7.1.4 Pilot fuel pump

It is recommended to use lithium soap based EP-greases having a penetration of 300...350 when measured

according to ASTM D 217 standard and being classed as NLGI Grade 1 at 30...70°C operating temperature.

An updated list of approved oils is supplied for every installation.

7.2 Internal lubricating oil system

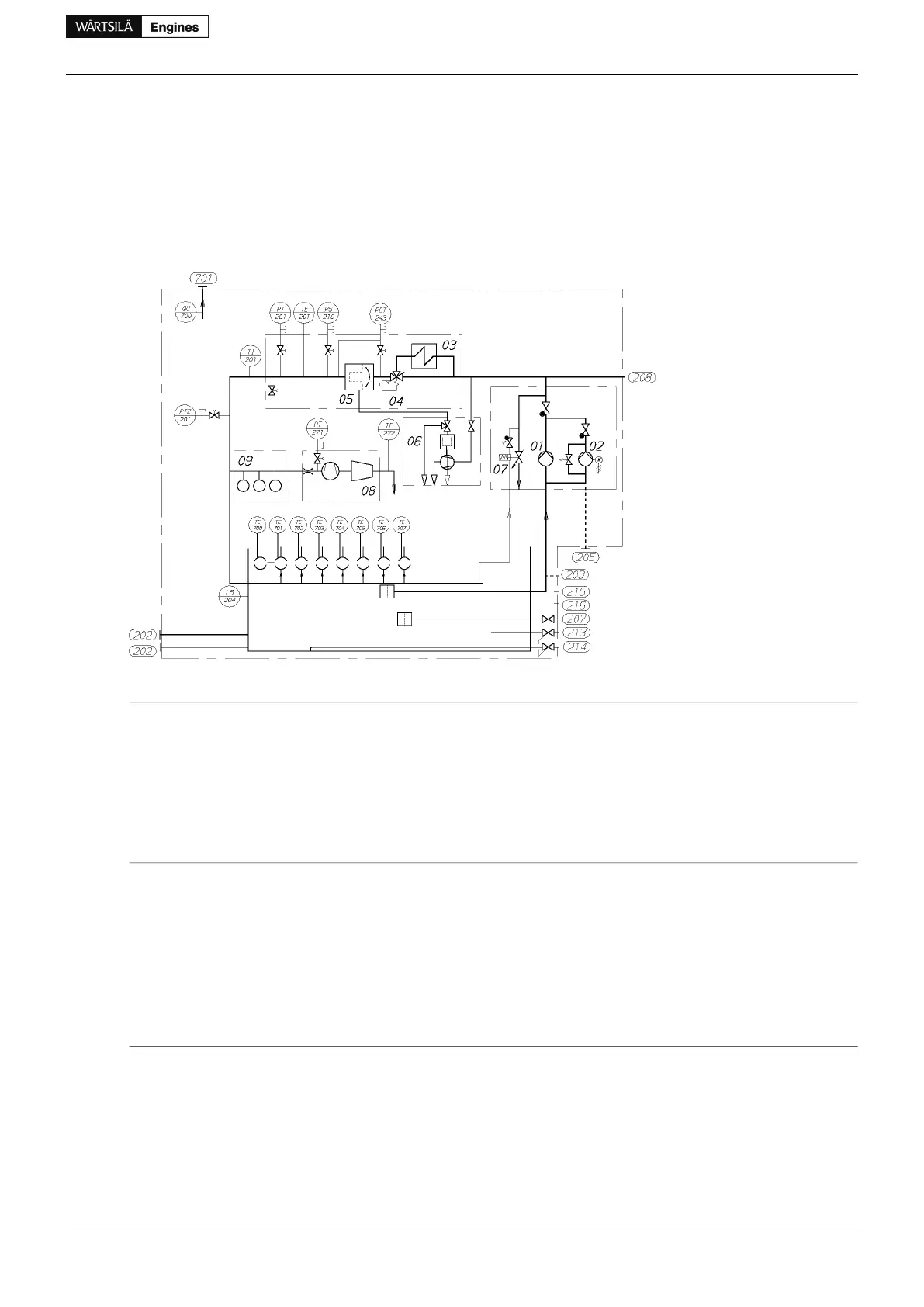

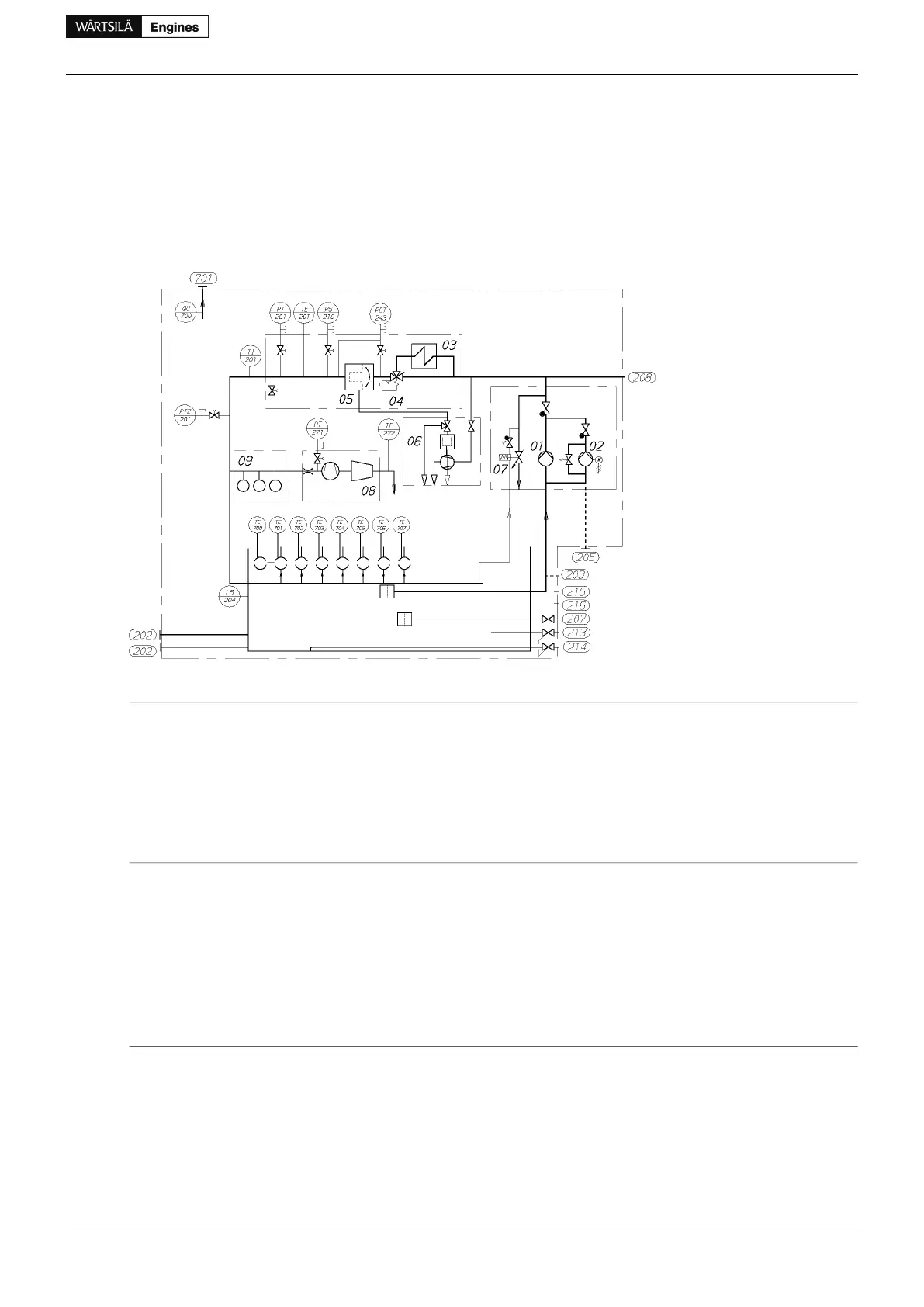

Figure 7.1 Internal lubricating oil system, in-line engines (DAAE055611a)

System components:

Centrifugal filter06Lubricating oil main pump01

Pressure control valve07Prelubricating oil pump02

Turbocharger08Lubricating oil cooler03

Camshaft bearings and cylinder head lubrication09Thermostatic valve04

Automatic filter05

Sensors and indicators:

Lubricating oil pressure, TC inletPT271Lubricating oil pressure, engine inletPT201

Lubricating oil temperature, TC outletTE272Lubricating oil pressure, engine inletPTZ201

Oil mist detectorQU700Lubricating oil temperature, engine inletTE201

Lubricating oil temperature, engine inlet (if ME)TI201Lubricating oil low level (wet sump)LS204

Main bearing temperatureTE7##Lub. oil stand-by pump start (if stand-by pump)PS210

Lubricating oil filter pressure differencePDT243

StandardPressure classSizePipe connections

ISO 7005-1PN16DN150Lubricating oil outlet (dry sump)202

ISO 7005-1PN16DN200Lubricating oil to engine driven pump (dry sump)203

ISO 7005-1PN16DN80Lubricating oil to priming pump (dry sump)205

ISO 7005-1PN16DN150Lubricating oil to el.driven pump (stand-by pump)207

ISO 7005-1PN16DN100Lubricating oil from el.driven pump (stand-by pump)208

ISO 7005-1PN40DN40Lubricating oil from separator and filling (wet sump)213

ISO 7005-1PN40DN40Lubricating oil to separator and drain (wet sump)214

Product Guide Wärtsilä 34DF - 3/2012 69

Product Guide

7. Lubricating Oil System

Loading...

Loading...