CHAPTER 3 - INSTALLATION AND CONNECTION

22

English

3.2.7 Control

and Signal

Connections

3.3 RECOMMENDED

SET-UPS

EMI - Electronic Interference

The Soft-Starter SSW-07 is developed to be used in industrial

systems (Class A) according to Standard EN60947-4-2.

It’s necessary to have a distance of 0.25 m (10 in) between the

Soft- Starter SSW-07 control cables and motor cables.

Example:PLCwiring,temperaturecontrollers,thermocouplecables,

etc.

Grounding of the Motor frame

Always ground the motor frame. The Soft-Starter SSW-07 output

wiring to the motor must be installed separately from the input wiring

as well as from the control and signal wiring.

The control connections (digital inputs and relay outputs) are made

throughtheterminals(refertogure3.9).

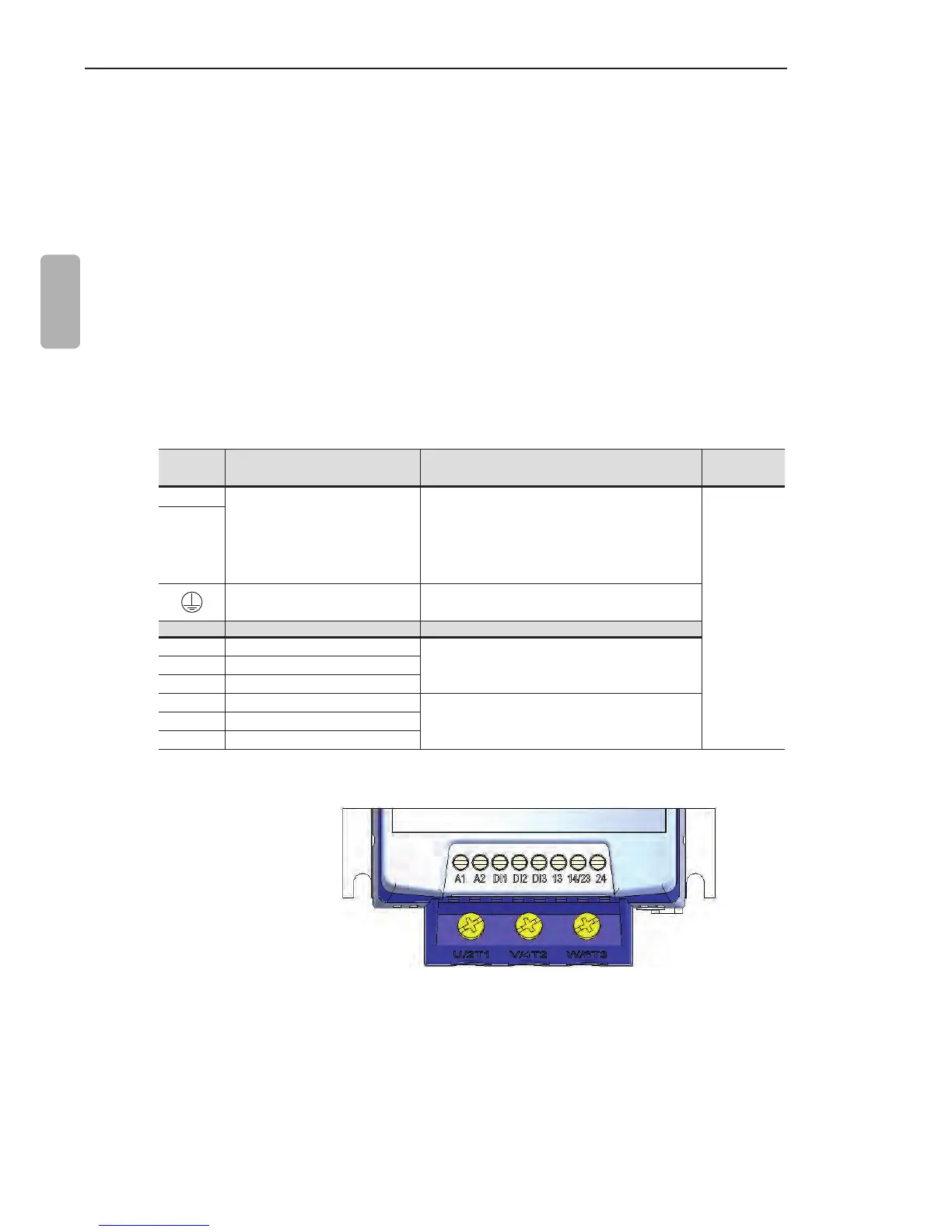

Terminal Description Specications

Torque Nm

(in lb)

A1

Electronics Supply

Voltage:110to240Vac(-15%to+10%)

(models from 17 A to 200 A)

110 to 130 Vac or 208 to 240 Vac

(-15%to10%)(modelsfrom255A

to 412 A).

