PAGE 10

Adjusting the Tensions for Properly Balanced Stitching

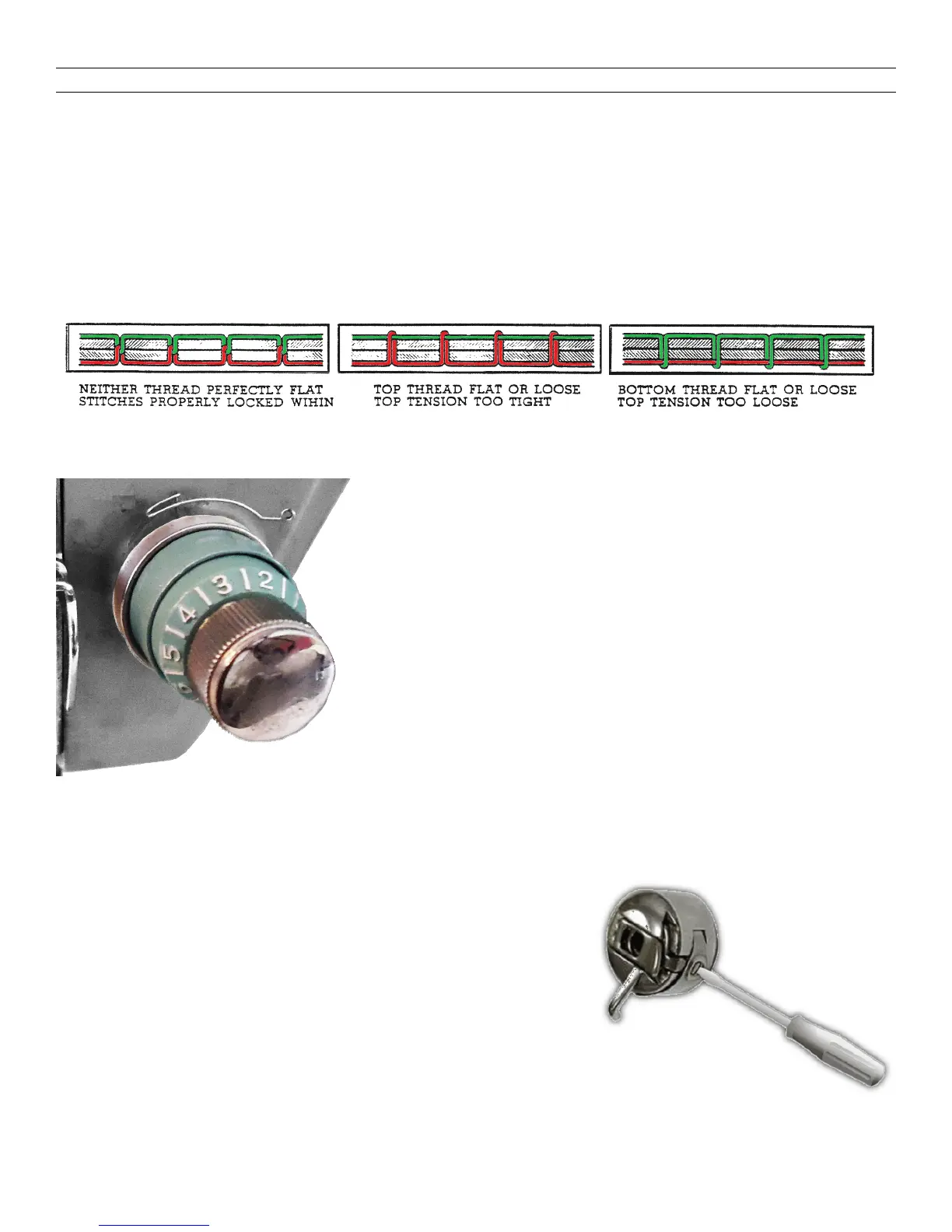

The shaded portions of the drawings below represent the fabric enlarged many, many

times to illustrate the lock-stitch principle — how and where both threads should

entwine WITHIN the fabric thickness.

Hold the finished side of the material upward when inspecting stitching.

