6| P a g e

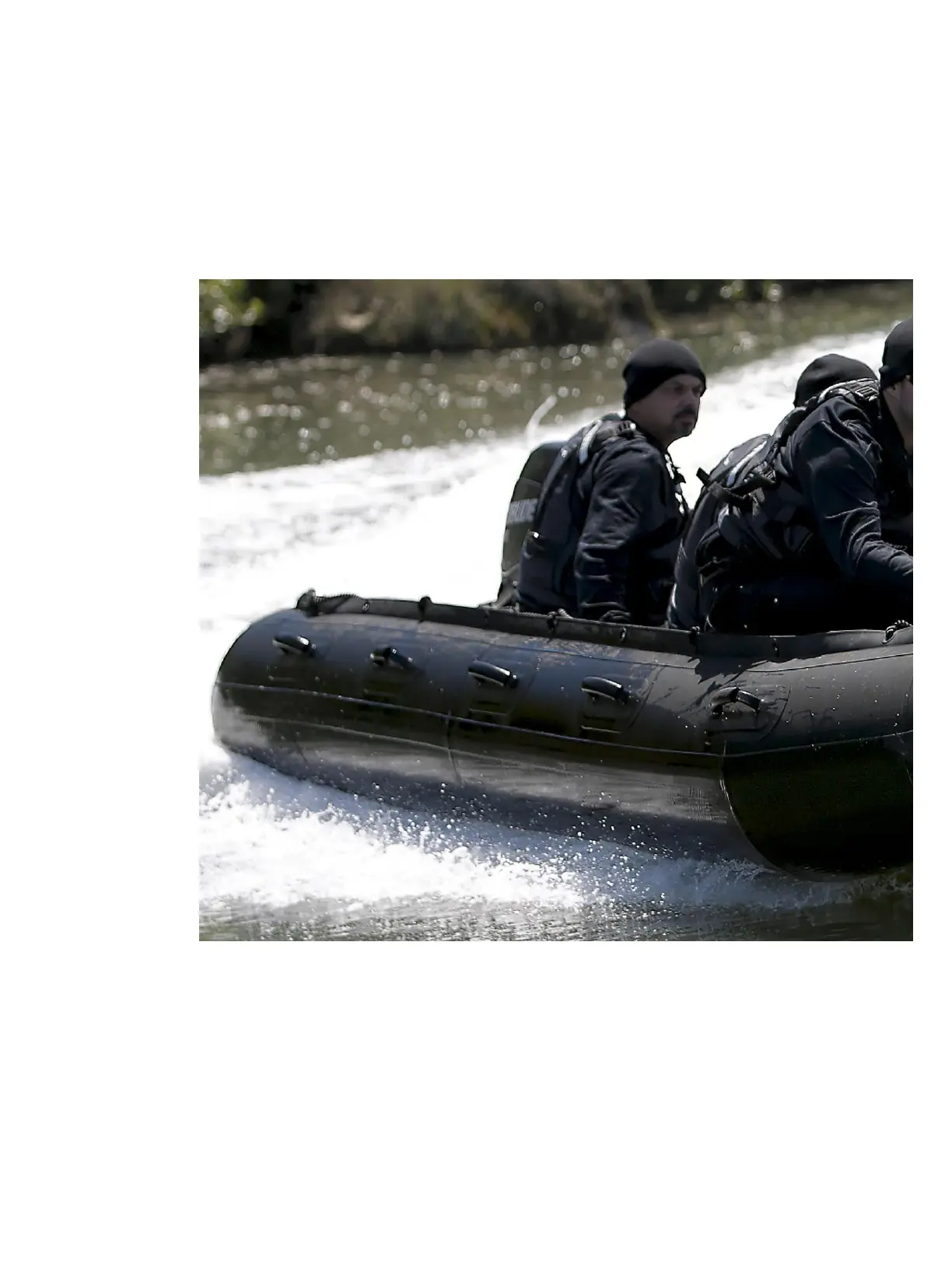

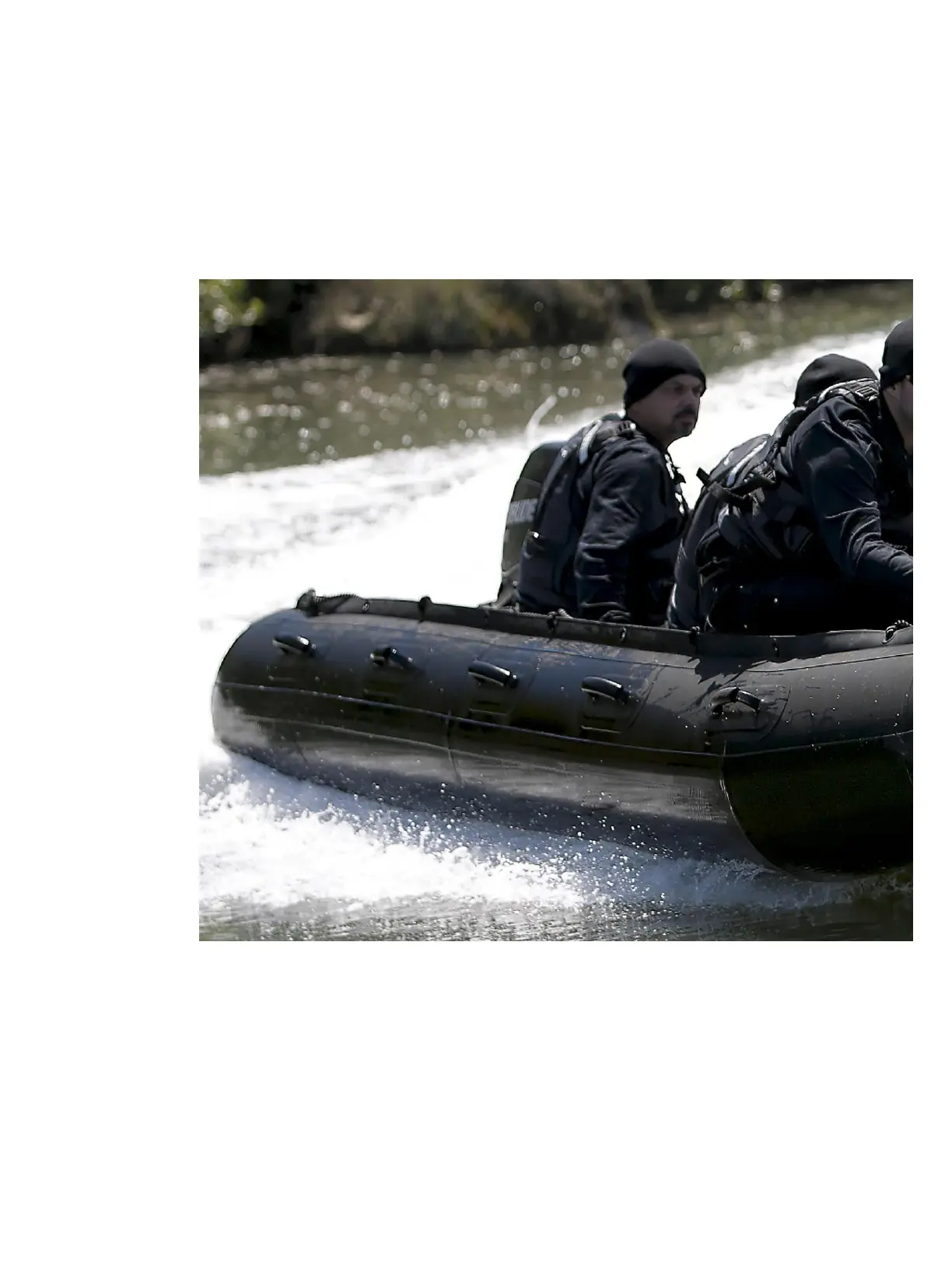

WING CRRCS − TOP OF THEIR CLASS

Seven Key Reasons to Run One

#1 Polyurethane vs. hypalon. A polyester scrim coated with Polyurethane not only gives the Wing CRRC superior

tear, puncture, and abrasion resistance compared to hypalon (CSM) and PVC, the 1680 denier thread count adds

stiffness as well.

Consequently, an

inflated Wing is

more rigid yet

lighter than boats

made with lesser

materials. A

lighter, more rigid

boat is a faster,

more

maneuverable,

more efficient boat

to run.

#2 Thermo-

welded vs. glued

seams. Thermo-

welding bonds two

pieces of coated

fabric together as if

they were one.

Molecularly fused

using heat (not

adhesives as with

hypalon), welded

seams are far more

reliable than glued

seams. Expect a

greatly extended

service life and a

much longer shelf life for boats in long-term storage with welded seams over glued seams.

#3 FRP Composite transom and floorboards vs. plywood/ aluminum. FRP composite is nonabsorbent so it won’t

rot or decay. It is lighter than wood or aluminum and has a superior strength to weight ratio.

Loading...

Loading...