31

ENGLISH

11 Maintenance and servicing

11.5 Changing the V-belt | Tensioning the V-belt

The V-belt can be changed easily and without tools. To do this, tilt the

machine backwards so that the underside of the machine is clearly vis-

ible. Important: the cleaning start lever must not be pulled. Now the belt

can be pulled out of the pulleys, past the guides. When inserting the new

belt, make sure that it is guided exactly like the old belt. It is especially

important that the belt is centred in the tensioner pulley so that it works

properly.

Now lever the V-belt out of the groove from the bottom upwards (possibly

with the help of a screwdriver). Turn the brush element so that the V-belt

slides completely upwards out of the groove.

Drive belt designation: XPA 1220

Please use original belts from an authorised dealer only.

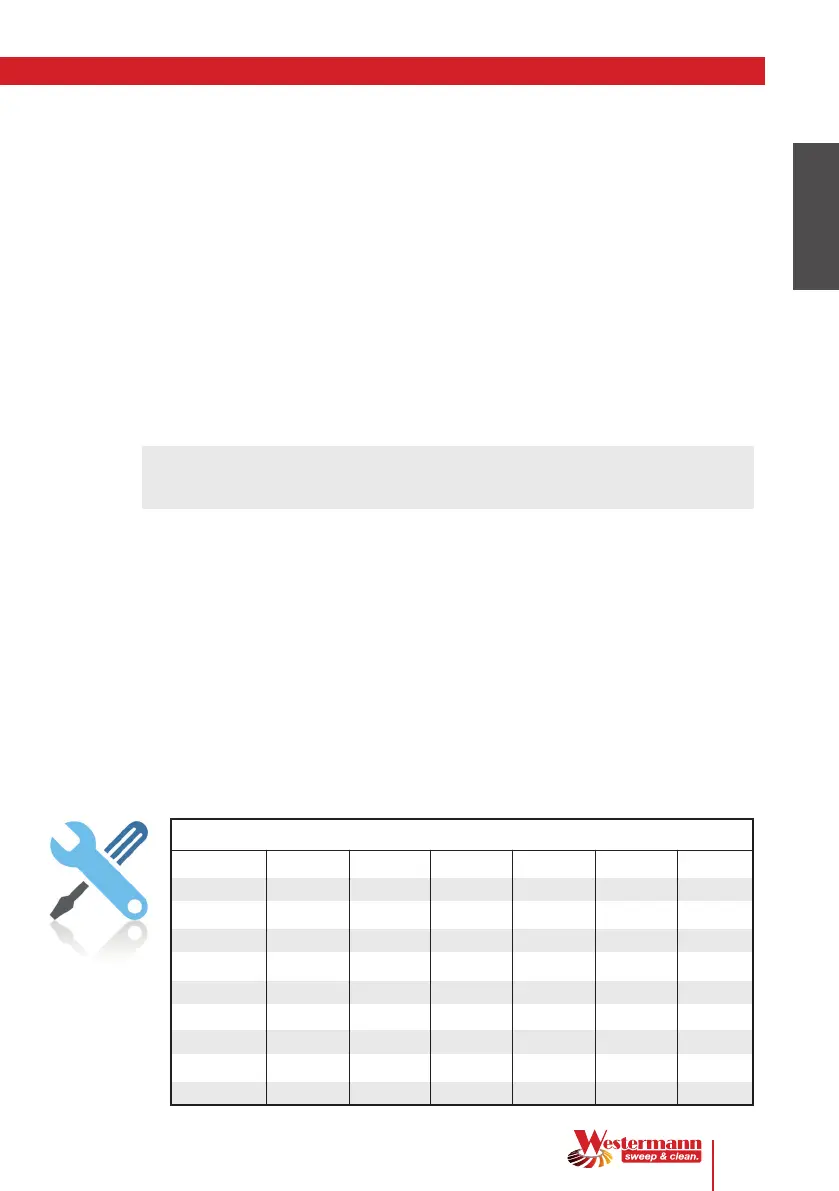

11.6 Screw ttings

Checkboltsandnutsfortightnessaftervehoursofoperationforthe

rsttime,thenregularly(every50hours)andretightenifnecessary.

• All torques TA are standard values for standard metric threads

according to DIN. Coefcient of friction 0.14 - new screws -

unlubricated. These values have been recommended as standard

values by various screw manufacturers. We cannot assume any

liability for the application.

• Self-locking nuts must be replaced after each disassembly.

Thread 3.6 5.6 6.8 8.8 10.9 12.9

M6 3.43 4.51 8.73 10.3 14.71 17.65

M8 8.24 10.79 21.57 25.50 35.30 42.17

M10 16.67 21.57 42.17 50.01 70.61 85.32

M12 28.44 38.25 73.55 87.28 122.58 147.10

M14 45.11 60.80 116.70 135.27 194.17 235.36

M16 69.63 93.16 178.46 210.84 299.10 357.94

M18 95.13 127.40 245.17 289.30 411.88 490.34

M20 135.33 180.44 348.14 411.88 576.50 669.26

M22 162.40 245.17 470.72 558.98 784.45 941.44

Torque for screwls TA

Loading...

Loading...