36| P a g e

Bonding Patches to Polyurethane Fabric

Caution: Before using a putty knife or any flat-bladed tool on any

inflatable product, ensure that there are no sharp edges or corners on

blade to prevent further damage to material.

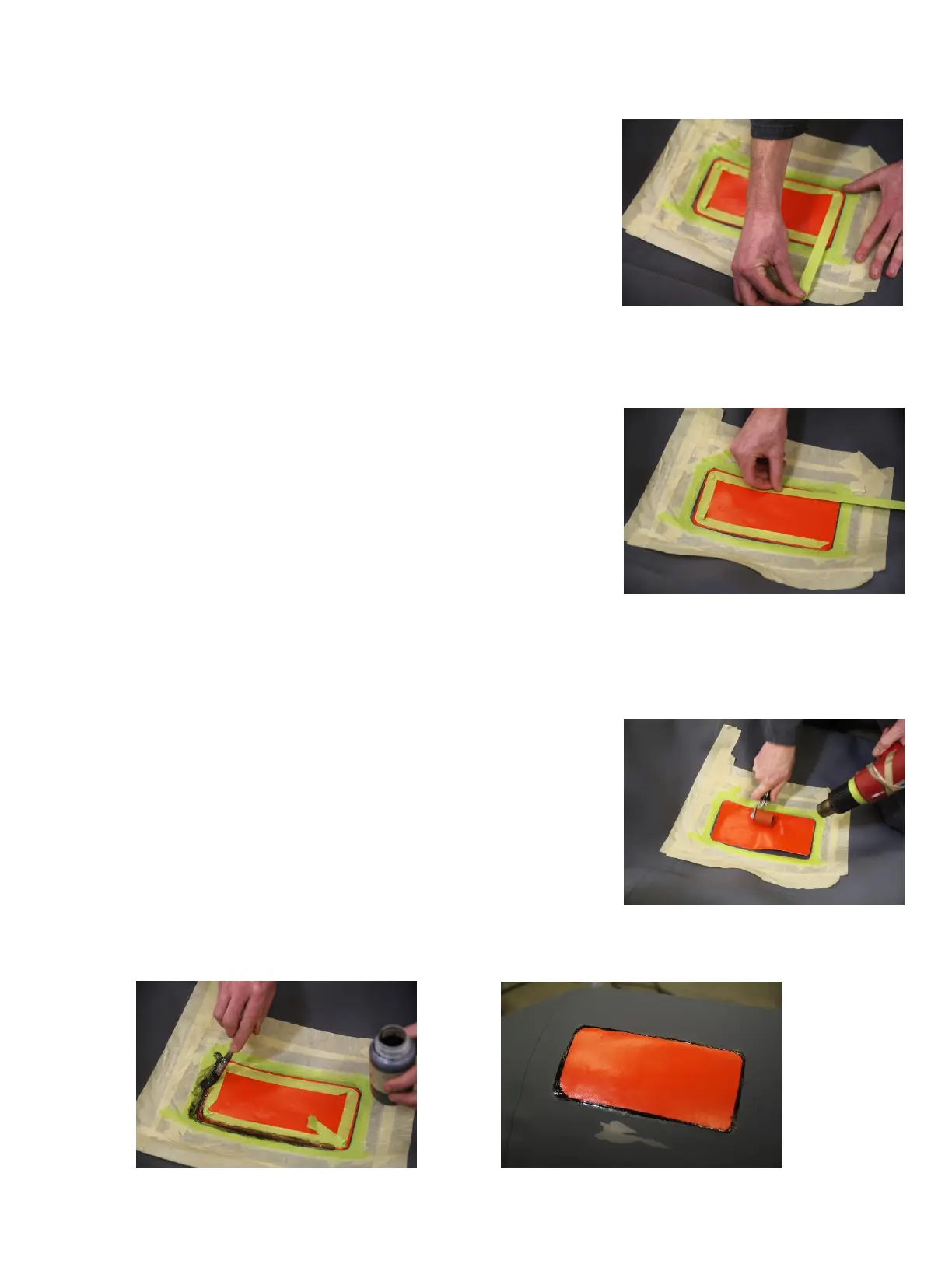

1. Round patch corners to prevent “snagging” when the

boat is back in use.

Line up patch to the taped off area.

2. Starting at one edge, utilize a hair dryer or heat gun to warm both surfaces and apply pressure using putty

knife or hand roller.

The heat activates the adhesive.

NOTE: Do not overheat; the fabric should be warm to the touch, no more!

3. Applying pressure with a putty knife or hand roller, work the patch

down from one edge so as to avoid trapping air bubbles under the patch.

If bonding over seams, take extra care to assure bond between fabric and

patch.

4. If adhesive is warm, patch edges may pull up. Allow adhesive and

patch to cool.

