Rinse Thermostat

Part Number

3020

Function

Controls the rinse heating elements and prevents operation of machine if the rinse

temperature is below that required.

Description

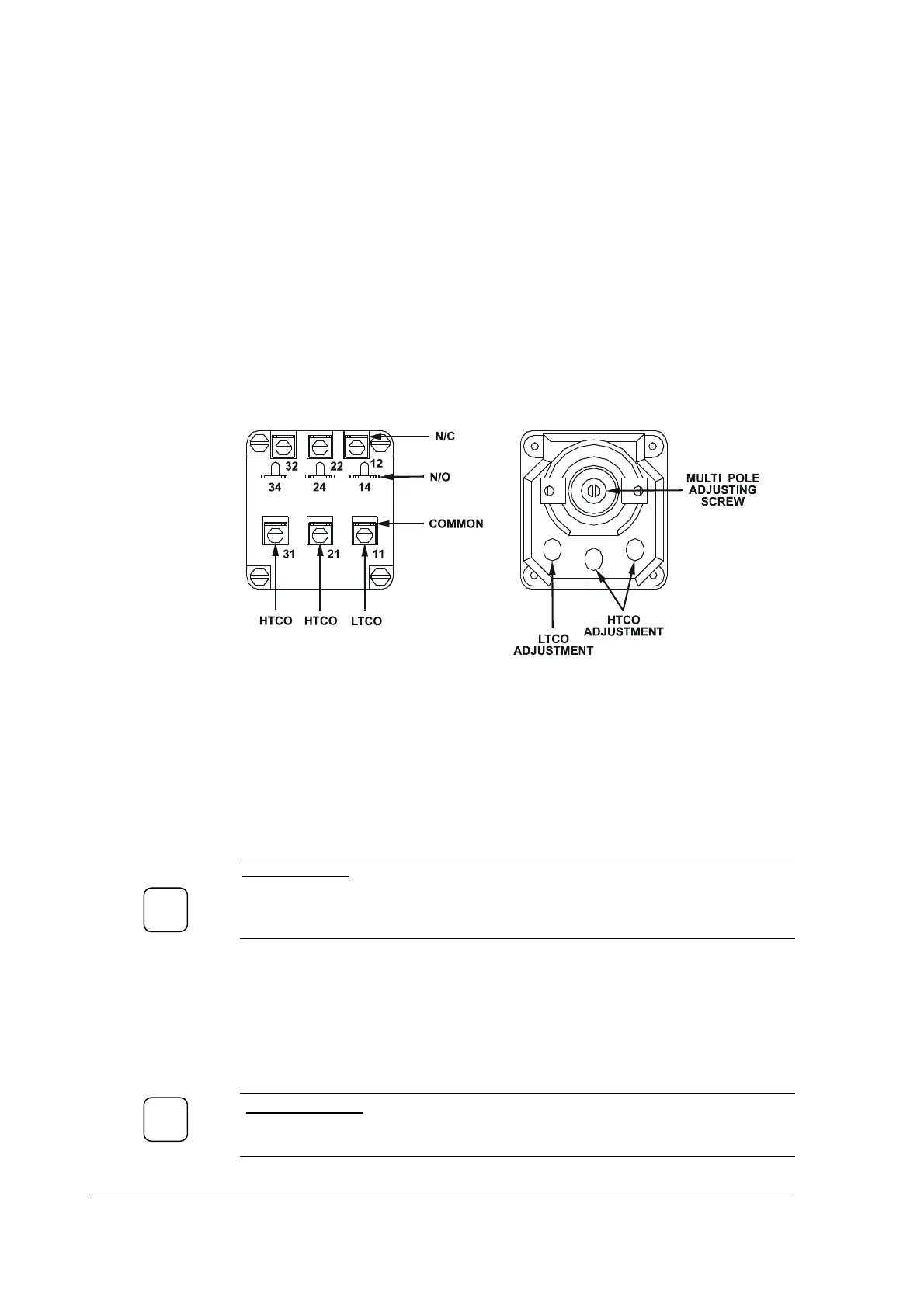

The rinse thermostat is a specially calibrated 3 pole capillary type temperature operated

device. The thermostat does not have a control knob and it is factory set to the

temperatures required by Hygiene Regulations. The first pole’s LTCO changeover contact

is set to operate at 83 ±3°C, the other two poles HTCO contacts are set to 90±3°C.

Switching capacity: 16(4) A 380 V.

Diagrams

LTCO – Low Temp Cut Out

HTCO – High Temp Cut Out

Replacement

Take note of the connections to the wiring loom before disconnecting. Remove the

capillary bulb from the rinse tank pocket. Select a new thermostat and carefully unwind

enough capillary to reach from the pocket to the thermostat mounting position. Carefully

position the tube with no kink or stress on the tube, also have due regard for the protection

of the tube against contact with live electrical terminals – secure or insulate as appropriate.

