Page 24 | 1-800-343-9463

PS 020713

Measure Superheat

If superheat is high and bubbles are present, add more refrigerant until it is clear. If superheat is low (around 4-6

degrees Fahrenheit) and bubbles are present in the sight glass, check for liquid refrigerant entering the compressor

as evidenced by cool crankcase below 100- 110 degrees Fahrenheit and low discharge superheat. Adjust TXV setting

in small increments to increase superheat and stop liquid from going to the compressor. Check this before adding

more refrigerant. If the temperature of the air entering the condenser is cold enough to cause the condenser fan to

cycle, block about 60% of the coil to raise the head pressure and allow time for stabilization. Reduce blockage if the

condensing temp is above 115 degrees Fahrenheit. Retain blockage if necessary to maintain stability for performance

test listed in the Split System Warranty Checklist. If the air is cold, below 60 degrees Fahrenheit entering the condenser

and the sight glass is clear; allow the system to run for a while until the cellar cools o, then measure and record data

on the Split System Warranty Checklist.

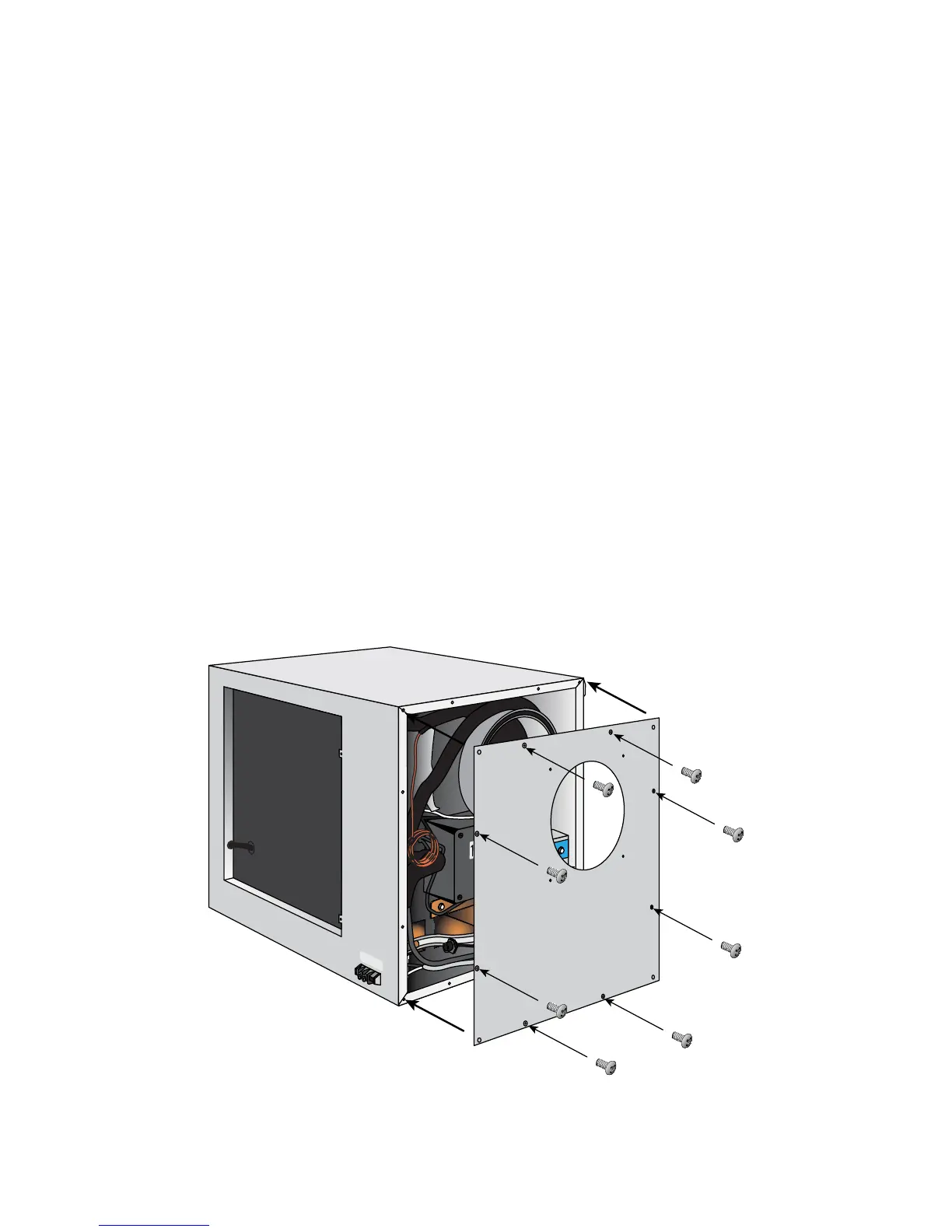

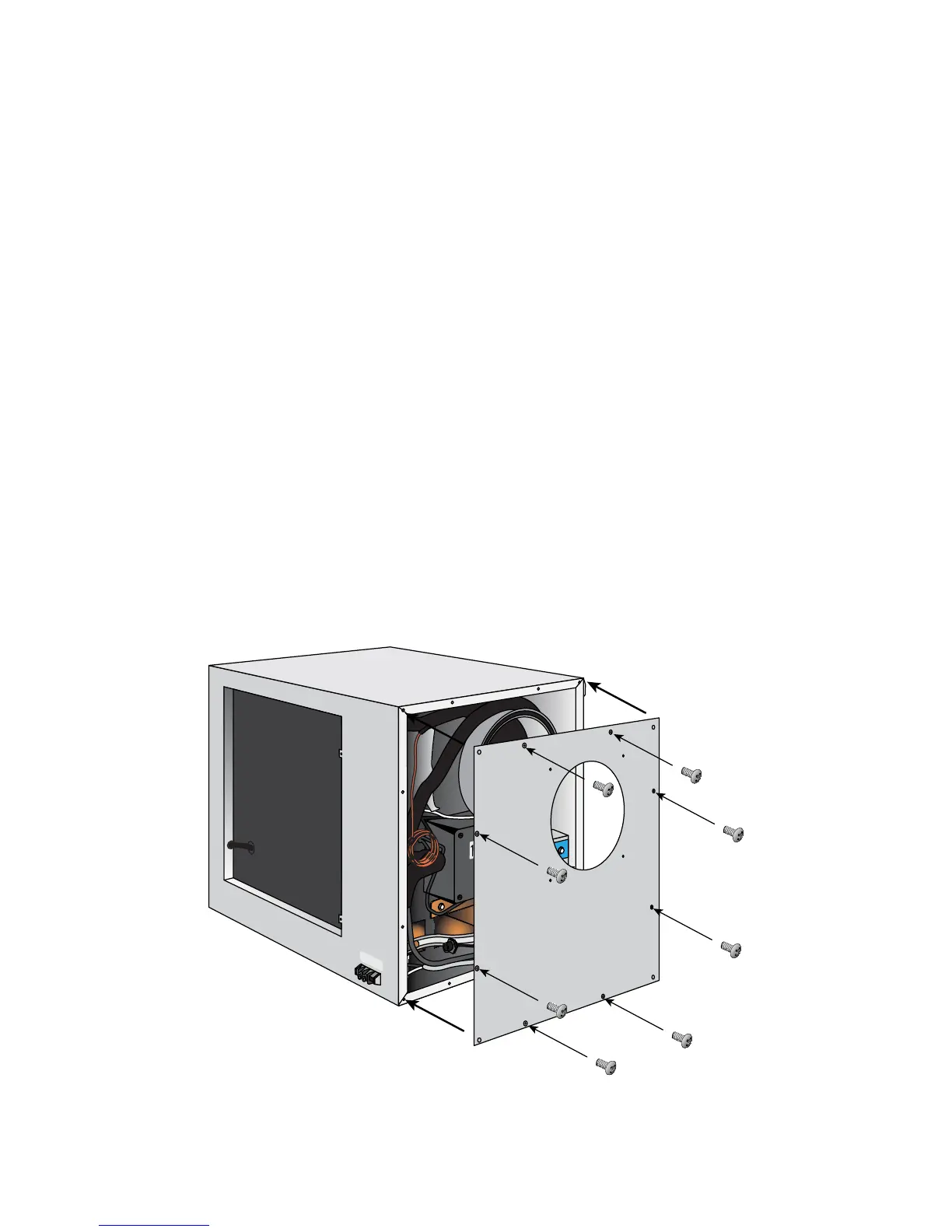

Reinstalled the Evaporator Unit (Fan Coil Unit) panel that was removed in step (10) on page 10. Conrm the controller

is displaying the correct temperature and that the controller is not displaying an alarm. If the controller is displaying

an alarm reference page 34 for corrective action. Conrm that the suction line is completely insulated, from TXV to

compressor. Conrm that the sight glass has no bubbles and the ambient temperature around the condensing unit is

not getting excessively hotter. Conrm that both king valves have been back seated and the nuts have been installed

back on the king service ports.

Secure the Side Panel by installing the eight Phillips head screws around the parameter of the side panel.

INSTALLING THE CONDENSING UNIT (continued)

BEFORE INSTALLING THE WALL MOUNT KIT OR DUCTED CONFIGURATION OPTIONS

Loading...

Loading...