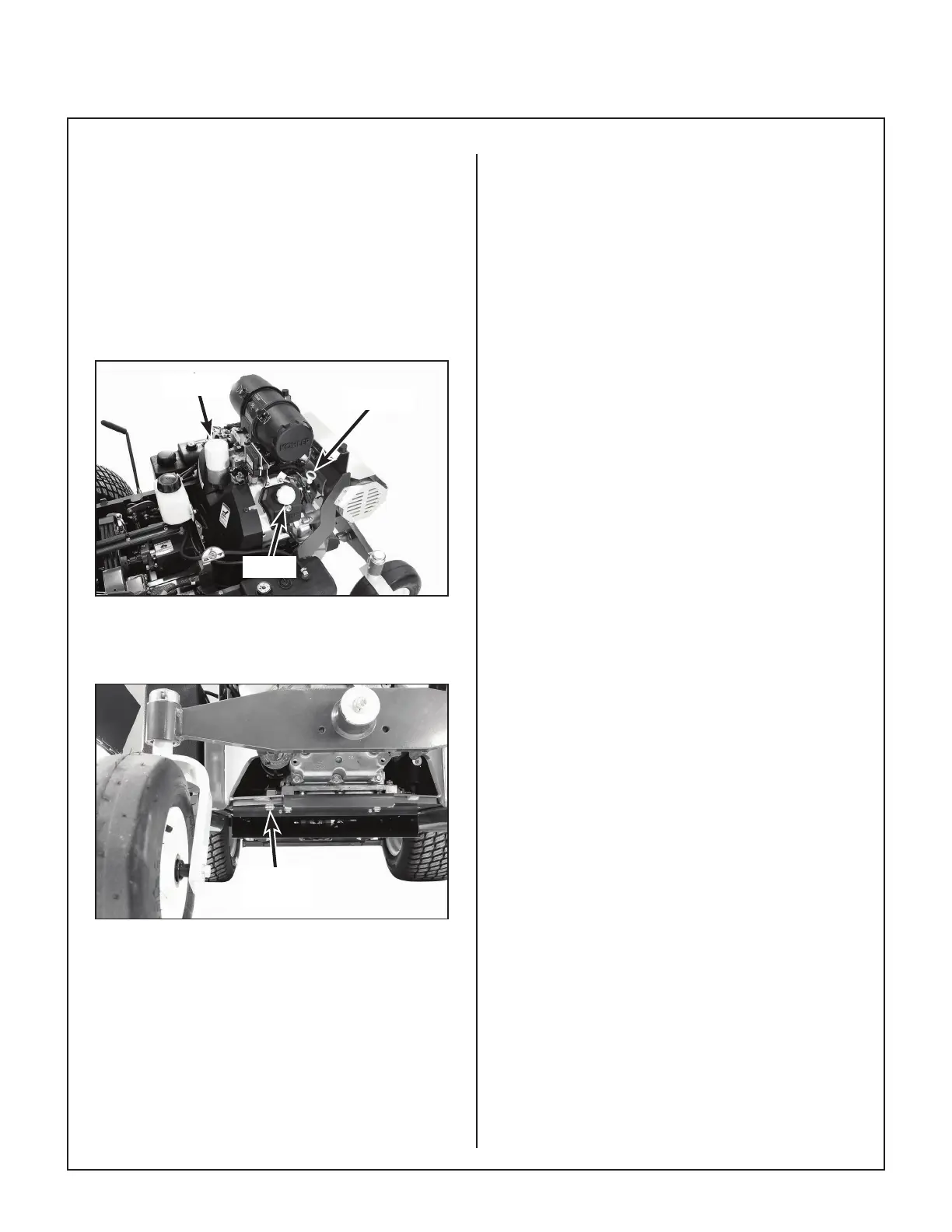

Oil Drain

Plug

Oil Drain Location

(View from Rear of Tractor)

6. Apply a thin coating of new oil to the rubber gas

ket on the replacement oil lter.

IMPORTANT: Use ONLY oil lters from the en

gine manufacturer (Kohler P/N 52 050 02). Af

termarket oil lters may not seal properly and/or

may not have the cor rect pressure relief valve

for proper lubrication.

7. Install the new oil lter on the engine. Turn the

lter clockwise until the rubber gasket con tacts

the sealing surface, then tighten an additional

2/3 turn.

8. Reinstall the drain plug. Make sure it is tight

ened to 10 lb·ft (14 N·m).

9. Fill the crankcase with new, clean oil. Use only

crankcase lubricants recommended by the en

gine manufacturer. Refer to Specications in

this manual or the engine owner’s manual. Use

the recommended oil viscosity for the expected

ambient temperature. Oil with the correct vis

cosity will aid starting in cold weather and as

sure proper lubrication in hot weather. Fill up

to, but not above the “F” mark on the dipstick.

Crankcase capacity is 2.0 quarts (1.9 liters)

when changing oil and lter.

IMPORTANT: Check the dipstick reading before

adding the last 1/2 pint of oil and ll only to the

“F” mark. The oil level should never be above the

“F” mark on the dipstick; overlling can result in

engine overheating, loss of power, and possible

engine damage.

10. Start the engine and check for oil leaks around

the oil lter. Stop the engine, recheck the oil

level, and add oil if necessary. (When the en

gine is rst operated with a new oil lter, the oil

level will drop slightly as the lter is lled with

oil.)

Mower Deck Spindle Lubrication

Lubricate each deck spindle grease tting every 25

hours. Use SAE general purpose lithium or molyb

denum base grease for grease ttings.

Loading...

Loading...