Adjustment

IMPORTANT

To make adjustments to the thermostat you will need a good quality thermometer

fitted with a “type K” thermo junction. The use of a stainless steel probe is not

permitted as slow response time in the device will cause inaccurate settings.

Insert the thermo junction into the rinse tank pocket for the machine’s temperature gauge.

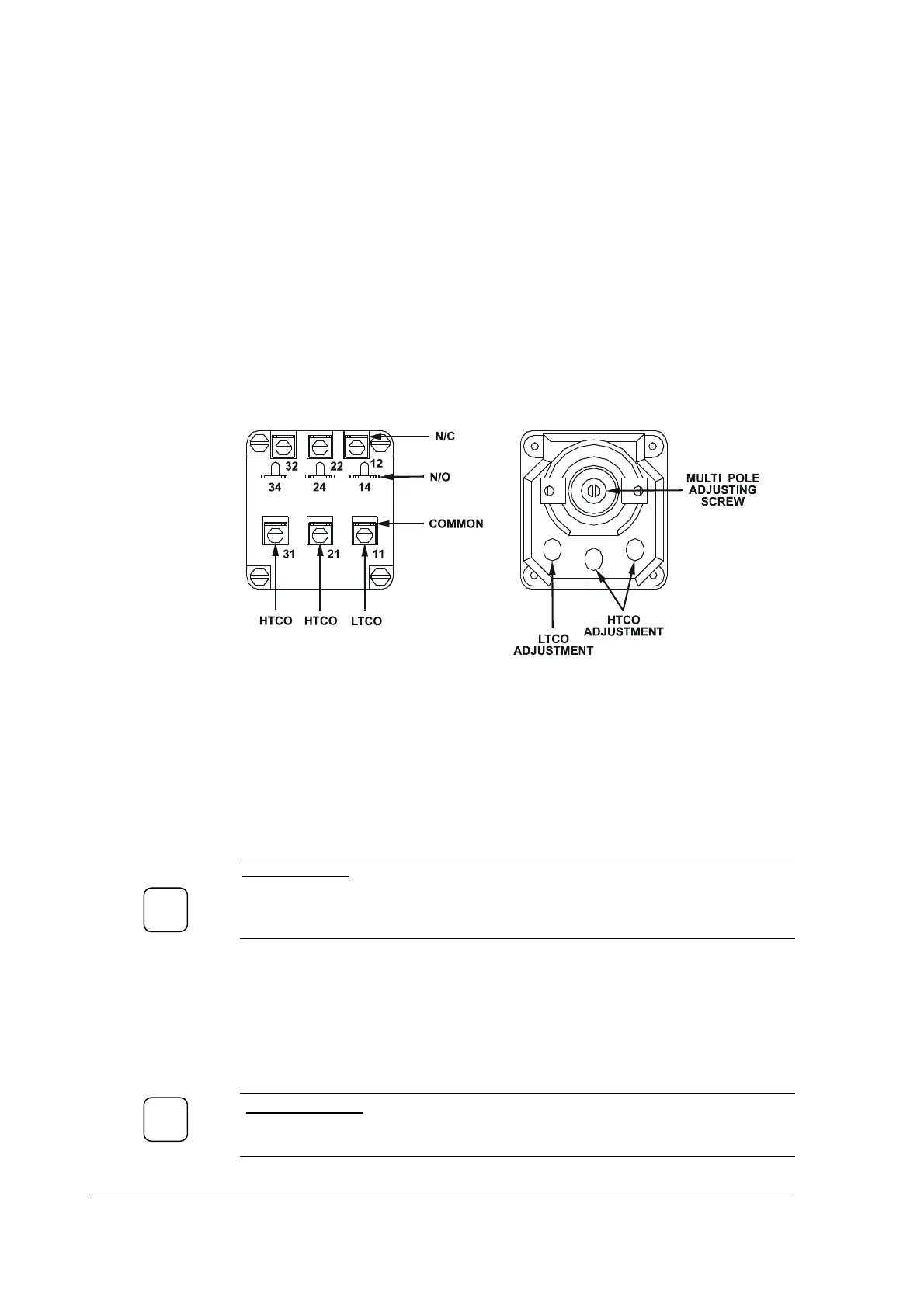

Energize the elements and check all temperatures on temperature rise. Remove the grey

tape covering three adjusting screws and adjust LTCO and HTCO settings if required (one

or both HTCO poles are used depends on model – check which HTCO terminals are

wired before making adjustments). Clockwise rotation of the screws increases the setting,

anticlockwise – decreases it.

IMPORTANT

Do not break the seal or attempt to adjust the central MULTI POLE

ADJUSTING SCREW that is sealed with red compound.

!

!

Loading...

Loading...