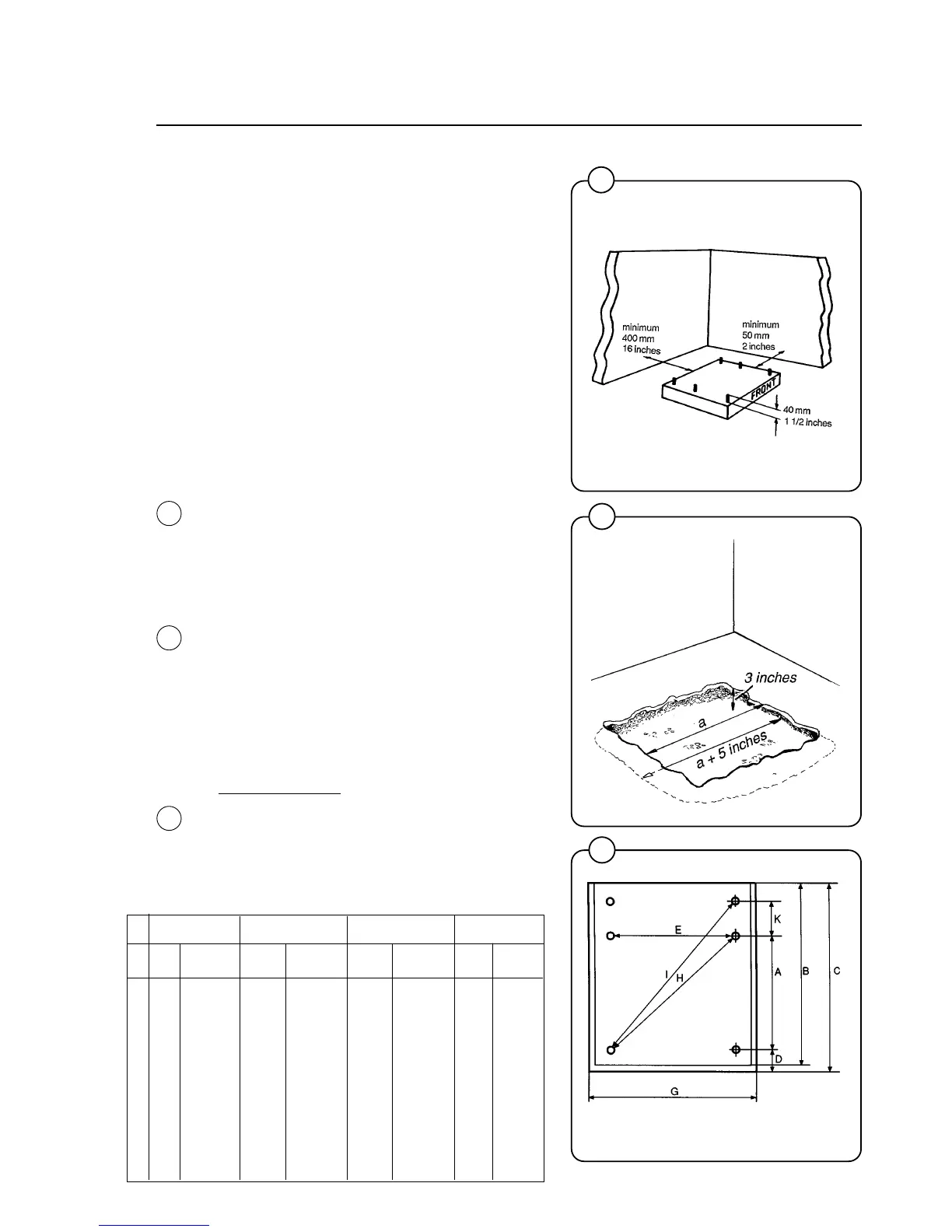

W75 W105 W125 W185

mm inches mm inches mm inches mm inches

A 364 14 11/32 481 18 15/16 508 20 600 23 2/3

B 593 23 11/32 710 27 15/16 910 35 13/16 960 37 3/4

C 648 25 1/2 760 29 15/16 1031 40 9/16 1078 42 7/16

D 100 4 100 4 142 5 9/16 142 5 9/16

E 530 20 7/8 530 20 7/8 600 23 5/8 700 27 9/16

G 700 27 9/16 700 27 9/16 800 31 1/2 880 34 2/3

H 643 25 5/16 715,6 28 3/16 786 30 15/16 922 36 1/8

I - - - - 991 39 1090 42 7/8

K - - - - 281 11 236 9 7/16

Installation

2

3

4

0271

1677

1132

Installation

Machine foundation

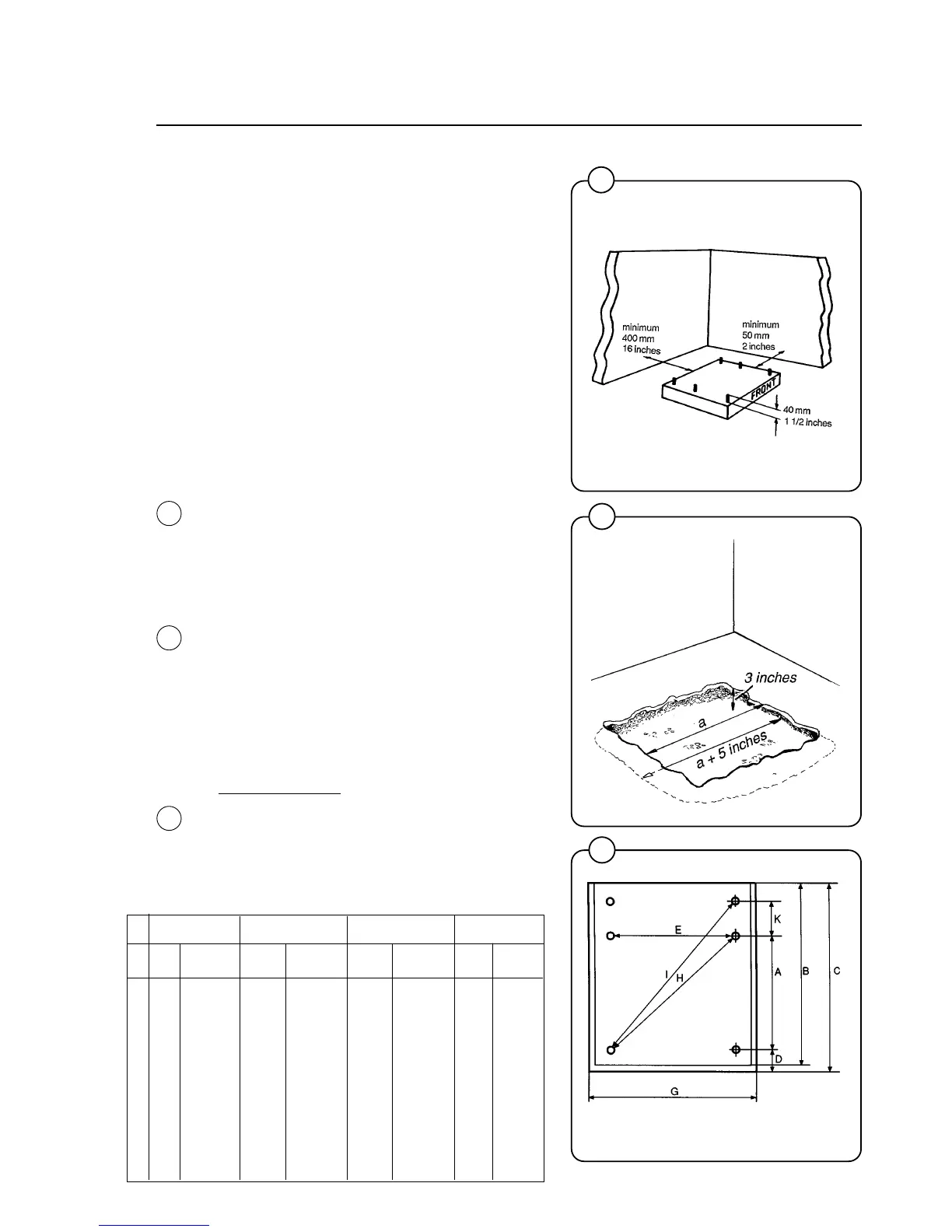

The machines are designed to be securely bolted

to a concrete pad. A template showing the size of

the pad and positioning of the bolts is delivered

with each machine.

For installation on an existing concrete floor, the

floor must be at least 8" thick and of good quality.

If the floor does not meet these requirements,

then a 6-8" high concrete pad should be made. A

prefabricated steel base is available for mounting

machines without pouring a pad.

Follow the instructions below when making a

concrete foundation:

1. Decide where to place the machine and

consider maintenance requirements, i.e.

determine a suitable distance from the rear of

the pad to the wall, and the distance from the

pad to the nearest side wall. The distance

should be at least 16 and 12 inches,

respectively. Leave 3/4'' between washers.

2. Break up the floor to a minimum depth of 3

inches, making sure that the sides of the hole

slope away - the bottom of the hole should be

5 inches longer than the upper length.

3. Wet the hole well. Brush the bottom and sides

with cement grout.

4. Prepare a casing and fill with 3.000 PSI

concrete to form pad. Make sure the

foundation is level.

5.

Use the template to position the bolts

correctly. Bolts are to extend 1 1/2" above the

concrete.

NOTE: A prefabricated steel frame, designed

to be placed in the concrete instead of the

individual mounting bolts, is available.

7

Fig.

2

Fig.

3

Fig.

4

B = machine outline to edge of front panel

C, G = minimum foundation for one machine

Loading...

Loading...