Once cool, lightly run a putty knife around the edges. If an

edge has not adhered, apply more heat and apply pressure. If having problems

with adhesion, see troubleshooting guide at end of section.

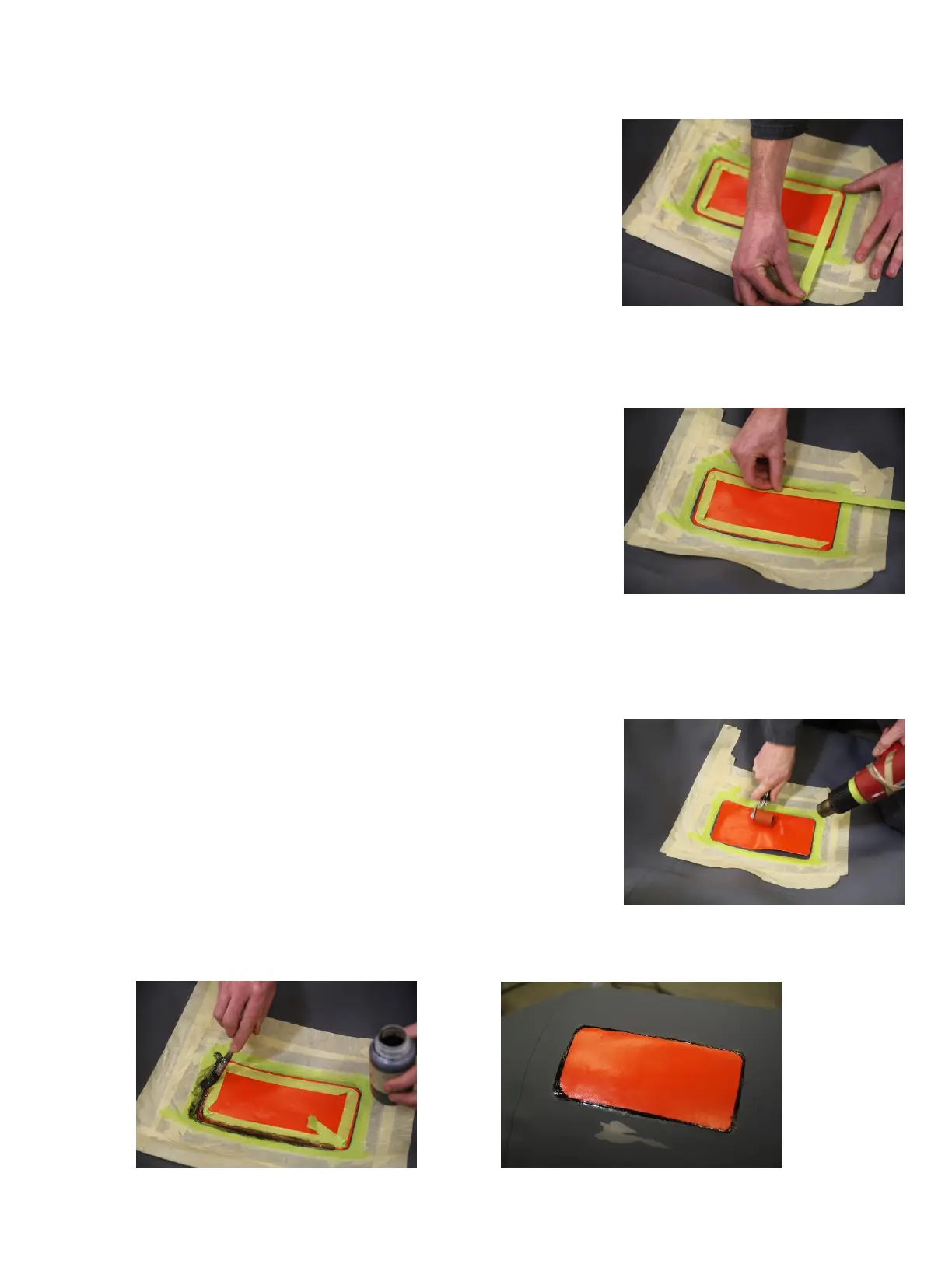

IMPORTANT NOTE REGARDING SEALING EXPOSED EDGES OF

FABRIC:

We recommend utilizing either Clifton one-or two-part adhesive or

Goop to seal the exposed edges of fabric patches against water intrusion and

air loss through patch edges.

5. Tape off the repair area to original sanding lines to hide all repaired

areas (Goop and adhesive WILL NOT STICK if applied outside sanded

areas).

6. Use a brush to apply adhesive or Goop carefully around patch edges.

IMPORTANT NOTE: If using adhesive, let the solvent flash-off.

7. If using Goop, apply immediately after solvent.

Loading...

Loading...