0.5 (4.5)

A2

Grounding Only for the 255 to 412 A models

Terminal Factory Default Specications

DI1 Starts/Stops Motor

3 isolated digital inputs

Voltage:110to240Vac(-15%to+10%)

Current:2mAMax.

DI2 Fault reset

DI3 Fault reset

13 Relay 1 output - Operation

Contactcapacity:

Voltage:250Vac

Current:1A

14/23 Relay common point

24 Relay 2 output - Full voltage

Table 3.9 - Description of the control connector pins

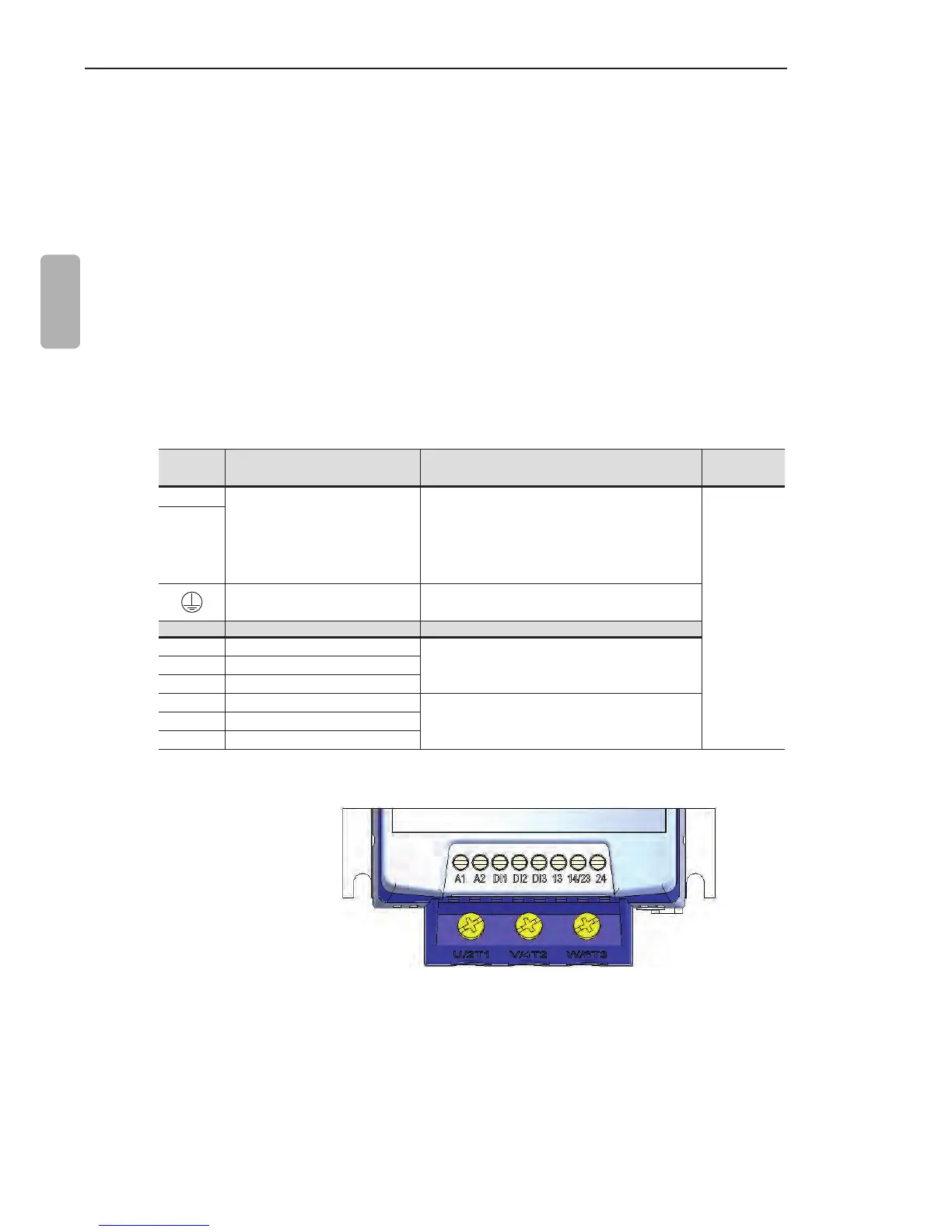

Figure 3.9 - Control terminals of the Soft-Starter SSW-07

Some recommended set-ups are shown here and they can be

completely or partly used.

The main warning notes for all the recommended set-ups are

shown below and are described in the schemes by their respective

numbers.

Loading...

Loading...