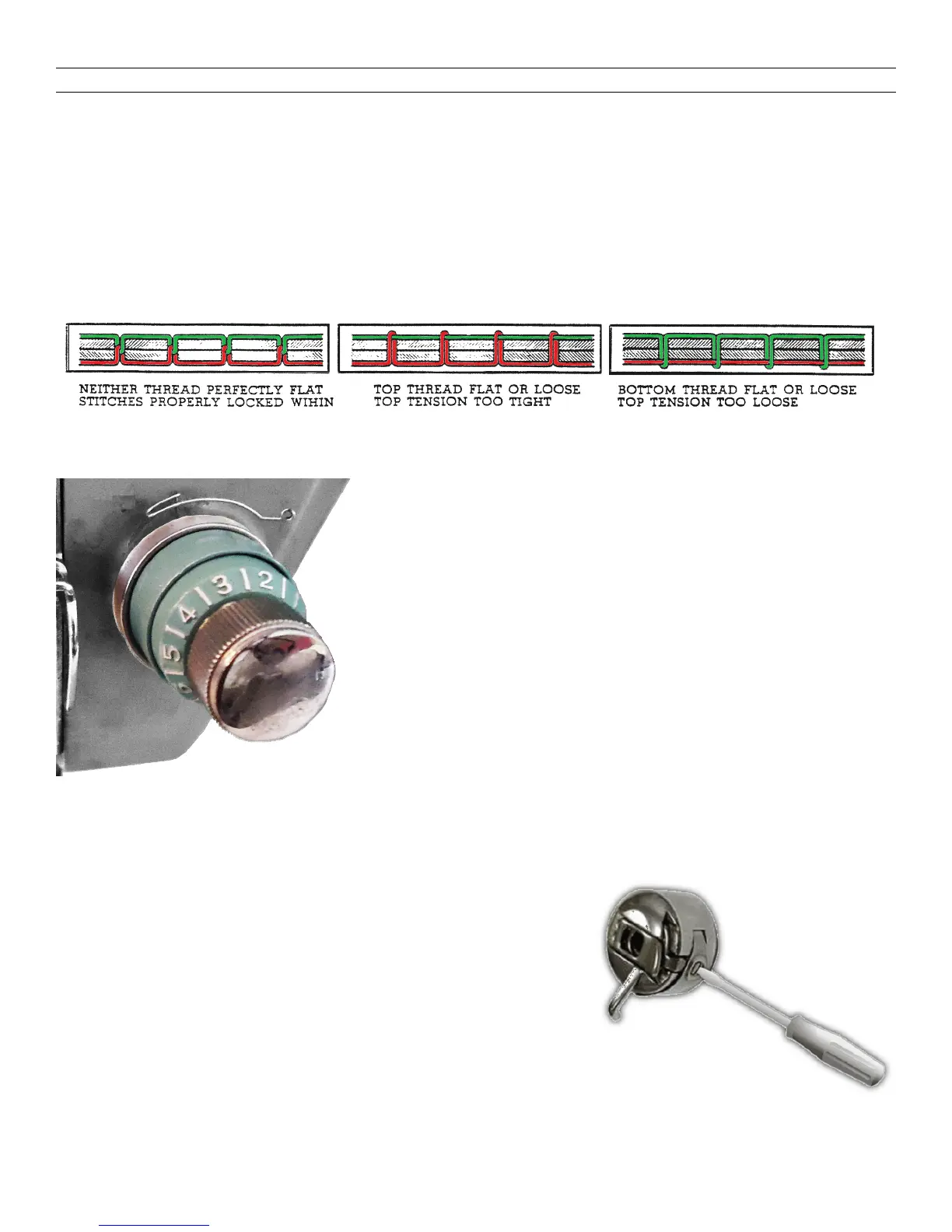

— To Tighten or Loosen Top Tension

First, be sure that the Presser Foot is DOWN —

resting on the fabric. (When raised, the top thread

tension is automatically released.) To TIGHTEN the

needle thread tension, turn the numbered dial

(picture left) CLOCKWISE. To relieve tension, turn

the dial counter-clockwise. The higher the number at

which the dial is set, the heavier the tension on the

needle thread. Before attempting any tension

adjustments be doubly sure that the machine is

completely and properly threaded and that the

Presser Foot is DOWN. If the tension adjustment of

the needle thread does not produce properly balanced stitching, only then do you

consider adjusting the tension on the bobbin case (lower) thread.

To Loosen or Tighten Bobbin Thread Tension —

This adjustment is rarely necessary unless you have

sewing calling for very unusual thread in the bobbin;

for instance, elastic thread. To adjust the tension on

the bobbin thread, merely turn the small screw in the

outer rim of the Bobbin Case (picture right). Turn the

screw a little at a time as you pull thread to test the

tension on it. Turn the screw CLOCKWISE to

INCREASE the tension — the other way ease it.

Loading...

Loading...